You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TC Renegade unknown plug?

- Thread starter 337

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That is the manufacturing access created when T/C drilled the flash channel from the powder chamber to the nipple seat. Its plugged to prevent someone thinking its a clean out screw and buggering it up and trying to get a replacement breech as happened to the very weak screw T/C used to block the earlier manufacturing hole that was called a "clean out screw". T/C replaced a lot of breech plugs because the soft screw slot was ruined by over tightening and ill fitting screw drivers.

That's a common TC factory breach in later yr models.

With previous models they "used to" drill in a "snail" manner that required multiple milling passes to achieve, along with the clean out screw to create the fire channel.

They learned that a simple cross drill and pressed plug worked just as well.

It's all good,

Besides,, those "clean-out screws" seized up 80% or more of the time from neglect.

We see those posts all the time,,"My clean-out screw is stuck","what should I do?"

Best advice,(?) Forget it's there,, silver solder it closed and polish the surface,,

With previous models they "used to" drill in a "snail" manner that required multiple milling passes to achieve, along with the clean out screw to create the fire channel.

They learned that a simple cross drill and pressed plug worked just as well.

It's all good,

Besides,, those "clean-out screws" seized up 80% or more of the time from neglect.

We see those posts all the time,,"My clean-out screw is stuck","what should I do?"

Best advice,(?) Forget it's there,, silver solder it closed and polish the surface,,

Last edited:

