You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ramrod Ends

- Thread starter doc623

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

when in doubt, go to track of the wolf an check it out

http://trackofthewolf.com/(S(2cxfv...s/tableList.aspx?catID=6&subID=49&styleID=164

http://trackofthewolf.com/(S(2cxfv...s/tableList.aspx?catID=6&subID=49&styleID=164

Last edited by a moderator:

rafterob

62 Cal.

TOW worked for me. If you don't have a range rod, I highly suggest getting one for range sessions and save the ramrod for hunting and woodwalks

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Are you referring to the metal ferrule on the end of some ramrods- those wooden rods fitted to the pipe under the barrel/false rib-- on your rifle, or did you break off a short part of the WOOD????

If you want to replace wood, you need to get access to a wood lathe, and turn out appropriately shaped ends. Check with Arrow Makers ( traditional) to find out how a " footed " shaft is constructed, to learn how best to attach the new end to an older rod.

If you are replaceing the brass( usually) or steel ferrule, they are available from most suppliers. The reference to Track(TOTW) shows the wide variety of shapes and styles now available. What is NOT shown is the need to pin these ferrules to your rod, in addition to gluing them.

Please don't ask me how I learned the importance of pinning the ferrules to my ramrod! :surrender: :hmm: :rotf: :rotf: :hatsoff:

If you want to replace wood, you need to get access to a wood lathe, and turn out appropriately shaped ends. Check with Arrow Makers ( traditional) to find out how a " footed " shaft is constructed, to learn how best to attach the new end to an older rod.

If you are replaceing the brass( usually) or steel ferrule, they are available from most suppliers. The reference to Track(TOTW) shows the wide variety of shapes and styles now available. What is NOT shown is the need to pin these ferrules to your rod, in addition to gluing them.

Please don't ask me how I learned the importance of pinning the ferrules to my ramrod! :surrender: :hmm: :rotf: :rotf: :hatsoff:

I've used T.O.T.W.'s tips. The only real preference I have is to pin it on after cementing. Drill a 1/16" or 3/32" hole through wood and tip after cementing it on and set a finishing nail (brass or iron to match the tip) and file it flush.

Make sure you get the proper thread size. (10-32 or 8-32) to match your attachments.

Make sure you get the proper thread size. (10-32 or 8-32) to match your attachments.

blacksmithman64

50 Cal.

- Joined

- Jan 2, 2007

- Messages

- 1,114

- Reaction score

- 1

Just one thing, after you glue it and pin it, PEEN it just a little.....trust me! :grin:

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Doc: As others have said, check the other suppliers. You can find most of them( with websites) listed in the " Links" section in Member Resources, at the top of the index page to this forum. Prices occassionally vary even for these small components.

I don't have a preference. I believe most are made by the same manufacturer. I buy my on trips to Friendship, rather than through the mail. I find that some suppliers don't seem to employ people who know the difference between an 8-32, and a 10-32 threaded ferrule. The companies always accept the returns and send the correct parts back, but its a hassle. I find it easier to just pick them out myself from the dealers on commercial row.

I have used brazing rod to pin my ferrules. I can't remember the correct size drill bit, but that was easy enough to determine after measuring the brazing rod with my micrometer. The Brazing rod is a hard, nickel/copper alloy, but peens over easily, and hold fast. The rod is smaller in diameter than a common nail, so I have used that. However, if you have small nails, find a drill bit the size of the nail, and use that. Just snip off the ends with wire cutters, and peen the ends with a hammer. I then like to file the ends off so nothing sticks about the surface of the ferrule. Peening not only mashes the ends, but swells the rest of the pin inside the wood, locking it in place. By using the brazing rod, I don't have to deal with rust, and any oxidation of the brazing rod makes the pin blend better with the brass ferrule.

One shooter expressed surprise when he finally spotted the pin in my ferrule, telling me that from a distance, he didn't think my ferrule was pinned.

