That would be great! I'd love to know any problems you ran into on the the original build, and now that you have more experience, what you plan to change. Thank you, friend.

More than glad to give you my impressions of the Kentucky, and the Hawken.

Nothing really bad about either of them other than there was a lot, and I do mean a lot of extra wood around the butt plate and endcap....

Heheh, I even sent a couple of pictures of this to Traditions, and they were equally surprised.

Now don't get me wrong, a little extra wood is good, but mine was rather significant to me with the equipment I had on hand!

Almost 1/4" extra on the Kentucky, and I really did not have the hand tools / file set, to quickly and easily do the job at that time, so I hand sanded everything to fit!

My timing on contacting Traditions about this was quite good, as the manufacturer from Spain was in their building for a visit.

They used my photos and comments to communicate what I had found, and they are making improvements in their manufacturing based on my input.

I am going to revisit the Kentucky, as I do not like the color that the stain came out, and when I was pinning the barrel to the stock I hit the stock lightly a couple of times and you can see the dents that were left, so time to sand / file it all down again, and re-stain.

Also, keep in mind on the Kentucky, it does not have wedges that hold the barrel to the stock.

You will be required to measure carefully from the end of the barrel, and drill two #32 holes through the stock and barrel tangs to keep it in place.

I have the equipment to do that, but I would not try doing it by hand.

A drill press will do so much better for you in that area.

Even with what I had to work with, it was a little on the scary side, and I have done this type of stuff when I was working for over 40 years.

The Hawken came to me raw out of the box, with a chip in the stock.... picture below, but this picture is after I sanded and stained it.

They did offer to replace the stock, but because I had chosen already to make it old, used but loved looking, I declined.

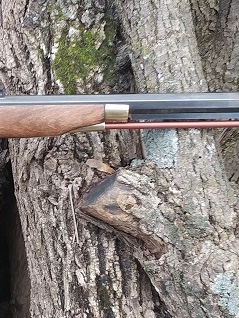

Here is the end cap on the Hawken in the raw.

Not as much extra wood as was on the Kentucky, but it will give you an idea of what I had to do to blend it into the endcap.... 99% by sand paper, heheh, I now have a woodworking file set that is going to save me, my hands and fingers quite a bit on my next build..... once I learn to control them.

Also, the sights on the Hawken were plastic!

One cracked when I leaned the rifle against my rack in the corner gently, but c'mon, plastic has it's place (that is what I worked in proudly for 40 years) but not on a rifle such as these.

They did send me an upgrade metal pair of sights for free, (I offered to actually buy them, but they said no) so if you have an issue down the road, contacting them politely with pictures really makes a difference.

They have treated me quite well so far, which is why my next build will be from Traditions.... then a Lyman is on the scope!

I am more than glad to answer more questions you may have, and if I think of anything else I will continue to post it here for you to see even though this post is about my Crockett, it is finished as far as I am concerned for the moment....

I really do not want to start another post on the forum about something I have already done, and make it seem like an only negative post about Traditions, because I truly enjoy their kits and building them.

The end cap on the Crockett is going to have to stay the way it is for now, I finally narrowed it down to the fact it came from the factory with the two screw holes in the stock already countersunk for the mounting screws in the endcap, and they are off a good .050" or more causing a gap and an angle.

I will later try to move the countersinks enough to make me, Phil Coffins, Huntschool, along with all the rest, smile..... Heheh

You are all good and helpful people, so I have to say again "appreciated", and if I have the knowledge or answer for sure, I will be around!

Next build will be here early next week, so stay tuned to that one also, I will go into details as I build it of issues, and once again ask for input.