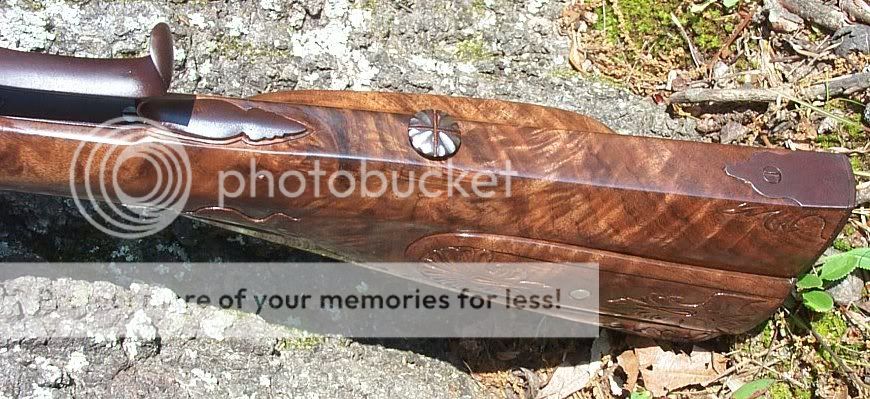

I have a real nice 95% + striped maple stock that is going to be a Kentucky Half stock Hawkens if that makes sense :grin:

I started sanding on it this evening and realize that I don't know if I should sand the stock from butt to forend ... or sand it vertically "with" the tiger stripes ?? TIA !!

I started sanding on it this evening and realize that I don't know if I should sand the stock from butt to forend ... or sand it vertically "with" the tiger stripes ?? TIA !!