Idaholewis

40 Cal

- Joined

- Jun 29, 2017

- Messages

- 339

- Reaction score

- 636

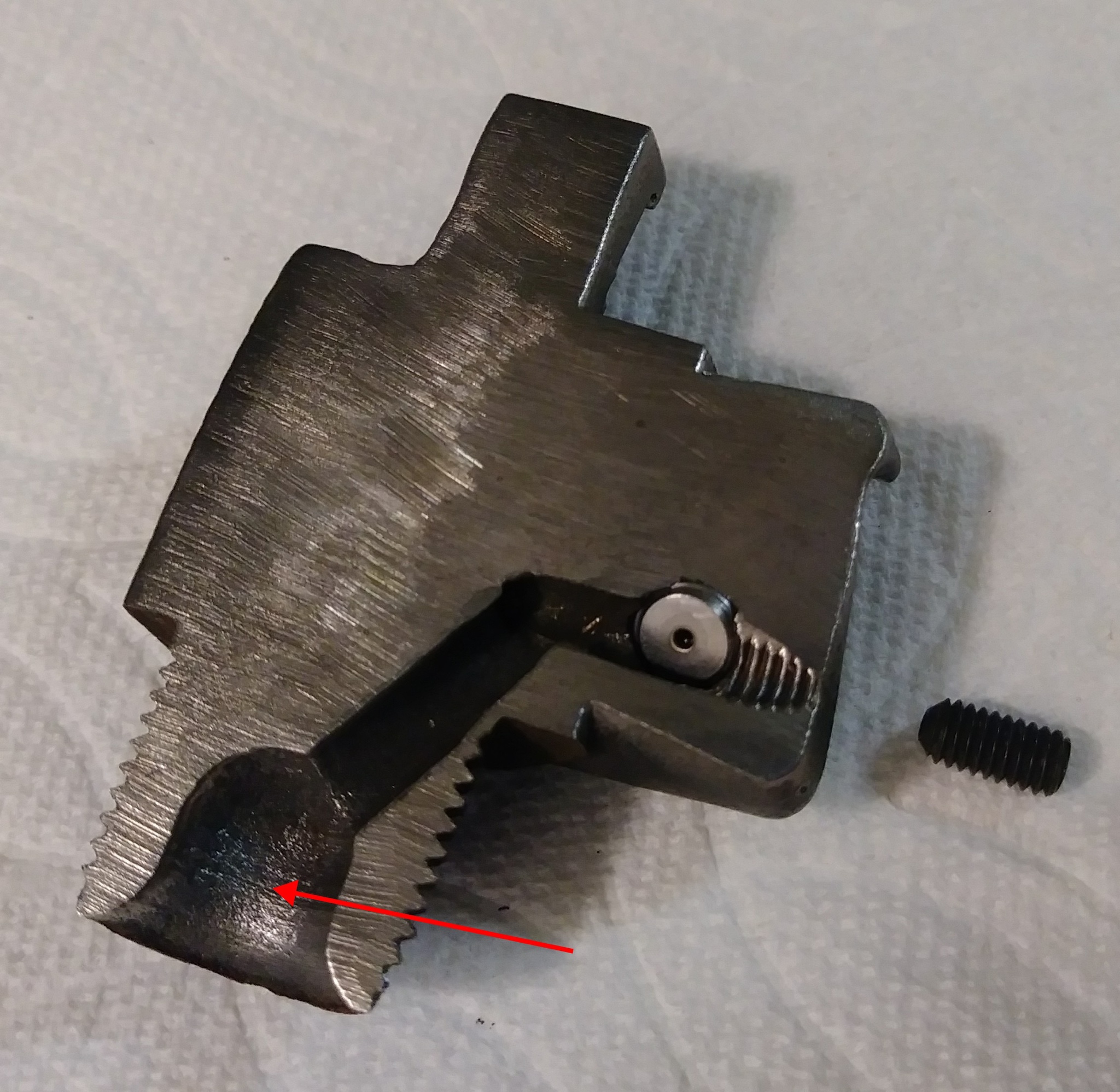

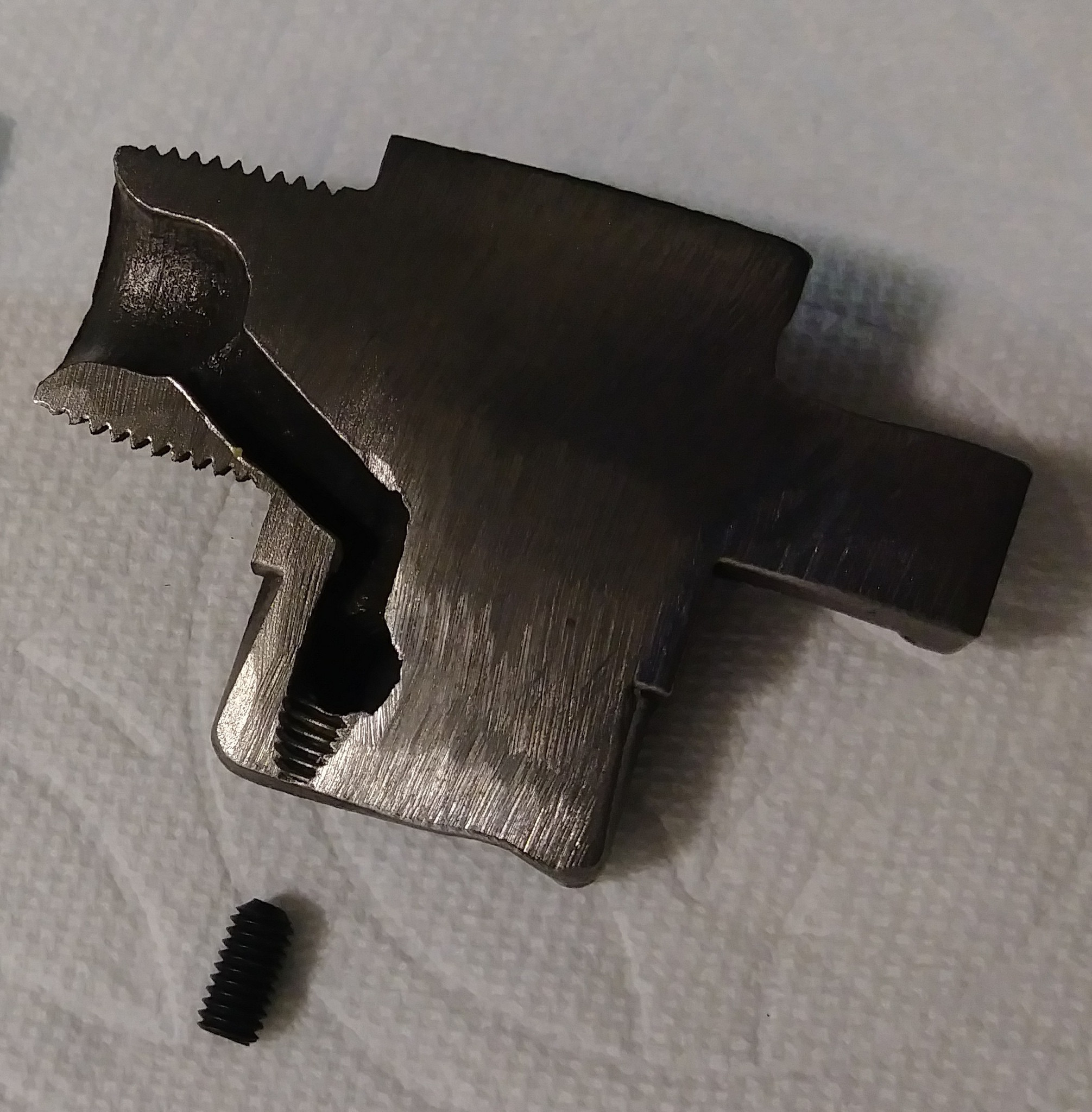

I pulled the Old TC Renegade Breech plug back out again, and popped the Barrel piece off, This is to show up close Detail of how these things were Made. Some have these Visible “Clean Out“ Screws on the side, and Some Don’t (The ones that Don’t, Actually do  ) The ones that Don’t have the Visible “Cleanout Screw” If you look closely on the Opposite side you will see a Flush Plug that is NON Removable. It is doing the EXACT same thing as the Visible “Clean out” Screw, it connects the Powder Chamber/Fire Channel Hole over to, and under the Nipple. But instead of using a Removable “Clean Out“ Screw on these ones, They used a Solid piece of Rod Stock Material to Permanently plug the Hole, they then cut it off Flush and Blue over it.

) The ones that Don’t have the Visible “Cleanout Screw” If you look closely on the Opposite side you will see a Flush Plug that is NON Removable. It is doing the EXACT same thing as the Visible “Clean out” Screw, it connects the Powder Chamber/Fire Channel Hole over to, and under the Nipple. But instead of using a Removable “Clean Out“ Screw on these ones, They used a Solid piece of Rod Stock Material to Permanently plug the Hole, they then cut it off Flush and Blue over it.

This TC Breech Plug has the Visible, Removable “Cleanout Screw” I Personally LEAVE THESE ALONE!, There is NO NEED to remove this Screw for Cleaning. It was put there because it HAD to be, due to the Way they were made, Obviously They HAD to Plug this Hole somehow. You will see Below

Again, If your Rifle does NOT have the Visible Cleanout Screw, Look CLOSELY on the Opposite Side and you will Spot it, Sometimes they Blend in pretty good, But you will See it Here is a TC Renegade WITHOUT The Visible “Clean Out“ Screw on the Side, as i Explained above, this one comes in from the Opposite Side, and is Cut off Flush, Then blued over. It is NOT uncommon to see a Small Gap around the edge of these Flush Cut plugs, like this.

Here is a TC Renegade WITHOUT The Visible “Clean Out“ Screw on the Side, as i Explained above, this one comes in from the Opposite Side, and is Cut off Flush, Then blued over. It is NOT uncommon to see a Small Gap around the edge of these Flush Cut plugs, like this.

