As you can see in the photo necchi posted, removing the lock(s) won't release any hidden springs.

The most important thing in removing locks is to have a screw driver that fits the screw heads.

On a single barrel rifle/pistol the lock screws go thru the stock from the side opposite the lock.

With a double barrel, the lock screw heads are usually on one side of the gun and the screws screw into the lock on the other side.

The screws should not be too tight but occasionally they might be and you don't want to use an undersized screw driver that will mess up the screw heads.

With some guns, the trigger will move back once the lock is removed.

This makes reassembling the lock difficult because the trigger's blade ( its top surface) will be in the way of the sear arm.

It is easily dealt with by simply pushing the trigger forward and then installing the lock.

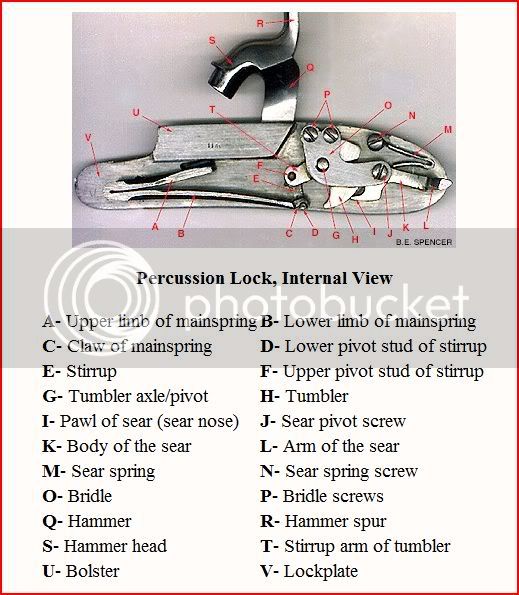

The recommendation that you check the freedom of the sear arm ("L" in the picture) and loosen the screw ("J" in the picture) slightly does not require taking the lock apart.

Of course, lubricating the moving parts doesn't require further disassemble either.