-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tiger stripping?

- Thread starter WI Smoke

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

WI Smoke said:How do some people get the nice tiger stripping in ther stocks it seems like the grain would be running length wise.

WI Smoke

I believe it is the way the wood was cut that produced the stripping, quarter sawed...

coehornboy

40 Cal.

- Joined

- Mar 24, 2005

- Messages

- 218

- Reaction score

- 1

I have heard (anecdotal info only) that in old days, they would fake tiger striping by wrapping stocks in rawhide strips and burning the rawhide, or that they would dissolve iron filings in a mild acid (like muriatic acid) and paint it on (it would darken over time...)

Anyome else ever heard of this? :v

Anyome else ever heard of this? :v

Mike Brooks

Cannon

- Joined

- Jul 19, 2005

- Messages

- 6,686

- Reaction score

- 33

God put the Tiger stripe in a tree, it makes no difference how you cut it, If it is there you'll see it.

CrackStock

69 Cal.

- Joined

- Dec 23, 2004

- Messages

- 3,017

- Reaction score

- 9

The real tiger striping comes from teh grains in the cell structure of the tree. However, some claim that makers most notably as Lehman (Leman) faked such patterns in various manners. Many Lehmans were made for the Indian trade and inexpensive decoration was supposedly desired. Burning, staining or dying are all discussed but I have not seena definitive answer. A web search should yield some methods and info on the subject.

CS

CS

Mike Brooks

Cannon

- Joined

- Jul 19, 2005

- Messages

- 6,686

- Reaction score

- 33

Fake stripes were painted on with india ink.

RedFeather

50 Cal.

- Joined

- Jan 13, 2005

- Messages

- 1,306

- Reaction score

- 42

Not sure, but I believe the striping is the result of stress to the tree. Supposedly, really good striping can be found in trees that are near stream beds and which have experienced drought. What I can't figure is how come so many guns have great striping in the stock on one side, only! This was particularly true of beech stocked Ruger 10/22's and became kind of a joke.

Anybody try feathering a plain stock with an alcohol lamp?

Anybody try feathering a plain stock with an alcohol lamp?

Stophel

75 Cal.

- Joined

- Jul 8, 2005

- Messages

- 5,963

- Reaction score

- 869

It has been determined that curl is genetic. Maple seems to have this genetic trait more than most other woods. They say that if you find one good curly maple tree, chances are good that the surrounding trees are curly too, since they are related. The curl is formed by the growth of the grain. On plain wood, the grain is straight. On curly wood, it grows in a "sine wave" of sorts. If you could pull out one individual grain, it would have lots of little curves in it.

Stresses in the tree (branches, knots, butts, etc.) will cause various types of curl/burl in any kind of tree.

Stresses in the tree (branches, knots, butts, etc.) will cause various types of curl/burl in any kind of tree.

BlackNet

40 Cal.

- Joined

- Sep 18, 2005

- Messages

- 293

- Reaction score

- 2

check this out

THE MYSTERY OF FIDDLEBACK MAPLE

Demonstrating a rare depth and dimensionality, Fiddleback Maple is one of the world's most-prized hardwoods. The Fiddleback Maple figuring is occasionally found in other hardwoods, including walnut, koa, ash and, rarely, other domestic and imported hardwoods.

Fiddleback Maple is also known as 'Flame Maple', 'Tiger Maple', 'Curly Maple', or 'Tigerstripe Maple'. Fiddleback Maple exhibits a dramatic change in the individual stripes or lines. As the incident angle of the light is slightly altered, the dark stripe becomes a light stripe, and the light stripe becomes dark. This visual phenomenon is known as 'chatoyancy' in the gemstone world, and its most dramatic form is seen in catseye chrysoberyl.

True Fiddleback figuring is not to be confused with "compression grain" or "stress grain" found where roots merge into the bole and also on the underside of large limbs. Some differentiate between Curly and Fiddleback figuring. For instance, curly cherry and curly birch can exhibit much swirls, waves and curls, though they are far more irregular and large, often appearing as flattened arches stacked one on top of another over the length of the board. Fiddleback Maple (Flame Maple, Tiger Maple) grain is generally considered to be more pronounced with tighter striping, sometimes measured as tight as several stripes per inch. Unlike many forms of curly grain, Fiddleback describes a series of tight, parallel (or nearly parallel) stripes running perpendicular to the length of the board.

In the United States, most use the terms Fiddleback Maple and Curly Maple synonymously. Fiddleback Maple boasts a three-dimensional series of alternately bright and dark stripes that shade into one another as the wood is slightly moved, thus producing an illusion of actual waves. Changes in brightness result from differential light reflection. Relatively high absorption by exposed fiber ends produces dark bands; reflection and diffraction from fiber walls cause bright bands. Because the fiber walls are curved sharply and act as concave or convex reflecting surfaces, any change in angle of view or incident light makes the apparent waves seem to shift. Again, the same light stripe becomes a dark stripe and vice-versa.