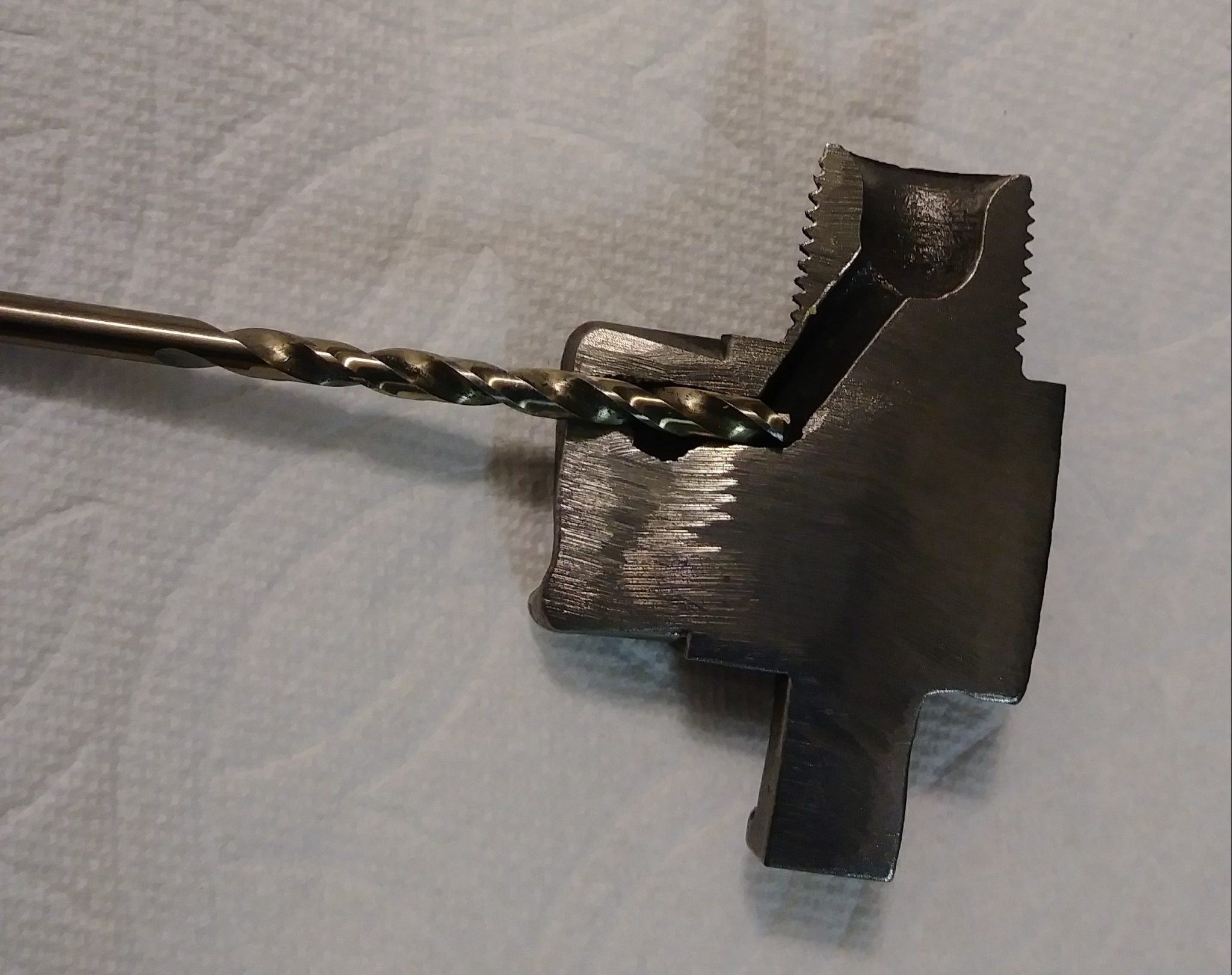

Here you can see the Cut-Away Breech plug (Right) and the Barrel piece (Left) I simply popped them Apart for this Photo tutorial

