Brokennock

Cannon

Wow!

Hi,Dave,

That looks amazing! What a difference... I was looking at Brownell's and they do not have those products anymore. Do you know of anywhere else that may have similar quality products? I found this 5 pack on Amazon.

Wood Dye - Aniline Dye 5 Color Kit - Wood Stain Kit - Household Wood Stains - Amazon.com

Hi,

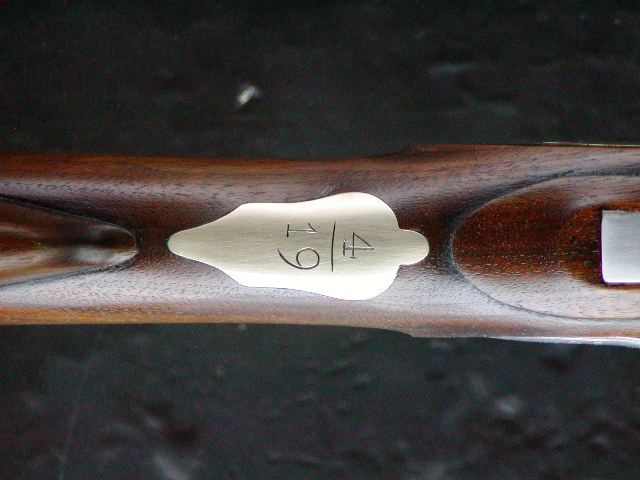

DD832, thank you for that excellent photo. It shows what I was discussing better than anything I could post.

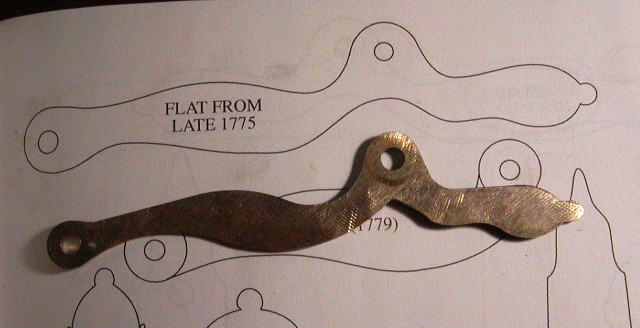

So I made a new side plate. First, I consulted Bailey's "Pattern Dates of British Small Arms" and compared the Pedersoli plate with his diagrams.

Doesn't take a genius to tell the difference between the short and emaciated Pedersoli plate and the real thing, I needed a bigger new plate that filled the space better but it had to keep the hole spacing of the Pedersoli lock. I had to lengthen the tail by 3/8" and the width of the plate but keep he same distance between the bolt holes and not have it look awkward. I took a piece of 1/16" thick brass sheet, coated it with Dykem Blue and had at it with a scribe. I like the result.

The scribed outline of the new plate really shows the difference from the Pedersoli plate.

My new plate is just 1/8" short of the the originals, which is just fine because it fills up the space much better.

dave

Enter your email address to join: