-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is the maximum clyinder gap for a percussion revolver?

- Thread starter DNS

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cylinder gap should not be more than approximately the thickness of a matchbook cover.

Might vary if gun is a brass frame which has stretched from shooting, and/or has an uneven cylinder face.

Might vary if gun is a brass frame which has stretched from shooting, and/or has an uneven cylinder face.

Dave Rosenthal

70 Cal.

- Joined

- Nov 24, 2006

- Messages

- 4,470

- Reaction score

- 24

I must say that after shooting thousands of balls through my revolvers, I don't consider any of them to be "worn" to the point of being too loose or have too wide of a gap between the chamber mouths and the forcing cone. My Walker hardly has a gap at all. This fact may in fact help to make this specimen one of the most accurate revolvers on the line during league competitions. One less variable to have to deal with: a changing cylinder gap and the resulting drop in pressure and the increase in sdv.

You never did mention whether it was a Colt or a Remmy reproduction.

Dave

You never did mention whether it was a Colt or a Remmy reproduction.

Dave

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 15

I'll bet its a Colt and he dosen't know that he can decrease the gap with the wedge. :hmm:

It is a colt style brass frame from the late 60's or early 70's. Its called the Reb by navy arms. It was my first gun. It's had far to many rounds through it to count, and the gap is less than a match book cover. I bought it new, and was looking at it the other day and wondered what the gap was supposed to be. None of my steel frames have any noticable gap when the wedge is in place. It's what you do when you get old. Thanks

curator

45 Cal.

- Joined

- Dec 28, 2004

- Messages

- 685

- Reaction score

- 126

For target shooting I set my Colt-type revolver cylinder gap at .005" to .006". If you don't like to clean the cylinder face with each loading you'll get less cylinder drag by setting the gap at .008. At .010 I start to see both accuracy and velocity drop off. I use automobile "feeler gauges" to measure the gap. Cylinder/barrel clearance is difficult to set and maintain if the wedge becomes battered.

Dave Rosenthal

70 Cal.

- Joined

- Nov 24, 2006

- Messages

- 4,470

- Reaction score

- 24

curator said:For target shooting I set my Colt-type revolver cylinder gap at .005" to .006". If you don't like to clean the cylinder face with each loading you'll get less cylinder drag by setting the gap at .008. At .010 I start to see both accuracy and velocity drop off. I use automobile "feeler gauges" to measure the gap. Cylinder/barrel clearance is difficult to set and maintain if the wedge becomes battered.

Now I know what to do with my old set of feeler gauges...forgot I even had them...or which tool box their in! :idunno: :rotf:

Used to set points & plugs on my 232 c.i. straight six in my '71 AMC Hornet :haha: :redface:

Dave

The wedge not only sets the cylinder gap but affects where the barrel actually points. Using a feeler gage to set the gap is the only way to maintain consistent elevation. I go for .005" but whatever you use it should be the same every time.

Dave Rosenthal

70 Cal.

- Joined

- Nov 24, 2006

- Messages

- 4,470

- Reaction score

- 24

I guess that I must just be lucky or A-R when it comes to the gap for my Walker. I just push the wedge in till it's really snug and then use the set-screw...I assume that it goes to the same depth because it looks the same to the naked eye. I set the tolerance as close as I can without a feeler gauge or having anything rubbing or hanging-up as the cylinder turns, and so far it seems to have worked extremely well: consistently tight groups resulting in scores that win competitions in two black powder clubs.

Now that you've told me what to do and to use, I will measure the gap both before I shoot it and after I clean the gun the next time so that I may be fully aware of what said gap currently is and therefore be able to take notice of any change. Again, thanks for the advice, and I'll be sure to pass it along to the members of the clubs that I belong to.

Thanks again and Merry Christmas!

Dave

Now that you've told me what to do and to use, I will measure the gap both before I shoot it and after I clean the gun the next time so that I may be fully aware of what said gap currently is and therefore be able to take notice of any change. Again, thanks for the advice, and I'll be sure to pass it along to the members of the clubs that I belong to.

Thanks again and Merry Christmas!

Dave

I'm not sure what exactly you mean by saying you, "...use the set-screw."

Hopefully you are using it like it was intended to be used.