I don't have a preference. I believe most are made by the same manufacturer. I buy my on trips to Friendship, rather than through the mail. I find that some suppliers don't seem to employ people who know the difference between an 8-32, and a 10-32 threaded ferrule. The companies always accept the returns and send the correct parts back, but its a hassle. I find it easier to just pick them out myself from the dealers on commercial row.

I have used brazing rod to pin my ferrules. I can't remember the correct size drill bit, but that was easy enough to determine after measuring the brazing rod with my micrometer. The Brazing rod is a hard, nickel/copper alloy, but peens over easily, and hold fast. The rod is smaller in diameter than a common nail, so I have used that. However, if you have small nails, find a drill bit the size of the nail, and use that. Just snip off the ends with wire cutters, and peen the ends with a hammer. I then like to file the ends off so nothing sticks about the surface of the ferrule. Peening not only mashes the ends, but swells the rest of the pin inside the wood, locking it in place. By using the brazing rod, I don't have to deal with rust, and any oxidation of the brazing rod makes the pin blend better with the brass ferrule.

One shooter expressed surprise when he finally spotted the pin in my ferrule, telling me that from a distance, he didn't think my ferrule was pinned.

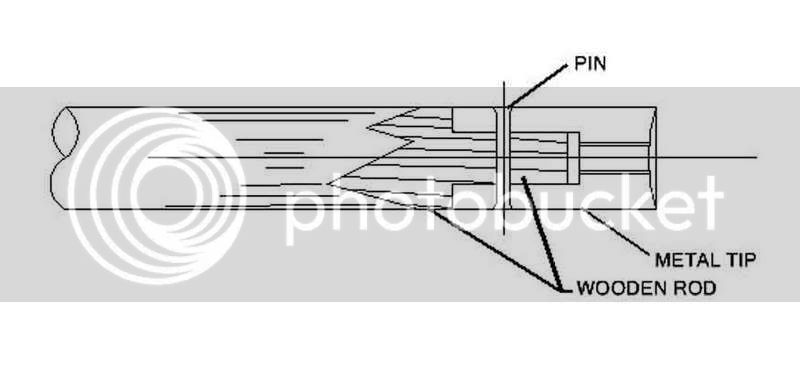

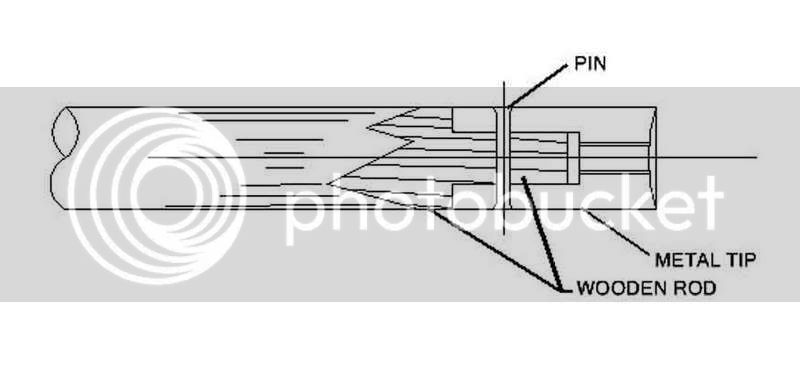

Maybe to clarify the pinning a bit this picture would help.

When installing a new tip on a new ramrod I measure the depth of the hole in the tip and then subtract maybe 1/16 of an inch or a little less from that value.

Then I make a mark on my new ramrod at that dimension from the end.

Using a very sharp knife placed on the mark I then roll the ramrod so the knife cuts a little grooveall around the rod.

I repeat this rolling with a knife until it has cut about 1/32 of an inch into the wood.

Then taking the knife I cut from the short end of the rod at an angle to intersect the previous cut.

After I've got these angular cuts down to the depth of the circular cut I use a smooth toothed flat file to file the remaining wood down to match the hole in the tip.

While your doing this, try the tip several times.

