Hi I’m new here and have been slowly build a jaeger rifle and an now to the point of browning the barrel and I’ve never done it before so I was wondering if I should brown it with the vent liner in it or not and what about the sights in it or out?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question about browning

- Thread starter Newbie

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,039

- Reaction score

- 1,424

Welcome to the forum! Lots of good guys and info here.

Leave the vent liner in (or install it first) for sure. If you are using a Whitening those have to be filed flush to the barrel flat. If you brown first and install afterwards you will muck up the finish. Other types that have a screwdriver slot you could do it otherwise I suppose, but no real good reason to.

I suspect your reasoning comes from a concern about rusting the inside of the bore with solution that gets in there, correct? Not a bog deal. If it does a little bit that's only in the chamber area, and that only holds powder anyway. The ball is seated forward of that. Just coat the barrel bore liberally with oil while doing the browning, and you won't have anything to worry about.

Same for the sights. the browning process creates active rust that has to be neutralized afterwards with baking soda or ammonia. You want the rusting process to stop. Brown your sights off the gun and then install. Are you using one of those "upsetting" chisels for the rear, or, installing them flush? Not that it matters that much, but with edged that are bent up, you'll likely have to pound them back down to get a good tight purchase with them.

Leave the vent liner in (or install it first) for sure. If you are using a Whitening those have to be filed flush to the barrel flat. If you brown first and install afterwards you will muck up the finish. Other types that have a screwdriver slot you could do it otherwise I suppose, but no real good reason to.

I suspect your reasoning comes from a concern about rusting the inside of the bore with solution that gets in there, correct? Not a bog deal. If it does a little bit that's only in the chamber area, and that only holds powder anyway. The ball is seated forward of that. Just coat the barrel bore liberally with oil while doing the browning, and you won't have anything to worry about.

Same for the sights. the browning process creates active rust that has to be neutralized afterwards with baking soda or ammonia. You want the rusting process to stop. Brown your sights off the gun and then install. Are you using one of those "upsetting" chisels for the rear, or, installing them flush? Not that it matters that much, but with edged that are bent up, you'll likely have to pound them back down to get a good tight purchase with them.

stewart.leach

32 Cal.

- Joined

- Aug 1, 2007

- Messages

- 177

- Reaction score

- 124

Thanks do you normally have the liner brown when you’re done or do you finish it with something else, the sights will be flush

Most flash hole liners these days are stainless steel, which won't brown. I install the liner with a good coat of automotive anti-seize compound, then wipe off excess thoroughly. Plug the hole in the liner with a bit of beeswax or modeling clay to keep chemicals out of bore. Degrease the whole area well. Similar technique for percussion gun.

Plug the muzzle with a wooden plug. I take a piece of pine about 1 x 1 x 6 inches and rasp a 3 - 4 inch taper on it, and drive into muzzle. Others will say use hardwood, but pine has worked for me.

Lessons learned the hard way the first time I browned:

High humidity and warmth are necessary. Had access to a browning box heated by a light bulb, now use a tube made of 4 inch white plastic pipe with a damp rag in the bottom and a lamp shining on the outside. Tube is vertical, barrel, rib, etc. hang from top using stove wire.

Follow the directions on the Laurel Mtn. Forge carefully as regards carding and neutralizing the chemicals.

Apply a protective finish of oil, paste wax or beeswax. My best results so far have come from warming barrel with a hair dryer and rubbing in beeswax. Use a toothbrush to get protective finish into nooks and crannies like dovetails and threads.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,039

- Reaction score

- 1,424

Having a bright bull's eye like that is actually something of a blessing when you are shooting it. It makes wiping it off and finding the hole for vent pricking it that much easier. Of course, it also makes getting it really well centered more important. Flinters are pretty forgiving as to function and flash hole location, but if it's off center very much from the pan center, it will always look a little bit goofy.

Take your time and measure a few times before you scribe and punch your center mark for the drill punch. Some folks say it doesn't matter if your drill enters at an exact 90 degree angle to the flat or not. I didn't want to find out, so I took a lot of time getting the angle as close to 90 degrees as I could so I would have a solid contact all the way around the liner--no hair line.

Take your time and measure a few times before you scribe and punch your center mark for the drill punch. Some folks say it doesn't matter if your drill enters at an exact 90 degree angle to the flat or not. I didn't want to find out, so I took a lot of time getting the angle as close to 90 degrees as I could so I would have a solid contact all the way around the liner--no hair line.

Don’t want to throw a wrench at your monkey but many original jagars were in the white or blued. They’ve turned brown after years of oxidation. Just some food for thought.

Sidney Smith

58 Cal.

- Joined

- Feb 17, 2019

- Messages

- 2,205

- Reaction score

- 2,312

Definitely install the liner first, and fit it up to the barrel flat(as in file it to the contour of the barrel). As was mentioned, brown the barrel and sights separately. If not, you won't get the browning solution under the sights and you may be able to see the contrast. To brown the barrel, break a tooth pick in half and insert into the flash hole to keep the chemicals from getting inside the bore. Use a pine dowel slightly under size for the muzzle, and wrap masking or painter's tape around one spot on the dowel about two or three inches from the end, in order to increase its diameter until it fits snugly into the bore. This will keep any chemicals out of the muzzle. Then have at it. Browning isn't that hard to do. I prefer the hot brown method such as Plum Brown by Birchwood Casey. It produces a nicer looking finish IMO.

