I been working on this project for sometime now.

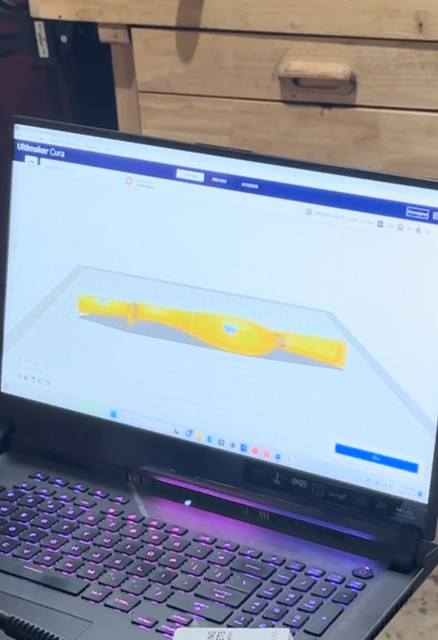

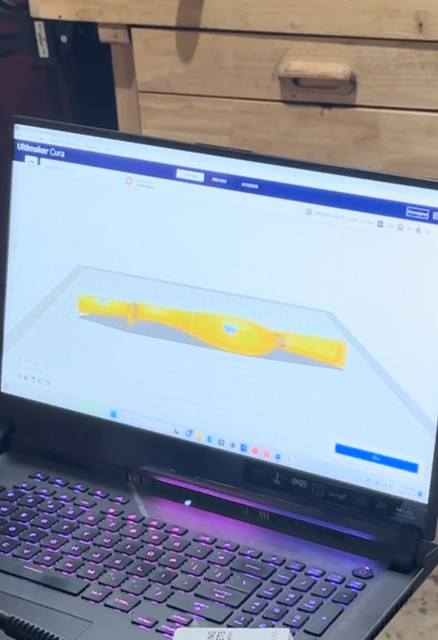

Taking original JP Beck hardware and having it digitally scanned to .001mm I then had it 3D printed to .01mm tolerances in plastic.

Those 3D models were scaled to account for brass shrinkage and clean up.

I made the cope and drag from some oak.

I plan to use finer sand than 130 mesh next time and pack it a little tighter.

See the YouTube video below I made showing my progress/process:

Please share any advice, or tips. Hopefully I will try some butt plates next.

Want my Next build to be all me except for the lock and barrel. Through maybe one day those two ?

Taking original JP Beck hardware and having it digitally scanned to .001mm I then had it 3D printed to .01mm tolerances in plastic.

Those 3D models were scaled to account for brass shrinkage and clean up.

I made the cope and drag from some oak.

I plan to use finer sand than 130 mesh next time and pack it a little tighter.

See the YouTube video below I made showing my progress/process:

Please share any advice, or tips. Hopefully I will try some butt plates next.

Want my Next build to be all me except for the lock and barrel. Through maybe one day those two ?