A point will be reached where you can "screw" the tip onto the wood. By removing the tip you can see the polished areas that need a little more filing.

When the tip will fit all of the way to the shoulder you made with the knife apply some 2 part Epoxy to the outside of the rod end and to the hole in the new tip and slide it up so it is tight with the shoulder of wood.

Use a 1/16 diameter drill to drill the hole thru the metal tip and the wood.

When this hole is done, use your pocket knife tip stuck into the hole and rotate it several times.

This will form a little countersink.

Repeat this on the other sides hole.

Find a piece of brass, copper or steel wire that is 1/16 of an inch in diameter and press it thru the hole.

Cut the ends of the wire off so they are just a little "proud" of the outside of the metal end.

Then use a hammer to gently pound the protruding ends down into the countersink you made with your knife.

Now, use your fine toothed file to file the remaining part of the wire that is still sticking up so it's flush with the outside of the metal tip.

Stain the wood if you want it darker and apply a few coats of linseed oil, tung oil or even varnish to finish it off.

When installing a new tip on a new ramrod I measure the depth of the hole in the tip and then subtract maybe 1/16 of an inch or a little less from that value.

Then I make a mark on my new ramrod at that dimension from the end.

Using a very sharp knife placed on the mark I then roll the ramrod so the knife cuts a little grooveall around the rod.

I repeat this rolling with a knife until it has cut about 1/32 of an inch into the wood.

Then taking the knife I cut from the short end of the rod at an angle to intersect the previous cut.

After I've got these angular cuts down to the depth of the circular cut I use a smooth toothed flat file to file the remaining wood down to match the hole in the tip.

While your doing this, try the tip several times.

A point will be reached where you can "screw" the tip onto the wood. By removing the tip you can see the polished areas that need a little more filing.

When the tip will fit all of the way to the shoulder you made with the knife apply some 2 part Epoxy to the outside of the rod end and to the hole in the new tip and slide it up so it is tight with the shoulder of wood.

Use a 1/16 diameter drill to drill the hole thru the metal tip and the wood.

When this hole is done, use your pocket knife tip stuck into the hole and rotate it several times.

This will form a little countersink.

Repeat this on the other sides hole.

Find a piece of brass, copper or steel wire that is 1/16 of an inch in diameter and press it thru the hole.

Cut the ends of the wire off so they are just a little "proud" of the outside of the metal end.

Then use a hammer to gently pound the protruding ends down into the countersink you made with your knife.

Now, use your fine toothed file to file the remaining part of the wire that is still sticking up so it's flush with the outside of the metal tip.

Stain the wood if you want it darker and apply a few coats of linseed oil, tung oil or even varnish to finish it off.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,537

- Reaction score

- 94

Thanks for the drawing and description, Zonie. I think this should be a big help for anyone contemplating doing this chore. :hatsoff:

I ususlly double-pin mine. First one is about 3/16" from the left end (as shown on Zonie's drawing) and the second one is 1/4" to the right of #1 and rotated 90 degrees. I figure two has got to be better than one, right?

Guest

Zonie has got it right. The only thing I do differently is to put ferrules on both ends of the rod, one threaded for 10X32 and one for 8X32. That way if you need to borrow a tip it doesn't matter what the thread size is.

Mark

Mark

longcruise

70 Cal.

The only thing I do differently is to put ferrules on both ends of the rod, one threaded for 10X32 and one for 8X32.

That's a great idea. I've accumulated a bunch of both thread sizes in various calibers and don't always grab the right one on the way out the door!

One thing I'll add to Zonie's tutorial is this. Many of the ramrod tips are open between the threaded cavity and the rod receptacle cavity. Before glueing I take a tiny piece of beeswax and push it into the opening at the bottom of the threaded receptacle so as to keep glue form getting into the threads. Learned that the hard way. :redface:

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,213

I make all of mine myself. Do you know someone with a metal lathe and a little brass?. They are simple to make and you can make them a little longer or shorter than "standard". Also I put tapped brass ends on both ends. It makes it easy to screw on a "T" handle to pull out a stuck cleaning patch.

