Part of the problem is that all these things have changed over the years. My early experience with caps and nipples was back in the late 1950s. In the early 1980s, I put together a CVA DB shotgun kit, and then bought 1,000 caps ( CCI #11) from a dealer over at Friendship. I had intended to do a lot of hunting and shooting, but professional commitments changed all that. I believe I sold or traded off about 300 caps to other members in my club, and shot the rest. I still have 3-400 left. I have not taken a caliper or micrometer to those caps. I know they fit on the stainless steel nipples on my shotgun. I opened the hairlip on the skirt of the hammer, to make sure that the caps broke off and split when fired, so that they can be easily removed without needlenose pliers. I also used a grinding stone bit to thin the skirt on the inside, so that the cap could expand easily. The earliest caps we bought came from Navy arms. It was much later, during the 1970s, that I bought some Remington caps at Friendship. I liked them, but often can't find them to buy. I have shot some of the RWS caps, and they are the trouble ones on my caplock revolver, and were much tighter( smaller in diameter) then, than the CCI caps I bought to get past the problem. I used to pinch the CCI caps before putting them on the nipples of that revolver, so they would stay on during recoil.

With your current data, I can't imagine what advice I would give to percussion shooters about choosing caps-- maybe, tell them to come over to the Dark Side, and shoot FLINT! :blah: :rotf: :thumbsup:

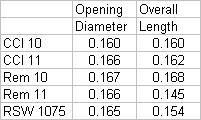

I think we are all stuck with using a micrometer to measure the necks of the nipples we buy, and then measure the diameter of the caps we think it will use. OR, take a nipple with you to test the caps before you spend your money. When I bought those 1,000 caps, they cost me less than 2 cents each.