Hi KV,

Davis locks are OK and are a major step up from L&R, which are the bottom of the heap. Their designs are pretty good although the Twigg lock needs the tumbler moved forward by 1/16-3/32" to correct flaws in its geometry. The big jaeger lock is pretty good but it is massive and needs the mainspring strengthened. Likewise the Harper's Ferry lock has weak springs that need strengthening. I forged new main and frizzen springs for it and it is a fine utilitarian lock.

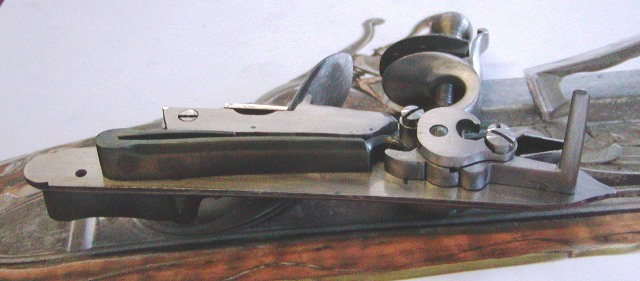

The early American colonial lock is good and is also quite large, and is perhaps Davis' best lock. However, the the flintcock and frizzen are huge and often look too large for the gun. Fortunately, a flintcock from Chambers' early Ketland lock fits perfectly and makes a better looking lock along with grinding the frizzen a little lower. Here is one with the outline of the plate altered

Davis' late English flintlock is a good design but suffers a bit from execution. It has a short throw for the flintcock, as many English locks of that time did, which requires a stout mainspring. Unfortunately, the mainspring is weak and needs to be strengthened considerably. In addition the roller frizzen spring was poorly positioned such that the roller rubbed the toe of the frizzen on one side, not dead center. The frizzen actually pushed the roller and spring out away from the plate. That was easily corrected and it can be made into a first rate late flint English lock.

I also found the lock benefited from a thick sole on the face of the frizzen, which added mass to the frizzen and improved performance quite a bit, particularly when the lock was dirty from firing and flint worn.

I've had some quality control issues with Davis locks. On the early American colonial lock voids in the lock plate bolster where the rear bolt had to go required welding to fix. In addition, Davis always uses the same tiny screws in their locks regardless of how big it is. I wish on the bigger locks they would choose larger screws. All in all, they can be fine locks if you work them over a bit and they are much better than L&R. M&G locks (Larry Zorne) are very similar to Davis. Here is a M&G lock that I worked over.

Before:

After

I've recently had a Danny Caywood lock in my shop to work over. It was from an older Caywood English trade gun, and whoever made it knew what he was about. It was a fine lock that just needed a little tweaking of the springs.

With respect to commercially made locks readily available to makers in America and Canada, there is a definite hierarchy of design and quality. The top of the heap is Chris Laubach's CNC machined Germanic jaeger lock. The entire lock is cut from steel stock except the springs, which are forged. The inside and outside are polished to the equivalent of 400 grit paper so it is the only lock I am comfortable with taking out of the box, installing, and going right to the engraving bench without working on it. Next are Jim Kibler's offerings, which are mostly CNC machined but use cast frizzens and flintcocks. I will tweak the one on my bench right now a little but it is basically fine right out of the box. Unlike Laubach's lock, the outside needs to be polished before engraving or finishing. Next are all of Jim Chambers' offerings. They need work on the outside and benefit from polishing the internals as well as balancing the springs. However, they are superb locks. If Caywood's current production is as good as the older lock I worked on, his locks are equal to Chambers in every measure. Stan Hollenbaugh also makes a suite of locks of the same quality of design and construction. After those makers comes Davis and perhaps M&G. At the bottom by a good measure is L&R.

The very finest locks I've ever experienced, including original English locks, are the two Wogdon locks, I built from castings by E. J. Blackley.

dave