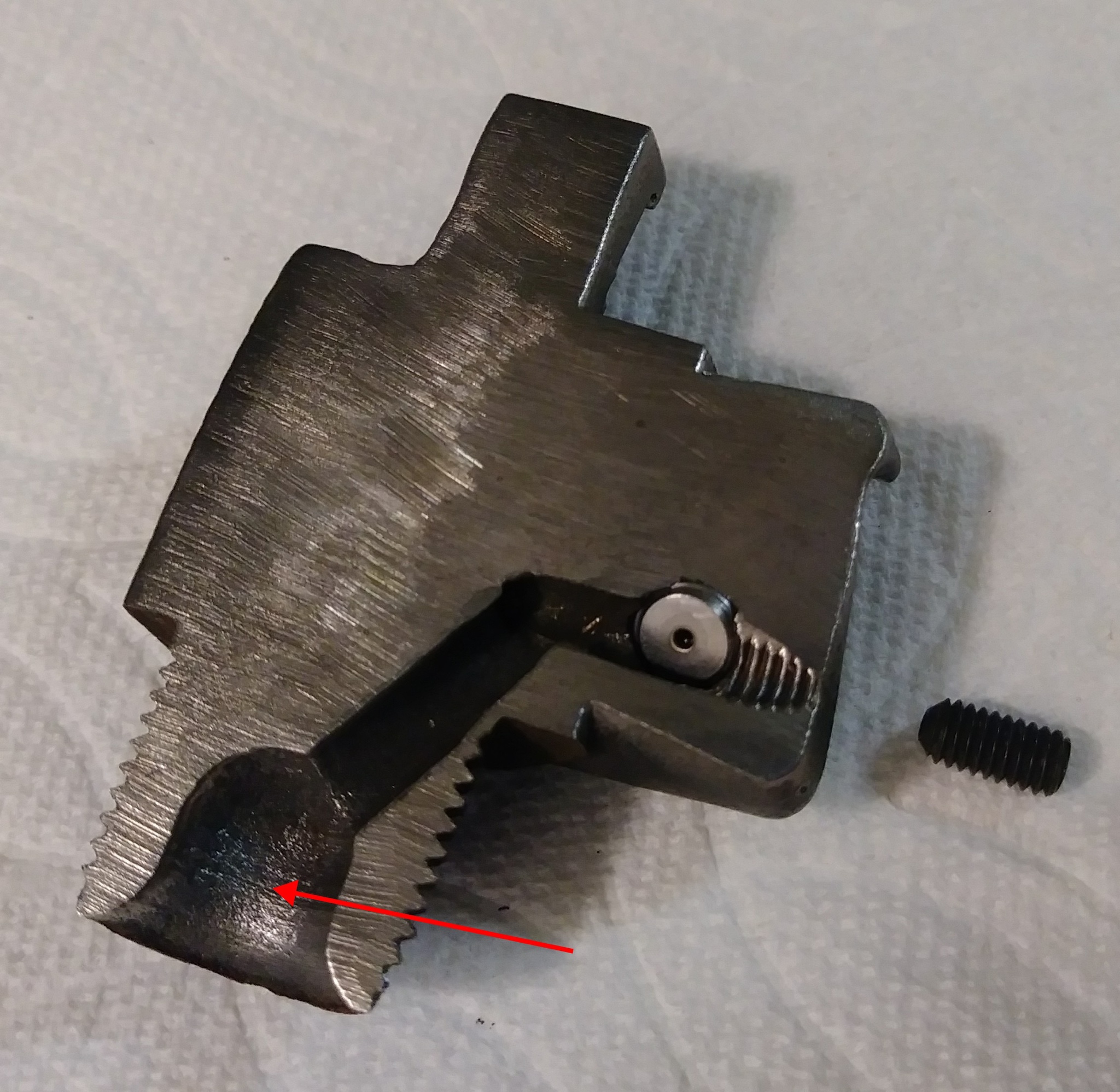

Red Arrow Pointing at the Patented Breech/Powder Chamber

TC made a “Scraper Tool“ to fit perfectly inside their Patented Breeches to Scrape out any Crud that Might Build up here, But fact is, if you Clean properly, There will be NO CRUD Build up here, I rarely ever use my TC Patented Breech Scraper Tool, the Times i have, i have got NOTHING, Which means i am Properly Cleaning, Drying, Oiling, Protecting my Barrels

