you could use cans the right size and fill with cement to the proper poundage the tube is rated for, maybeIf I were to build one I'd have to shoot real projectiles on my property. I have about 400 yds. of open ground but don't have a clue where you'd get the iron balls that big.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Well I pulled the trigger

- Thread starter Dismount

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Apr 5, 2019

- Messages

- 843

- Reaction score

- 922

Excellent. Yes.well I hhave alot of fuse but I like friction. but they are 5 bucks each so I will buy a few friction primers. so Need a 3/16'' hole

my friend at rendesvous always said, If you don't have someone cussing you, you are not a very good cannoneerWould bring new meaning for some of the neighbors for "rattle their cages" and "wake up calls"....

RM

I’m thinking I would get along with your friend.

RM

RM

The problem with the can-of-concrete projectile is

that it might not pass rough spots in the bore--

what if it jammed? You might not have to worry with

neighbors, the whole town might be lifted up !

that it might not pass rough spots in the bore--

what if it jammed? You might not have to worry with

neighbors, the whole town might be lifted up !

A couple of things:If I were to build one I'd have to shoot real projectiles on my property. I have about 400 yds. of open ground but don't have a clue where you'd get the iron balls that big.

Lead is too heavy. It’s density is 11.3 g/cm3. Iron is 7.83 g/cm3. Back in my “youth”, when I was in the N-SSA the cannon we shot was required to NOT use solid lead projectiles (balls as we had a smooth bore.). Thus we used a plaster cored lead ball. Needless to say, that wasn’t too successful, accuracy wise. Later, we started casting zinc balls, density 7.14 g/cm3. Much better. Fortunately a member of our unit worked with zinc parts and a source of zinc was obtained.

A couple of things:

Lead is too heavy. It’s density is 11.3 g/cm3. Iron is 7.83 g/cm3. Back in my “youth”, when I was in the N-SSA the cannon we shot was required to NOT use solid lead projectiles (balls as we had a smooth bore.). Thus we used a plaster cored lead ball. Needless to say, that wasn’t too successful, accuracy wise. Later, we started casting zinc balls, density 7.14 g/cm3. Much better. Fortunately a member of our unit worked with zinc parts and a source of zinc was obtained.

Figured that out through this thread. I have seen somewhere where people were using zinc.

Thanks,

RM

- Joined

- Mar 5, 2021

- Messages

- 309

- Reaction score

- 480

Awesome! Congratulations!

Way back when (1961-62), I was a member of "The Landing Party From the USS Constellation" at target shoots and Manassas re-enactment. We had a section of a 3" naval gun for which a breech plug and a Naval carriage had been made. It generally used a pound of powder to fire a concrete-filled beer can (the cans at the time were steel, not aluminum). At one of the events, I believe it was at Camp A. P. Hill, we managed to hit a sheet of plywood at 1,000 yards. Although my mind recalls a very short 1,000 yards - more like 500 yards! It was fun to shoot, I held the position of sponger. The target matches, shot with original Springfield 58 caliber weapons, were more fun - trying to shoot those clay pigeons taped to a sheet of plywood.I looked at the website for the offering of tubes and I'd probably go with the U.S carronade in full or 3/4 size and obvious from my avatar on a naval carriage harder to move around for sure but just image myself saying"fire as she bears" when I would light it off..

Jay

36 Cl.

Congratulations there’s just something about owning a canon leads to such great stories good luck

Crow-Feather

32 Cal.

Beer cans filled with cementIf I were to build one I'd have to shoot real projectiles on my property. I have about 400 yds. of open ground but don't have a clue where you'd get the iron balls that big.

sportster73hp

50 Cal.

- Joined

- Jan 16, 2020

- Messages

- 1,083

- Reaction score

- 866

What about a can of soup or soda? Not sure an aluminum can would survive, but a steel soup or beans might.

Treestalker

Treestalker

- Joined

- Mar 24, 2014

- Messages

- 4,051

- Reaction score

- 3,748

- Location

- Third Pond from the Great God Helios

Lead being so heavy, the size of bore for lead ball use usually ends at about 2". A homegrown quick match can be made by smearing a pipe cleaner in Elmer's glue and rolling it in 4f or 3f powder. Prick the charge through the touchhole and insert the quick match. Fire the quick match with a linstock for instant ignition.I know nothing about cannons, so this may be a stupid question, what about lead (wheel weights and such)?

