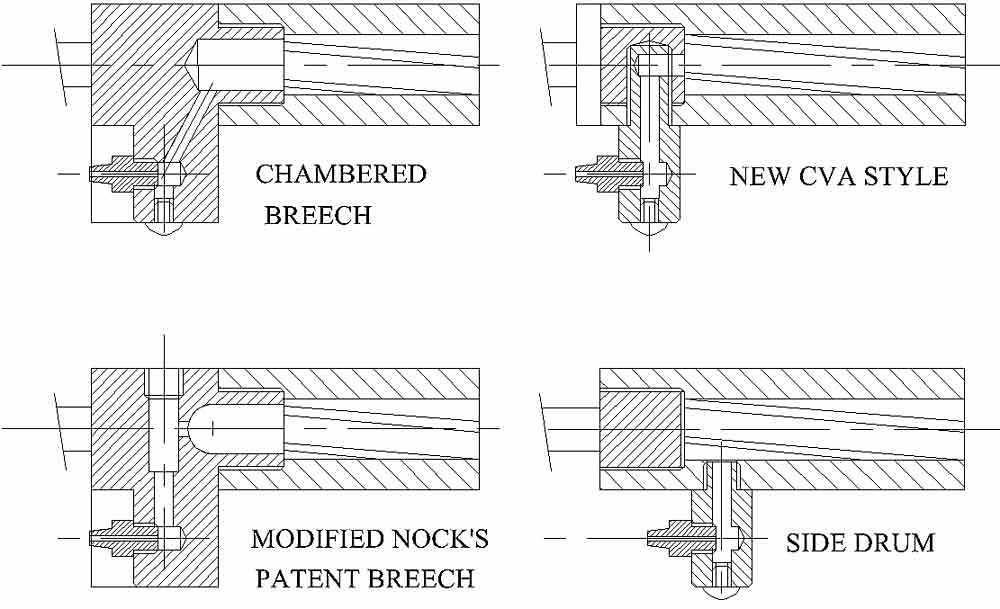

Not a Patent breech, good to know.

Clean out screw. Already pulled it and ran a Q-tip into the breech to check for anything abnormal. Thats where I found all the gunk.

Comressed air- that's the plan, I have a compressor and a nozzle that has a rubber tip. I should be able to get a good seal with it by using the hole from the cleanout screw.

Cross threaded breach: I have no intention of removing the drum or the breachplug, that is beyond my capability given the meager tools I have. Besides, with what I have read on this forum and elsewhere about these things, Im not thinking that is a place I want to go even if I had the tools to do it.

Bridle and fly lock: I'm not too concerned, the lock it has works just fine, no need to replace it. I just have to remember to squeeze the trigger all the way back and NOT let up till it fires. Which given the mechanics of shooting is second nature anyhow.

Something I didn't do: blow air through the cleanout screw hole, the nipple itself might have been plugged,

I pulled the nipple and ran my nipple pick in it to clear it but didn't try the blow test again. I noticed when I inspected it it has a TINY flash hole, and the top of the nipple is cross drilled so there are two little holes opposing each other on the sides of the nipple about where the skirt of a cap will just cover them. IF the nippples I bought for my rifle have the same threads I'm replacing this one anyhow as I have a spare new one for the rifle.