Guest

Ohio Ramrod,

Right again. I also carry a piece of steel rod, 3/8"X 4". I file a flat in the middle with a 3/16" hole in the center. In each end I drill and tap an 8X32 hole and a 10X32 hole. I store an appropriate size screw in each hole and I have a "T" handle for whatever size is needed.

Mark

Right again. I also carry a piece of steel rod, 3/8"X 4". I file a flat in the middle with a 3/16" hole in the center. In each end I drill and tap an 8X32 hole and a 10X32 hole. I store an appropriate size screw in each hole and I have a "T" handle for whatever size is needed.

Mark

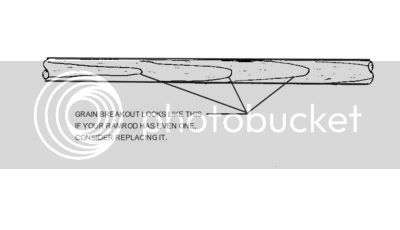

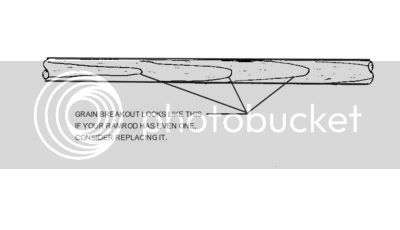

Doc: If your going to go to a lumber yard to buy your ramrod blank make sure it does not have any grain runout anywhere along its length.

The folks at lumber yards don't understand how important it is for the rod to NOT have grain runout so they may try to sell you some stock that has it.

I've even seen some ramrod blanks from some pretty reputable black powder supply places that had runout. I'm not sure why they didn't screen their stock and throw away the bad rods but they didn't.

Anyway, grain runout like I drew in the picture signifies that the grain is not running the full length of the rod. That causes a weak place that can easily break while ramming a ball and more than one muzzleloader has shoved a broken ramrod thru his hand or wrist.

Happy ramrod hunting.

The folks at lumber yards don't understand how important it is for the rod to NOT have grain runout so they may try to sell you some stock that has it.

I've even seen some ramrod blanks from some pretty reputable black powder supply places that had runout. I'm not sure why they didn't screen their stock and throw away the bad rods but they didn't.

Anyway, grain runout like I drew in the picture signifies that the grain is not running the full length of the rod. That causes a weak place that can easily break while ramming a ball and more than one muzzleloader has shoved a broken ramrod thru his hand or wrist.

Happy ramrod hunting.

longcruise

70 Cal.

Hickory is not common in my area. Would like to find a source of hickory dowells!

One way to avoid runout is to buy a straight grained hickory board and split blanks out of it. They will follow the grain and when worked down to a dowel will be runout free.

One way to avoid runout is to buy a straight grained hickory board and split blanks out of it. They will follow the grain and when worked down to a dowel will be runout free.

Thanks for the tip of the 'run out'.

I am checking with a local lumber store.

They do have the rod diameter I am looking for in 36" lengths so that does not seem to be a problem. The price is approx $2.00/dowel. Not certain but I will know in a day or two.

If anyone needs any I will be glad to get and send for actual cost and actual shipping as a return favor for the help I have received here. Maybe others can find the dowel rods at a better price but I thought that I would offer.

I am checking with a local lumber store.

They do have the rod diameter I am looking for in 36" lengths so that does not seem to be a problem. The price is approx $2.00/dowel. Not certain but I will know in a day or two.

If anyone needs any I will be glad to get and send for actual cost and actual shipping as a return favor for the help I have received here. Maybe others can find the dowel rods at a better price but I thought that I would offer.

Similar threads

- Replies

- 12

- Views

- 699

- Replies

- 7

- Views

- 501

- Replies

- 3

- Views

- 702