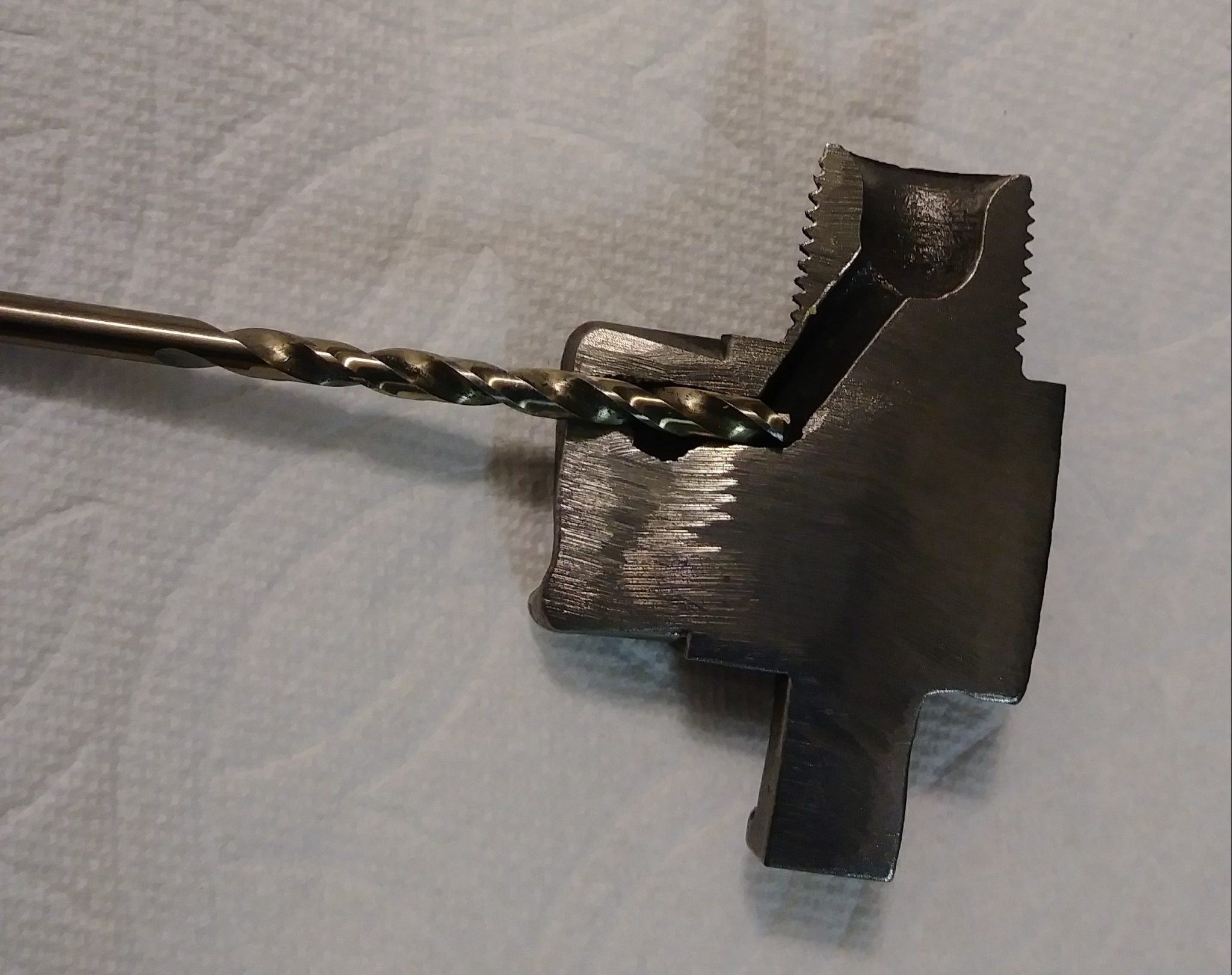

Now Here is how they made these things, They Drilled down through the Bottom of the Patented Breech/Powder Chamber at an Angle, But as you can see they were not able to Meet up under the Nipple, Pretty hard to Drill around a Corner So they went at this angle straight down to the Proper Depth to meet up with the Nipple, Then drilled across to meetup (See next Photo)

So they went at this angle straight down to the Proper Depth to meet up with the Nipple, Then drilled across to meetup (See next Photo)

