hockeyref

40 Cal.

- Joined

- Dec 16, 2008

- Messages

- 250

- Reaction score

- 44

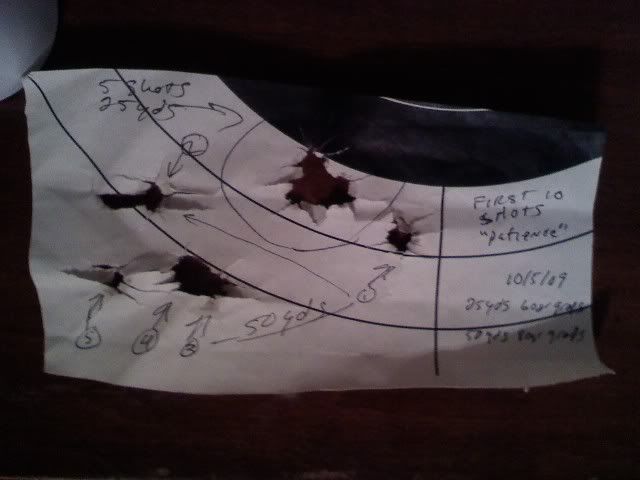

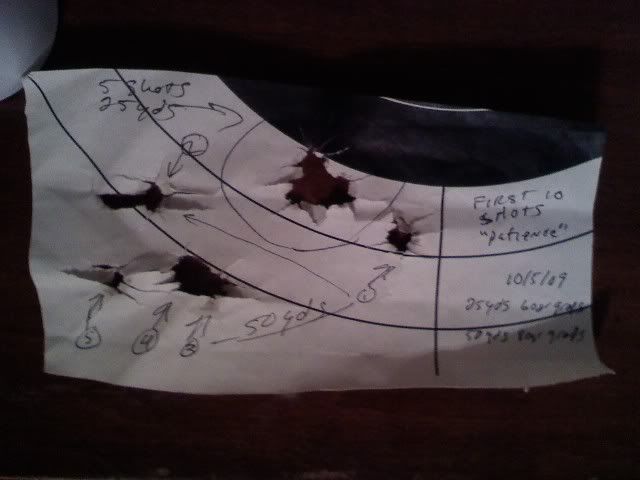

Well, I took patience out today... She's the GPR kit that I started 8 moths ago.... I'll get some pics of her up shortly, but this one will have to do for now. The first 5 shots from the bench at 25 yards. 60gr 3f Graff's, .015" precut pillow ticking, TC Bore Butter, .530" swaged ball. Thought I bought .535" balls until I got to the range and looked at the package.. I'll run 'em down range and then try some .535" balls.

First patch.... only one I found. The grass in front of the bench was high and they blended in really well. Kinda think I need to be thicker or use the larger diameter ball.

Bore seemed smooth enough after polishing the rough edges off. I punched the bore with an alcohol soaked patch followed by a dry one in between shots.

Moved back to 50 yards and upped the charge to 80gr and the POI remained about the same. got a couple pan flashes and weak sparks on this five... also did a spit patch and dry one instead of the alcohol patch from the first five. Probably more me (my eyes and poor light) than the load spreading stuff out... Will get back out in a couple days and make more smoke!

First patch.... only one I found. The grass in front of the bench was high and they blended in really well. Kinda think I need to be thicker or use the larger diameter ball.

Bore seemed smooth enough after polishing the rough edges off. I punched the bore with an alcohol soaked patch followed by a dry one in between shots.

Moved back to 50 yards and upped the charge to 80gr and the POI remained about the same. got a couple pan flashes and weak sparks on this five... also did a spit patch and dry one instead of the alcohol patch from the first five. Probably more me (my eyes and poor light) than the load spreading stuff out... Will get back out in a couple days and make more smoke!