webghost

32 Cal.

- Joined

- Apr 23, 2013

- Messages

- 8

- Reaction score

- 0

Hi all,

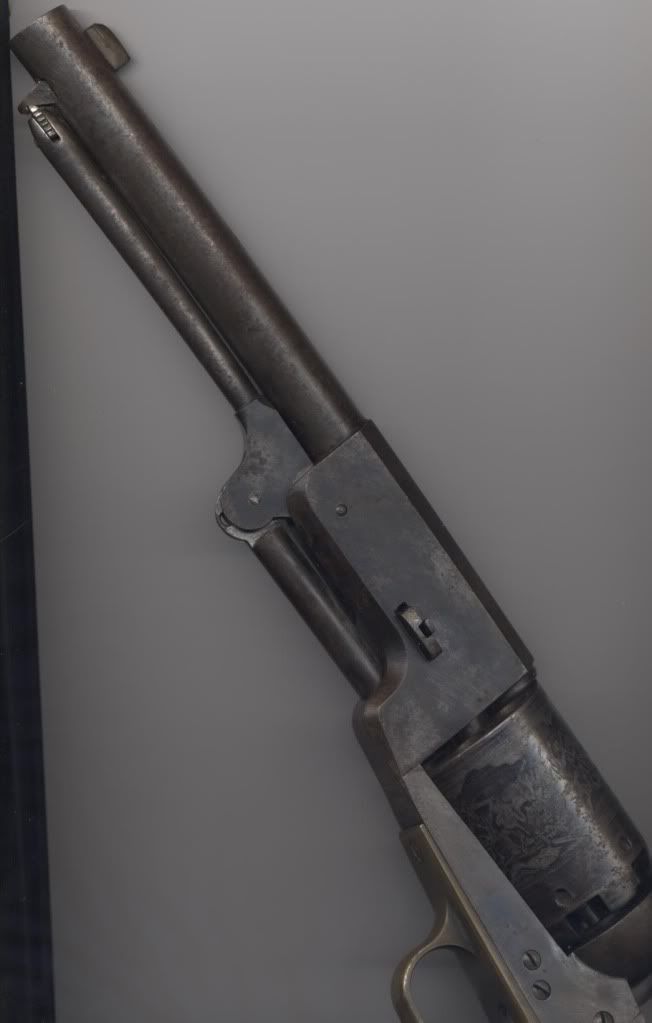

I know it is typical of most walkers where the loading lever drops based on the high intensity recoil impact of the shot. To prevent that from happening, I heard some folks mention reusable zip ties but I was curious if anyone else has devised any methods in which the loading lever can stay steady during shooting. Any thoughts/ideas would be appreciated.

Thanks

web

I know it is typical of most walkers where the loading lever drops based on the high intensity recoil impact of the shot. To prevent that from happening, I heard some folks mention reusable zip ties but I was curious if anyone else has devised any methods in which the loading lever can stay steady during shooting. Any thoughts/ideas would be appreciated.

Thanks

web