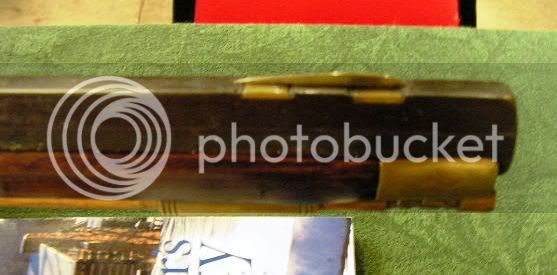

MeteorMan said:I'd appreciate some 'splaining on how to remove (or minimize)depth, from tang to trigger plate.

Going from top to bottom:

Seems like once the barrel is in, that largely dictates the top plane of the lock/forewrist area, and also of course dictates lock placement, which dictates trigger placement, which largely dictates trigger plate placement, which determines the bottom, ventral plane of the lock area.

Where in that chain of hardware can I keep things shorter, smaller, tighter together - to get the slim look ?

I usually measure and draw out all of the lines on the stock. For example, the line of the bottom of the barrel channel, a line representing the top and bottom of the RR hole, and mark the web, between the bottom of the barrel channel and top of the RR hole with cross hatching, to keep all of those lines straight.

If the web is too thick, inlet the barrel deeper...provided the lock mortise is not inlet. I prefer to inlet my own locks, so's I can move things around to make 'em fit the way I want.

If the lock is pre-inlet, ya gotta remove material from the bottom to get all of those parts where they should go.

Personally, I would go with what you have, on this one, and keep all of the good advice you have received for your next build....and there will be a next build. :wink:

IMHO, all in all, I like it.

BTW, Packdog knows his stuff, and birddog ain't no slouch either, so listen to their advice.

God bless