I shot lead balls out of my 1.5" cannon at the range

My aim height was off so the lead 1.5" ball cleared all the berms and was knocking down small trees in the woods

I will never do a cannon at a range again

I also tried 1 .5" steel shaft cut to various lengths up to 2" in length, these were drops from a machine shop

lead balls and steel shot I could launch out of sight using binoculars to watch the splash in the ocean

With lots of powder and loaded that way, the cannon recoil was mighty dangerous

to keep the barrel in place when out of the truck it was normally in, I set the rear of the cannon against a pressure treated hardwood telephone pole , after one shot it left a 1\8" impression in the pole

I couldn't have hit the pole with a sleeve hammer and left a mark that deep

just saying

My aim height was off so the lead 1.5" ball cleared all the berms and was knocking down small trees in the woods

I will never do a cannon at a range again

I also tried 1 .5" steel shaft cut to various lengths up to 2" in length, these were drops from a machine shop

lead balls and steel shot I could launch out of sight using binoculars to watch the splash in the ocean

With lots of powder and loaded that way, the cannon recoil was mighty dangerous

to keep the barrel in place when out of the truck it was normally in, I set the rear of the cannon against a pressure treated hardwood telephone pole , after one shot it left a 1\8" impression in the pole

I couldn't have hit the pole with a sleeve hammer and left a mark that deep

just saying

- Joined

- Mar 7, 2007

- Messages

- 732

- Reaction score

- 2,372

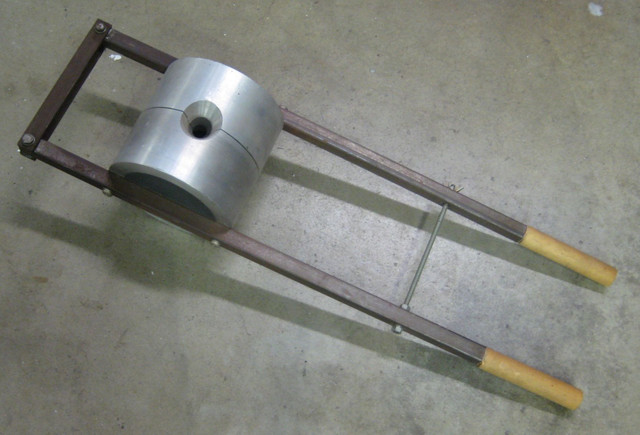

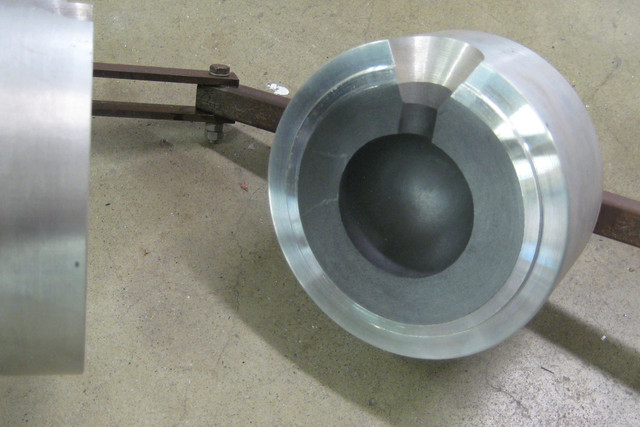

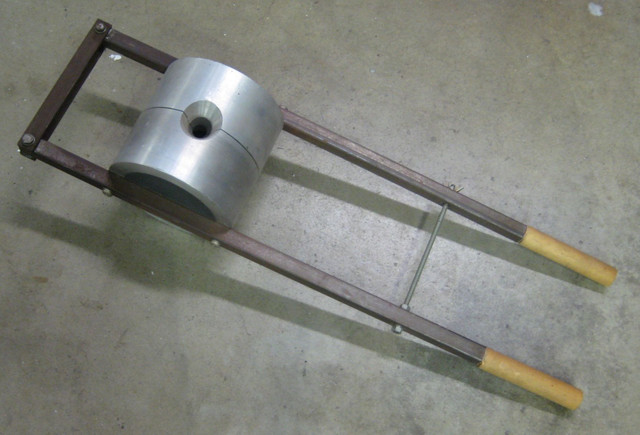

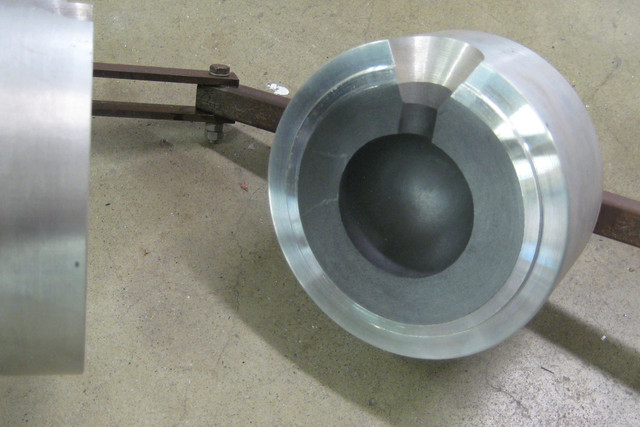

I needed a source of 2.75 inch cannon balls for one of my "larger" bore firearms. Iron is excellent, but hard to make and expensive to shoot. Zinc is a good replacement, but it isn't easy to find a good mold in that size range. So I made this one out of some heavy wall aluminum tube I had in the shop and heat shrunk the two aluminum mold shells around some graphite bar stock. The mold cavity was then cut in the blocks with a form tool. This is the first cast of the evening, so the ball is a little wrinkly. As the mold heats up, the casts have a perfectly smooth surface and are very bright, just like casting lead round ball. The only draw back is that to cast 100 rounds takes all day, a hack saw to cut the sprues off, and 300 pounds of zinc ingot !

