Hi,

More work done. The lock is in and functioning properly.

All of the cast in markings on the lock plate have to be removed and correct engraved marks added. The TRS lock has markings from the carbine pattern for 1799 and appropriate for wars against Napoleon not the American War for Independence. I also inlet the trigger plate and installed the tang bolt.

Note the slot in the plate is offset to the right bringing the trigger bar closer to the lock plate. The partial machine mortise was a little off center but not enough to really matter.

I inlet the ramrod pipes. They went in nicely and the tang of the rear pipe just needs to be filed flush with the stock.

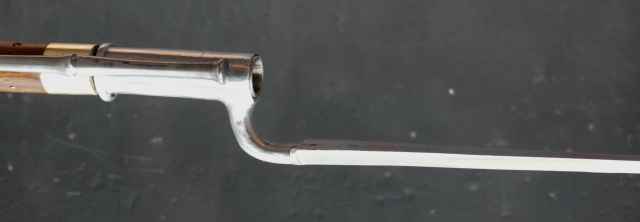

Normally, installing ramrod pipes is a trivial task but not on the Elliot and Royal Forester's carbines. The steel ramrod has a swell and cannelure (groove) that catches behind a lip on the front of the nose cap. Here is a photo of an original showing the ramrod and groove. The purpose was to make sure the ramrod did not fall out while the dragoon was bouncing along on horse back.

The TRS stock had a machined ramrod channel way too shallow for that system to work. The web of wood was too thick to allow the rod to butt up under the nose cap. I had to deepen it a lot. That presented me with a problem. I drilled the forward barrel pin hole nicely in the forward lug but not realizing how much deeper the ramrod groove had to go to make the catch system work. When I deepened the groove properly there was too little wood under the forward barrel pin to give it much strength. So I installed a new barrel lug and filled the hole I drilled. It will disappear when I am done. Then I drilled a new barrel pin hole higher up in the stock. I discovered that the position of all of the pipes effects how securely the locking mechanism works. It is not just a function of the front trumpet pipe. Every pipe has to work together to force the cannelure into the lip of the nose cap. It was very fiddley and required multiple adjustments in the depth of the pipes to get right, but I did.

More to come.

dave