Now they had to Drill Across the Breech plug, Going under the Nipple, and over to Connect with the “Fire Channel“ Hole in the photo above

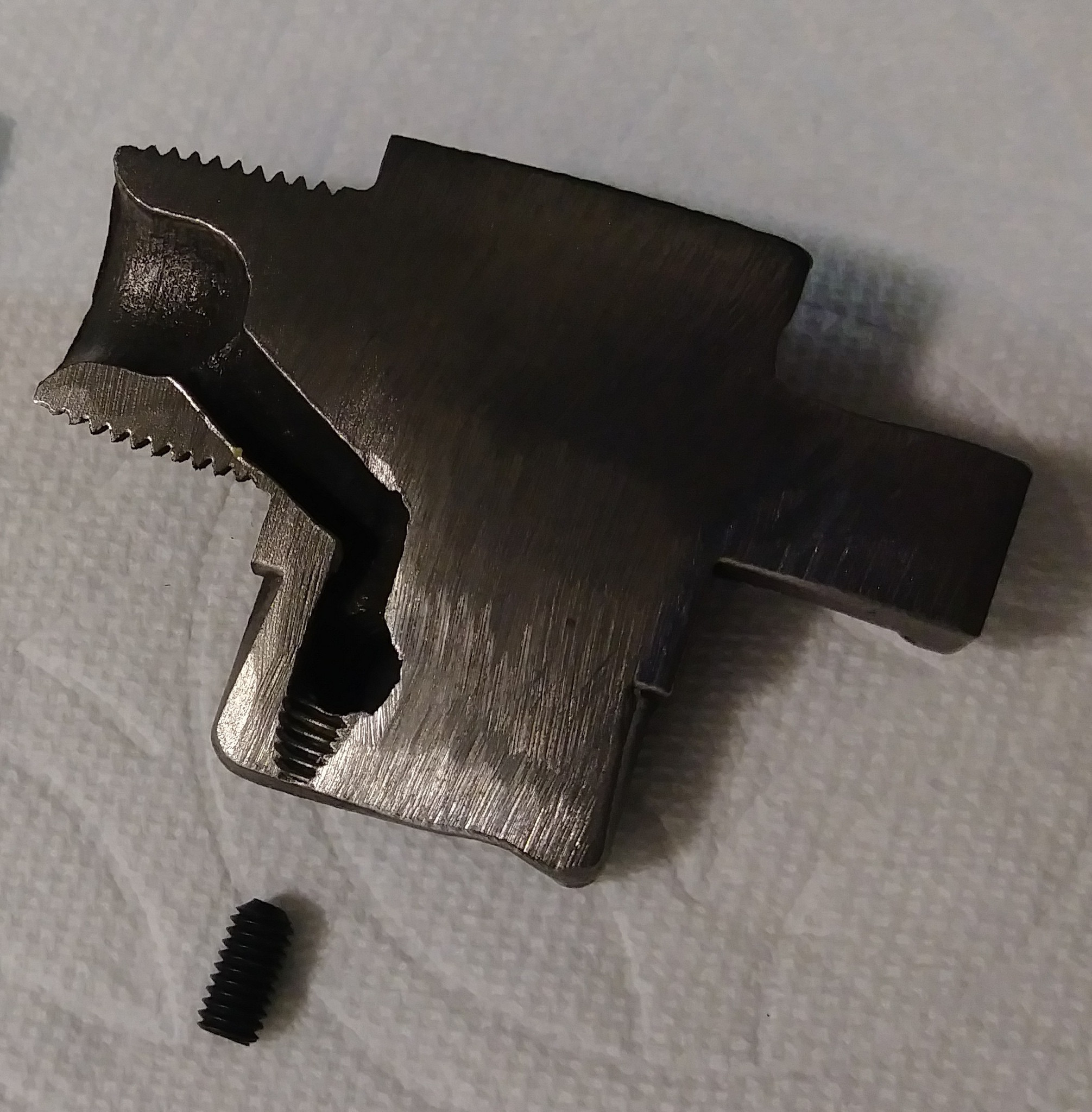

Now that they have the Holes Connected, This leaves a WIDE OPEN Hole in the Side of the Breech Plug, They had NO CHOICE But to Tap this Hole, and use a Plug to Fill it, This is where the Term “Cleanout Screw” Comes from, It is Put there because it HAD TO BE in order to Close off that Hole. Again, it is NOT NECESSARY To Remove this Screw for Cleaning, it is better left WELL ENOUGH ALONE