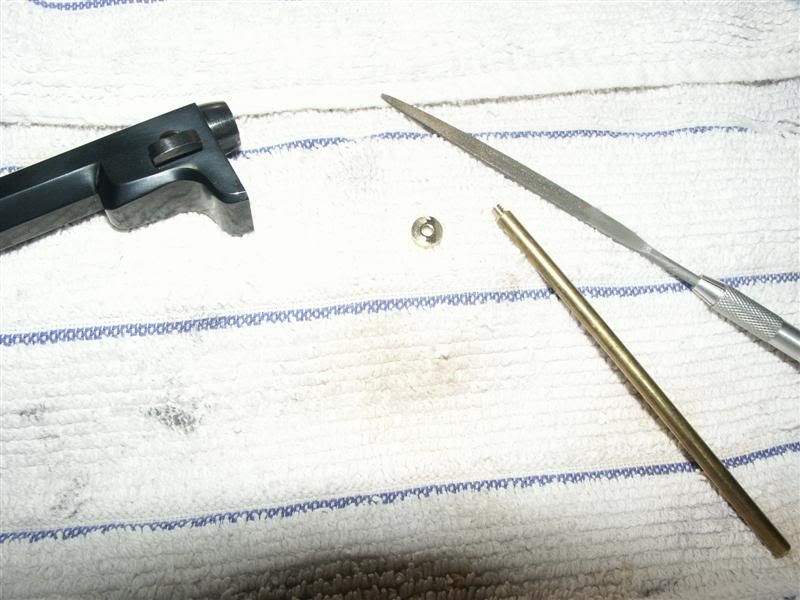

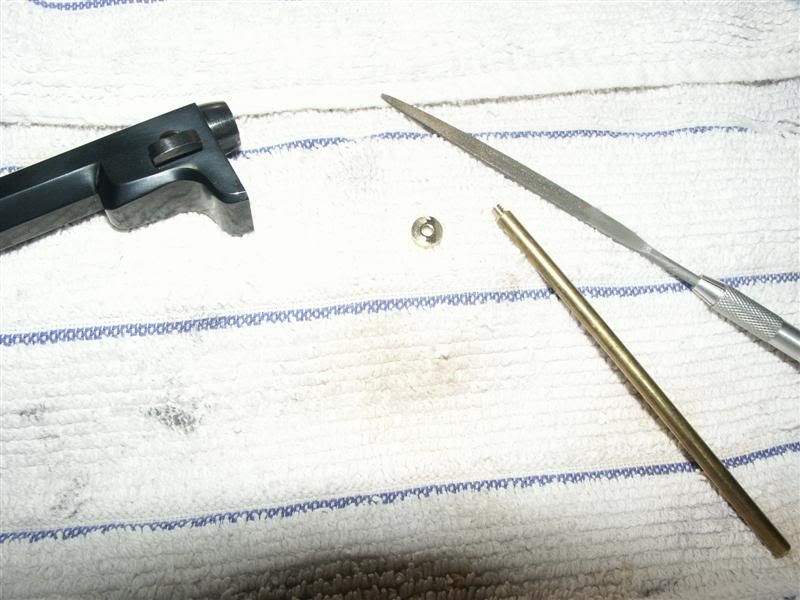

That little fillister head screw that is in the groove on the barrel wedge is meant to serve as a wedge stop.

To use it you adjust the wedge to get the proper cylinder/barrel clearance and then screw it out until it stops on the barrel wedge.

The next time you disassemble the barrel/wedge from the cylinder pin and then reassemble it you should drive the wedge in until it stops on the screw head. That will automatically set the wedge to the proper depth so that the barrel/cylinder gap is the same as it was before you took the gun apart.

Hopefully you are using it like it was intended to be used.

That little fillister head screw that is in the groove on the barrel wedge is meant to serve as a wedge stop.

To use it you adjust the wedge to get the proper cylinder/barrel clearance and then screw it out until it stops on the barrel wedge.

The next time you disassemble the barrel/wedge from the cylinder pin and then reassemble it you should drive the wedge in until it stops on the screw head. That will automatically set the wedge to the proper depth so that the barrel/cylinder gap is the same as it was before you took the gun apart.

Dave Rosenthal

70 Cal.

- Joined

- Nov 24, 2006

- Messages

- 4,470

- Reaction score

- 24

Zonie said:I'm not sure what exactly you mean by saying you, "...use the set-screw."

Hopefully you are using it like it was intended to be used.

That little fillister head screw that is in the groove on the barrel wedge is meant to serve as a wedge stop.

To use it you adjust the wedge to get the proper cylinder/barrel clearance and then screw it out until it stops on the barrel wedge.

The next time you disassemble the barrel/wedge from the cylinder pin and then reassemble it you should drive the wedge in until it stops on the screw head. That will automatically set the wedge to the proper depth so that the barrel/cylinder gap is the same as it was before you took the gun apart.

Hi Zonie!

The screw that goes into the slot in the wedge is the first thing that I take off of the gun prior to cleaning. Then I pop the wedge out of its slot. Washing the entire barrel assembly in my kitchen sink gets water everywhere, so to avoid rust I disassemble the gun and re-oil that screw every time I clean the thing. So I guess that I've never used the screw for it's intended purpose? For the loading lever I wipe it with Bore Shine and then oil it (and it's screw) as well.

Just noticed something as I have my Walker at the computer as I type this...the cylinder is moving slightly forward when the revolver goes into battery at full-cock. This removes any visible cylinder gap against the lighted computer screen. Then I just pulled on the cylinder and the gap reappears--but not much of one at all.

Oh well--it still shoots real good!

Merry Christmas!

Dave

madcratebuilder

40 Cal.

- Joined

- Jul 29, 2008

- Messages

- 208

- Reaction score

- 2

The old Colt spec was .008 gap. If you go much tighter than that you may have some cylinder binding as you accumulate fouling. I have oldies that are .015-.018, I get a little extra flame out the gap.

If your closing the barrel gap by inserting the wedge further, IMHO your arbor is to short. The arbor should bottom out the barrel lug just as the lug touches the frame and gives you the correct barrel gap. You well seldom find a revolver nib in this condition. I machine a spacer that I use in the barrel lug hole. Since I have been doing this I have zero wedge issues and accuracy has increased. I make the spacer diameter about .001 oversize and press it in the barrel lug hole.

If your closing the barrel gap by inserting the wedge further, IMHO your arbor is to short. The arbor should bottom out the barrel lug just as the lug touches the frame and gives you the correct barrel gap. You well seldom find a revolver nib in this condition. I machine a spacer that I use in the barrel lug hole. Since I have been doing this I have zero wedge issues and accuracy has increased. I make the spacer diameter about .001 oversize and press it in the barrel lug hole.

Similar threads

- Replies

- 6

- Views

- 387

- Replies

- 8

- Views

- 613

- Replies

- 2

- Views

- 572