The illusion of undulations results from regular and repeated, parallel, wavy lines that produce an interference pattern on the exposed plane. Modern botany and science still cannot adequately account for what exactly causes the visually-stunning figuring in Fiddleback Maple (also known as Flame Maple, Curly Maple, Tiger Maple, Tigerstripe Maple). In conclusion, then, the cause(s) of the rare figuring seen in Fiddleback Maple is yet unknown. The mystery of Fiddleback Maple, in spite of electron microscopes and huge advances in the fields of wood technology, plant genetics, etc., for now remains unrevealed.

While the precise cause of the Mystery of Fiddleback Maple must remain, at present, unknown, the result is well-known, greatly esteemed, and eagerly sought by wood aficionados as Fiddleback Maple- one of the world's most transfixingly beautiful exotic hardwoods.

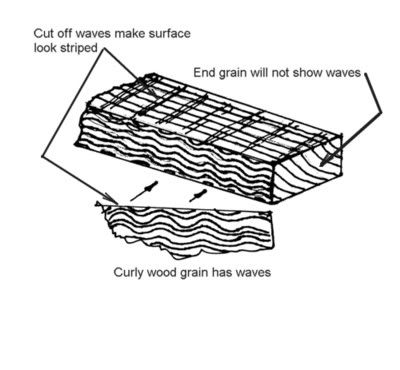

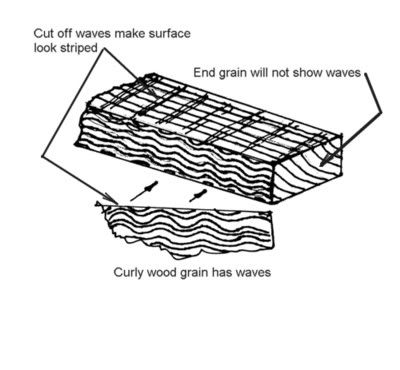

The grain is running parallel with the wrist or barrel while the stripes are verticle.

The grain of the wood waves back and forth as it goes up the tree or out the limb.

This sketch shows what I mean:

When the surface is made, it cuts off the tops of the waves leaving something that closely resembles end grain. As there will be areas where the wavey grain is running parallel with the surface, the wood looks like normal side grain.

This is what creates the stripes.

I have heard many reasons for this curl but I must believe it is genetic. I have also heard that there is no way to tell if the Maple or Ash tree has curl except to cut off a limb and split the wood along the grain. If it's a curly grain it will split with the same little wavy grain look as I show in my sketch.

The grain of the wood waves back and forth as it goes up the tree or out the limb.

This sketch shows what I mean:

When the surface is made, it cuts off the tops of the waves leaving something that closely resembles end grain. As there will be areas where the wavey grain is running parallel with the surface, the wood looks like normal side grain.

This is what creates the stripes.

I have heard many reasons for this curl but I must believe it is genetic. I have also heard that there is no way to tell if the Maple or Ash tree has curl except to cut off a limb and split the wood along the grain. If it's a curly grain it will split with the same little wavy grain look as I show in my sketch.

Hi

I'm a long time lurker / new poster. I have an originial late perc. fullstock that was painted orange and then had a dark brown paint or glaze over the orange. A tiger striped pattern was raked through the glaze/paint. It looks better than it sounds.

Bruce Robb

I'm a long time lurker / new poster. I have an originial late perc. fullstock that was painted orange and then had a dark brown paint or glaze over the orange. A tiger striped pattern was raked through the glaze/paint. It looks better than it sounds.

Bruce Robb

tnlonghunter

40 Cal.

I saw a gun a while ago, whose owner told me his father built it and made it sriped by tying a couple hundred pieces of hemp twine soaked in muratic acid around the stock and then let them sit for a month or 6 weeks before removing and finishing.

Doc Arroyo

Greybeard

- Joined

- Apr 6, 2004

- Messages

- 976

- Reaction score

- 9

I saw a striping brush in a private collection of gunsmithing tools. Picture a cheap 3" wide Chinese paint brush from Home Depot...cut the bristles to about 1/2" long. Then remove sections of bristles so it resembles a box joint. 1/4" of brush, then a 3/8" gap and repeat. Then the old smith would use some very dark pigmented stain and an unsteady hand to create false curl in cheap maple. I have seen a couple of Leman trade rifles that were possibly made with this technique.

Doc: Somewhere, I saw some drawings of the brushes Leman used to produce their stripes and it looked very much like the brush you describe.

The faux striping was almost a Leman trademark from what I've read.

The faux striping was almost a Leman trademark from what I've read.

Today, I found the article on the Leman striping method, or at least how one person who studies and builds the Leman guns makes his stripes.

In the August 2000 edition of MuzzleBlasts in the "Stump the Experts" column Jack Brooks wrote a article for the Bevel Brothers about what he uses to reproduce the stripes that Leman painted on his plain maple stocks.