And another photo, this time with a Nipple in place

This TC Breech Plug has the Visible, Removable “Cleanout Screw” I Personally LEAVE THESE ALONE!, There is NO NEED to remove this Screw for Cleaning. It was put there because it HAD to be, due to the Way they were made, Obviously They HAD to Plug this Hole somehow. You will see Below

Again, If your Rifle does NOT have the Visible Cleanout Screw, Look CLOSELY on the Opposite Side and you will Spot it, Sometimes they Blend in pretty good, But you will See it

Here you can see the Cut-Away Breech plug (Right) and the Barrel piece (Left) I simply popped them Apart for this Photo tutorial

Red Arrow Pointing at the Patented Breech/Powder Chamber

TC made a “Scraper Tool“ to fit perfectly inside their Patented Breeches to Scrape out any Crud that Might Build up here, But fact is, if you Clean properly, There will be NO CRUD Build up here, I rarely ever use my TC Patented Breech Scraper Tool, the Times i have, i have got NOTHING, Which means i am Properly Cleaning, Drying, Oiling, Protecting my Barrels

Now Here is how they made these things, They Drilled down through the Bottom of the Patented Breech/Powder Chamber at an Angle, But as you can see they were not able to Meet up under the Nipple, Pretty hard to Drill around a Corner

Now they had to Drill Across the Breech plug, Going under the Nipple, and over to Connect with the “Fire Channel“ Hole in the photo above

Now that they have the Holes Connected, This leaves a WIDE OPEN Hole in the Side of the Breech Plug, They had NO CHOICE But to Tap this Hole, and use a Plug to Fill it, This is where the Term “Cleanout Screw” Comes from, It is Put there because it HAD TO BE in order to Close off that Hole. Again, it is NOT NECESSARY To Remove this Screw for Cleaning, it is better left WELL ENOUGH ALONE

And another photo, this time with a Nipple in place

Justin.44

54 Cal.

Great pics and explanation @Idaholewis

WOW!! You went through a TON of work to show this!!I pulled the Old TC Renegade Breech plug back out again,,,This is to show up close Detail of how these things were Made.

Thank you for the work and sharing.

- Joined

- Nov 16, 2009

- Messages

- 4,688

- Reaction score

- 8,571

@Idaholewis is an independently wealthy philanthropist who has dedicated his life to furthering the knowledge of the Black Arts... he fights crime and the use of bore butter in his spare time.WOW!! You went through a TON of work to show this!!

Thank you for the work and sharing.

Whiskey Tango Foxtrot,???@Idaholewis is an independently wealthy philanthropist who has dedicated his life to furthering the knowledge of the Black Arts... he fights crime and the use of bore butter in his spare time.

user 34300

54 Cal.

- Joined

- Nov 25, 2019

- Messages

- 1,742

- Reaction score

- 2,125

Great cut-a-way pictures.

I was never OK with the diagonal drilling. The diagonal hole can break out at the area indicated in the photo below. Better to make a larger diameter powder chamber that intersects with the cross ways flame hole. A larger hole is more reliable and stronger if it goes straight back.

I was never OK with the diagonal drilling. The diagonal hole can break out at the area indicated in the photo below. Better to make a larger diameter powder chamber that intersects with the cross ways flame hole. A larger hole is more reliable and stronger if it goes straight back.

Similar threads

- Replies

- 5

- Views

- 306

- Replies

- 4

- Views

- 2K

Latest posts

-

-

-

-

-

-

FOR SALE Edward Marshall/Christian Springs style rifle 62 cal flint

- Latest: Johnny Too-Tall

-

-

-