That is craftsmanship

No that's a work of art

Beautiful

No that's a work of art

Beautiful

- Joined

- Mar 7, 2007

- Messages

- 732

- Reaction score

- 2,372

Cast Cannon balls:

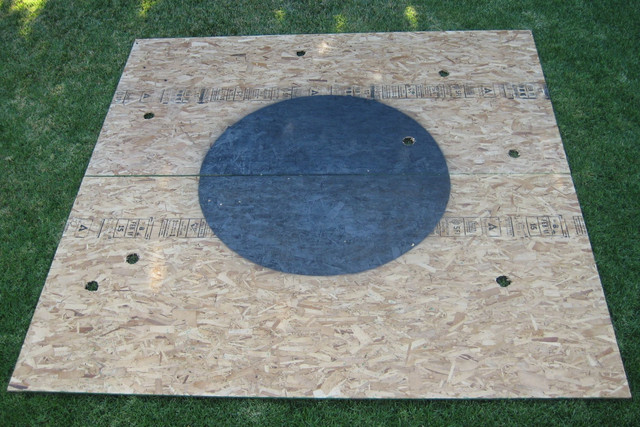

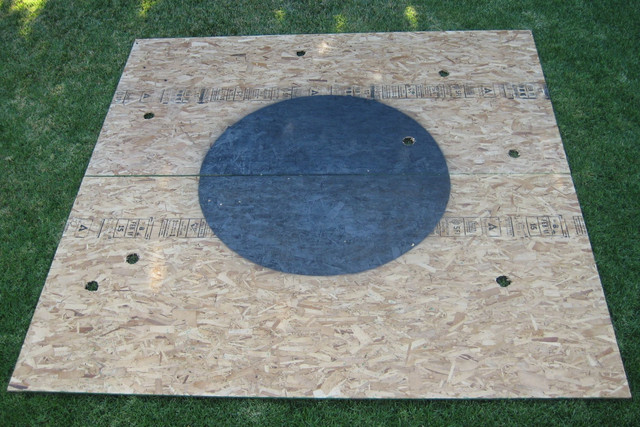

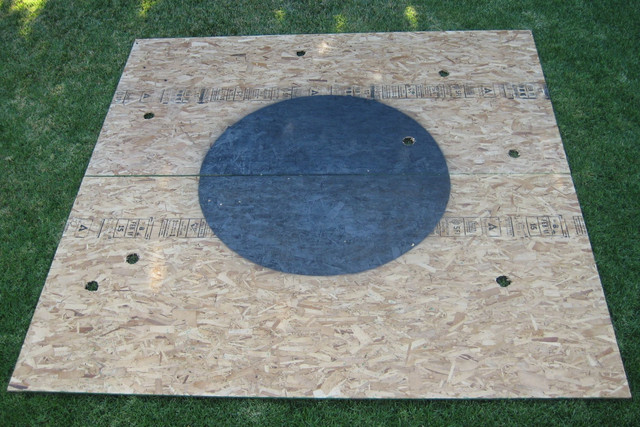

Get the gun to the range and set it up:

The gun in action......

Out of the first 12 rounds fired at a 250 yard target (48 inch black) 8 hit the target and four were near misses (one hit was on a bounce from a shot that was short). The cast ball has way too much windage and I am modifying the ball mold to get a much better fit. We should be able to keep all the rounds in a 4 foot bull at this range.

Get the gun to the range and set it up:

The gun in action......

Out of the first 12 rounds fired at a 250 yard target (48 inch black) 8 hit the target and four were near misses (one hit was on a bounce from a shot that was short). The cast ball has way too much windage and I am modifying the ball mold to get a much better fit. We should be able to keep all the rounds in a 4 foot bull at this range.

sportster73hp

50 Cal.

- Joined

- Jan 16, 2020

- Messages

- 1,083

- Reaction score

- 866

Do you recover any balls? These are a lot more work to make than for any rifle. What is the final weight?Cast Cannon balls:

Get the gun to the range and set it up:

The gun in action......

Out of the first 12 rounds fired at a 250 yard target (48 inch black) 8 hit the target and four were near misses (one hit was on a bounce from a shot that was short). The cast ball has way too much windage and I am modifying the ball mold to get a much better fit. We should be able to keep all the rounds in a 4 foot bull at this range.

But it won't fire on Sundays.one of the most feared artillery peices

Too easy to distort aluminum cans when filling them. Even when getting the top off.What about a can of soup or soda? Not sure an aluminum can would survive, but a steel soup or beans might.

Similar threads

- Replies

- 15

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

-

FOR SALE Pedersoli Tryon 54 cal. Nice condition-Personal Rifle

- Latest: #BPBReloadingFFL

-

-