Jack Brooks specializes in the Leman Rifles and one of his creations is featured on the cover of the November 1990 Issue of MuzzleBlasts.

Jack uses a 1 1/2 inch China Bristle brush by cutting the bristles down to about 3/8 inches long. He then cuts the remaining bristles so that there are 8 small groups of bristles left.

These appear to be about 1/16 in diameter in the photo provided. That would be roughly (8) 1/16 inch bristles and (7) .140 spaces.

He suggests you practice with this brush before using it on your rifle.

The author says many of the Leman guns he's studied have this 8 stripe pattern which I take to mean that there are 8 uniformly spaced stripes and then a not so uniform space where the maker repositioned the brush for the next series of stripes. Make sense?

He uses 10% Nitric Acid solution and heat to stain the stock a reddish brown and then uses the brush to paint on the stripes.

For the stripes, he uses Dark Brown Fiebing's Leather Dye and mentions there is a knack to doing this. Too much dye runs together and not enough dye leaves gaps in the stripes.

He finishes the stock with one or more coats of brushed on Varnish which he says turns the acid stained areas into "an orange butterscotch contrasted by the dark reddish brown stripes".

He also mentions that brush marks in the varnish on the originals are seen so don't be too worried if your gun ends up with these.

I guess these brush marks are to be expected. After all, Leman was known for making large numbers of good, dependable trade guns. The painted on stripes may have been the fanciest part of them. :grin:

In the August 2000 edition of MuzzleBlasts in the "Stump the Experts" column Jack Brooks wrote a article for the Bevel Brothers about what he uses to reproduce the stripes that Leman painted on his plain maple stocks.

Jack Brooks specializes in the Leman Rifles and one of his creations is featured on the cover of the November 1990 Issue of MuzzleBlasts.

Jack uses a 1 1/2 inch China Bristle brush by cutting the bristles down to about 3/8 inches long. He then cuts the remaining bristles so that there are 8 small groups of bristles left.

These appear to be about 1/16 in diameter in the photo provided. That would be roughly (8) 1/16 inch bristles and (7) .140 spaces.

He suggests you practice with this brush before using it on your rifle.

The author says many of the Leman guns he's studied have this 8 stripe pattern which I take to mean that there are 8 uniformly spaced stripes and then a not so uniform space where the maker repositioned the brush for the next series of stripes. Make sense?

He uses 10% Nitric Acid solution and heat to stain the stock a reddish brown and then uses the brush to paint on the stripes.

For the stripes, he uses Dark Brown Fiebing's Leather Dye and mentions there is a knack to doing this. Too much dye runs together and not enough dye leaves gaps in the stripes.

He finishes the stock with one or more coats of brushed on Varnish which he says turns the acid stained areas into "an orange butterscotch contrasted by the dark reddish brown stripes".

He also mentions that brush marks in the varnish on the originals are seen so don't be too worried if your gun ends up with these.

I guess these brush marks are to be expected. After all, Leman was known for making large numbers of good, dependable trade guns. The painted on stripes may have been the fanciest part of them. :grin:

pathfinderifh

40 Cal.

- Joined

- Sep 11, 2005

- Messages

- 190

- Reaction score

- 0

Damn, the secret is out! We have been using this system with slight variations for @ 150 years or more on the fake golden oak furniture. I've had some mighty surprized customers who stripped their own Golden oak furniture, only to find they had birch and maple under the "tiger oak". It was a simple matter to re-finish "back" to tiger oak using the stain and ink meathod. It was also used to simulate rosewood and some satinwood's. :winking:

Pathfinder

Pathfinder

Doc Arroyo

Greybeard

- Joined

- Apr 6, 2004

- Messages

- 976

- Reaction score

- 9

reddogge said:It' not nice to fool Mother Nature.

Ain't foolin mother nature, foolin the human eye. That's what craftmen have been doing for centuries. Take a look at Mount Vernon. It's got sand mixed into the paint covering wood to make folks think that it is stone. At least one of the "marble" fireplaces is also painted wood.

And old George never told a lie! :v

And old George never told a lie!

A hopefully interesting aside on historical fakery... I toured the Confederate Whitehouse in Richmond, VA during some slack time on a recent business trip. The main entry had "faux" marble trimmings original to the house. The guide said at the time the home was built the "faux" marble (scagliola) was the "in" thing and was more expensive than the real stuff... LOL the original columns in the Idaho State Building are also scagliola.

[url] http://www.idahocapitolcommission.org/restoration/renewalnews/rn19-121801.pdf[/url]

Last edited by a moderator:

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 9

- Views

- 1K

SOLD - Pending funds

REDUCED Nice Custom .45 Percussion Virginia Style Rifle

- Replies

- 3

- Views

- 799

Latest posts

-

-

-

-

-

-

-

FOR SALE very nice Veteran Arms 1st Land Pattern Brown Bess for sale!

- Latest: FlintlockMilitaryRifle

-