- Joined

- Jan 12, 2005

- Messages

- 1,238

- Reaction score

- 1,655

LMF cold Brown is MUCH more durable than any hot brown. Also, YOU decide whether it's smooth or textured. If taken care of, you'll never have to re do it.

Sidney Smith

58 Cal.

- Joined

- Feb 17, 2019

- Messages

- 2,205

- Reaction score

- 2,312

Laurel Mountain forge produces a crappy finish IMO, and is more time consuming to use. I followed their directions to the letter when I browned my smooth bore's barrel. I was not impressed at all with the results. I'll stick with plum brown and a torch. So far my Lancaster's barrel's finish looks the same as when it was first done, and that's been at least 5 years of hard hunting use now.

all browning solutions will give you a good finish the secret is doing the prep work. make sure the part is completely

free of oil including your fingerprints and sanded or draw filed smooth not shiny just smooth .

The other big secret is read and follow the darn instructions

free of oil including your fingerprints and sanded or draw filed smooth not shiny just smooth .

The other big secret is read and follow the darn instructions

- Joined

- Nov 26, 2005

- Messages

- 5,229

- Reaction score

- 10,918

Hi,

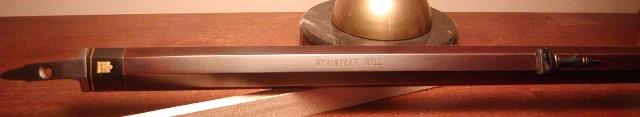

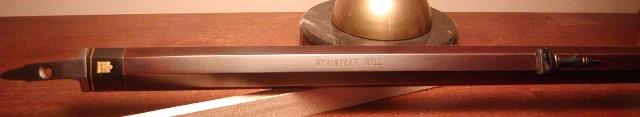

I recently experimented with 4 different browning solutions, Wahkon Bay rust brown, LMF, Tracks's Tried and True, and weak ferric chloride. LMF is the easiest to use because it is also a degreaser. It produces a dark plum colored brown. Tried and True was the worst, uneven, and very dark gray-brown. Wahkon Bay was a little more tricky to use than LMF but offered a warm reddish brown. The ferric chloride solution likely would create the reddest brown but it was very, very slow and it has to be very weak or it will pit the metal. I definitely prefer Wahkon Bay. As others mentioned, metal prep is important but it the brown also depends on how you apply it, how long you let the barrel rust, and how you card. Heat and humidity affect how quickly the barrel rusts but the longer you leave it to rust determines how smooth the browned surface. The longer rusting achieves a quicker brown but the surface will be pitted and textured. Shorter rusting period keeps the surface smoother but you need more cycles of application to get even color. Carding is best done with a soft stainless steel wheel with bristles no larger than 0.003" in diameter and spinning at a slow speed. A toothbrush, Scotch Bright pads, and even the ends of a tight roll of canvas cloth will also work but the wheel is by far the best. When applying the solution, it is best to used a cloth pad, dampen it with solution and apply sparingly on the barrel. Don't mop it on heavily. Particularly with LMF, you will get a copper film if you do, which can retard rusting. Below is a barrel I browned recently with Wahkon Bay.

dave

I recently experimented with 4 different browning solutions, Wahkon Bay rust brown, LMF, Tracks's Tried and True, and weak ferric chloride. LMF is the easiest to use because it is also a degreaser. It produces a dark plum colored brown. Tried and True was the worst, uneven, and very dark gray-brown. Wahkon Bay was a little more tricky to use than LMF but offered a warm reddish brown. The ferric chloride solution likely would create the reddest brown but it was very, very slow and it has to be very weak or it will pit the metal. I definitely prefer Wahkon Bay. As others mentioned, metal prep is important but it the brown also depends on how you apply it, how long you let the barrel rust, and how you card. Heat and humidity affect how quickly the barrel rusts but the longer you leave it to rust determines how smooth the browned surface. The longer rusting achieves a quicker brown but the surface will be pitted and textured. Shorter rusting period keeps the surface smoother but you need more cycles of application to get even color. Carding is best done with a soft stainless steel wheel with bristles no larger than 0.003" in diameter and spinning at a slow speed. A toothbrush, Scotch Bright pads, and even the ends of a tight roll of canvas cloth will also work but the wheel is by far the best. When applying the solution, it is best to used a cloth pad, dampen it with solution and apply sparingly on the barrel. Don't mop it on heavily. Particularly with LMF, you will get a copper film if you do, which can retard rusting. Below is a barrel I browned recently with Wahkon Bay.

dave

Similar threads

- Replies

- 28

- Views

- 948

- Replies

- 147

- Views

- 5K