- Joined

- Mar 7, 2007

- Messages

- 730

- Reaction score

- 2,367

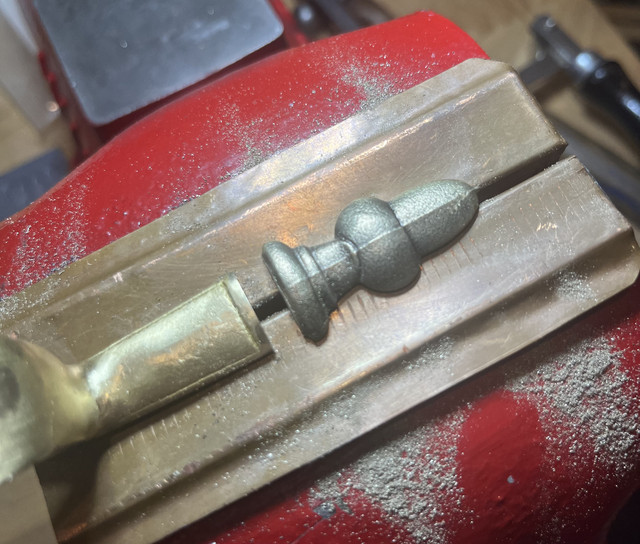

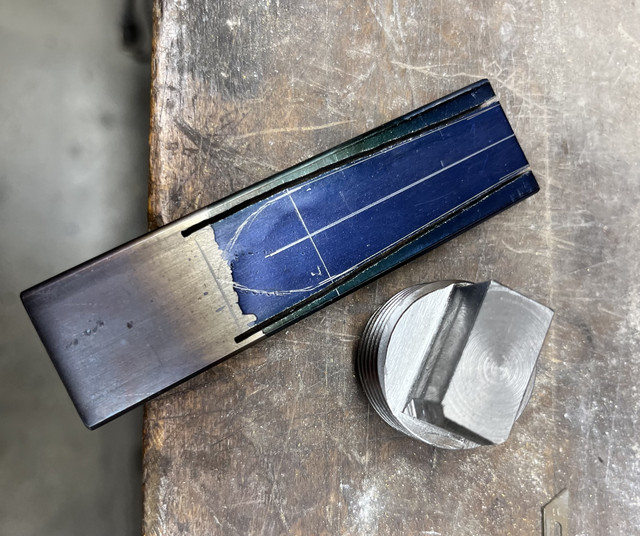

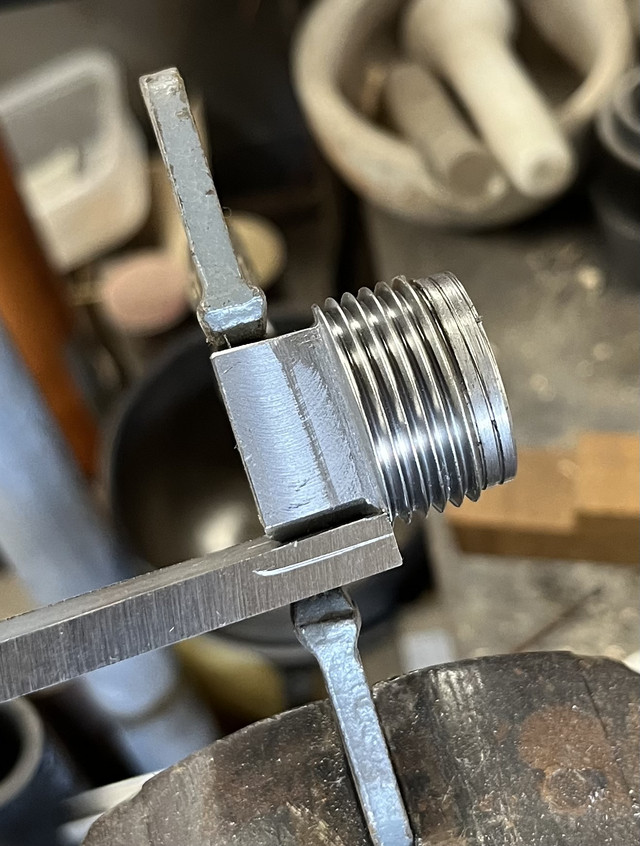

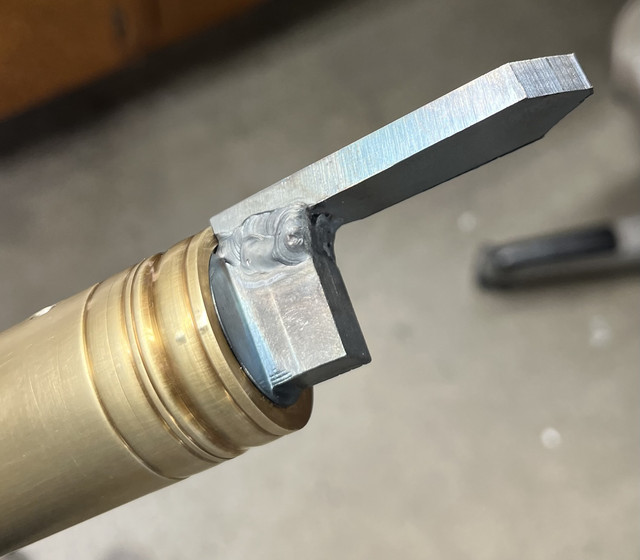

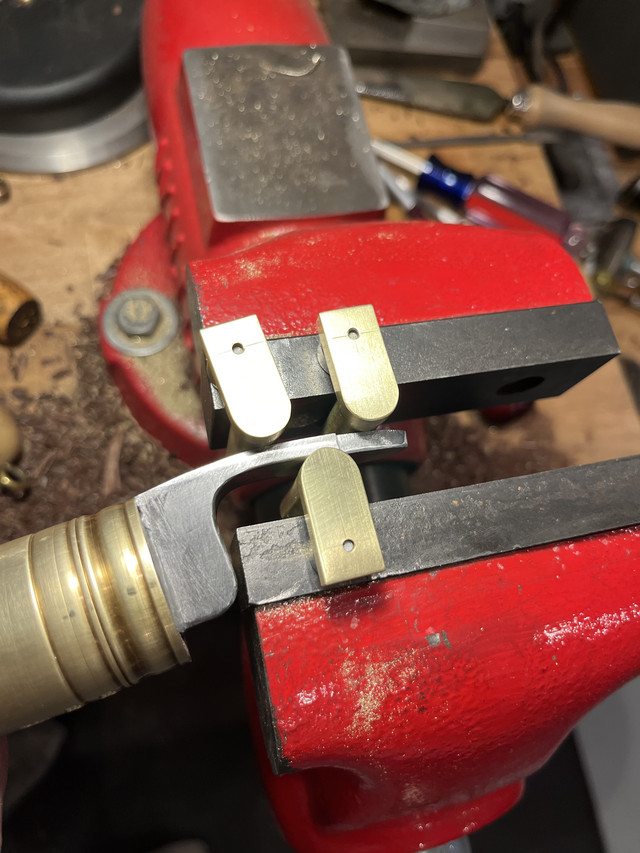

Ran the proof test today. First proof was 473 grains of 1F powder, 315 grains for the second test. Both pushed 2,100 grains (~5 oz) of lead shot. I set it off electrically each time. Just to give you a feel for how large the charge and shot column were, on the first test they took up 7 inches of a 12 inch barrel. The second proof charge took up 6 inches. Here is the set up and the video of the test......This is the same video just cropped so you can see it better. And then a picture of the post test inspection. All the original barrel diameters were the same both before and after the test.