Well, work afforded me the opportunity to work the lock on the kit today :grin:

Included with the kit is a wonderful Jim Chambers early Virginia lock. If you have experience with chambers locks you are aware they are top notch. That said, they are however far from finished. While functional out of the box, much time can be spent refining cast marks, mold lines and various nooks and crevices on every part of the lock.

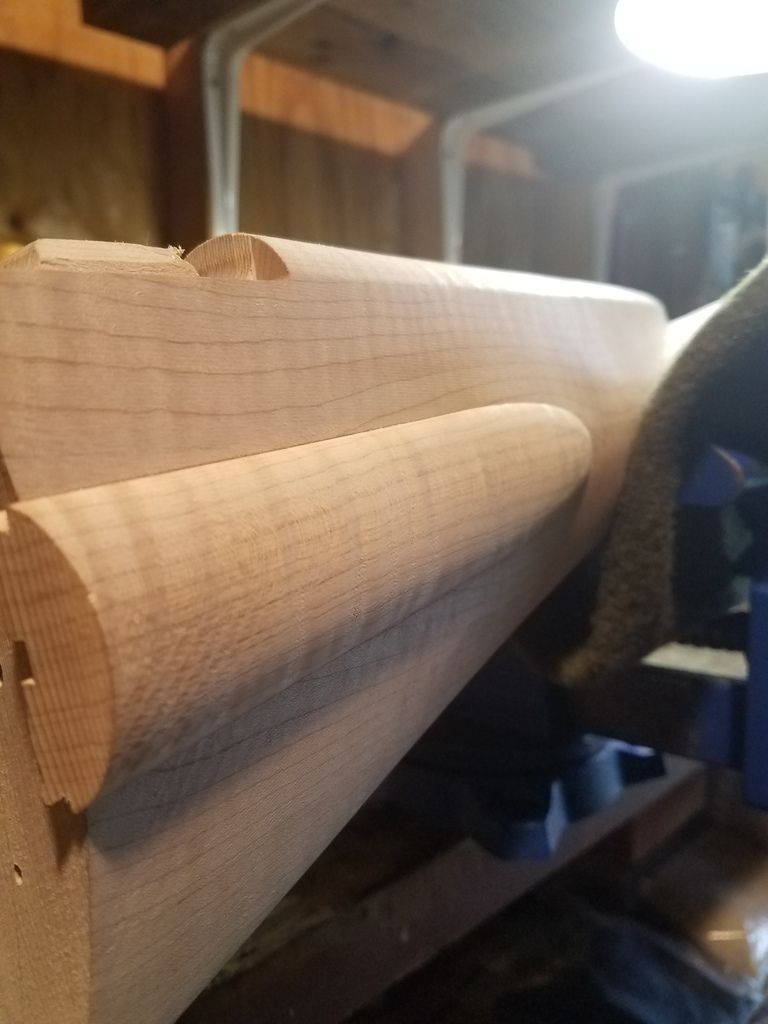

Particularly the greatest amount of work will be done on the lock plate itself including filing in a slight draft. While each lock will vary being a cast piece my particular lock had a great deal of cast lines and mold marks all over. While again one can certainly choose not to do these steps, it indeed is all about the details!

I spent five hours total from start to finish working each piece with files and varrying grits of paper down to 1500 grit. One can expect similar work to be done, nothing hard just tedious work that takes time and a good eye. Once completed I personally like to go over every piece with red scotch brite. To wrap it up, every contact and bearing surface has been touched up, all parting lines and nastys left over from casting are removed yielding a smooth and graceful lock. Again, to finish the lock correctly one should certainly do the same, as... the details matter!

Lastly I plan to apply a rubbed back finish once the lock is completely inlet into the stock. One can finish as desired!

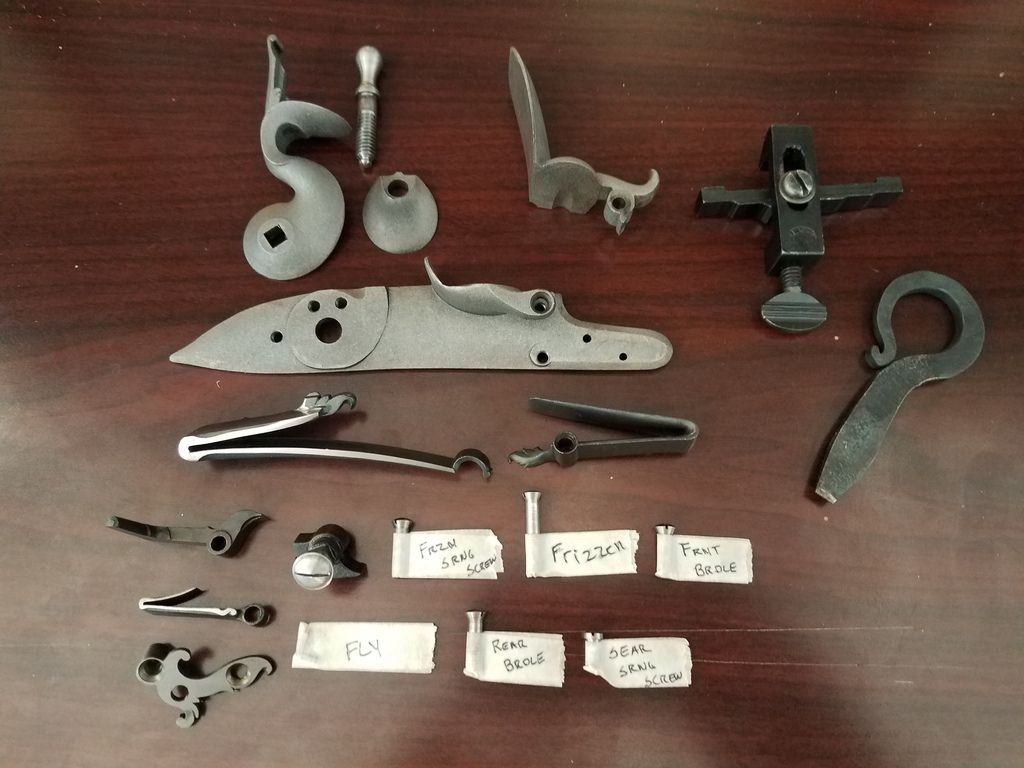

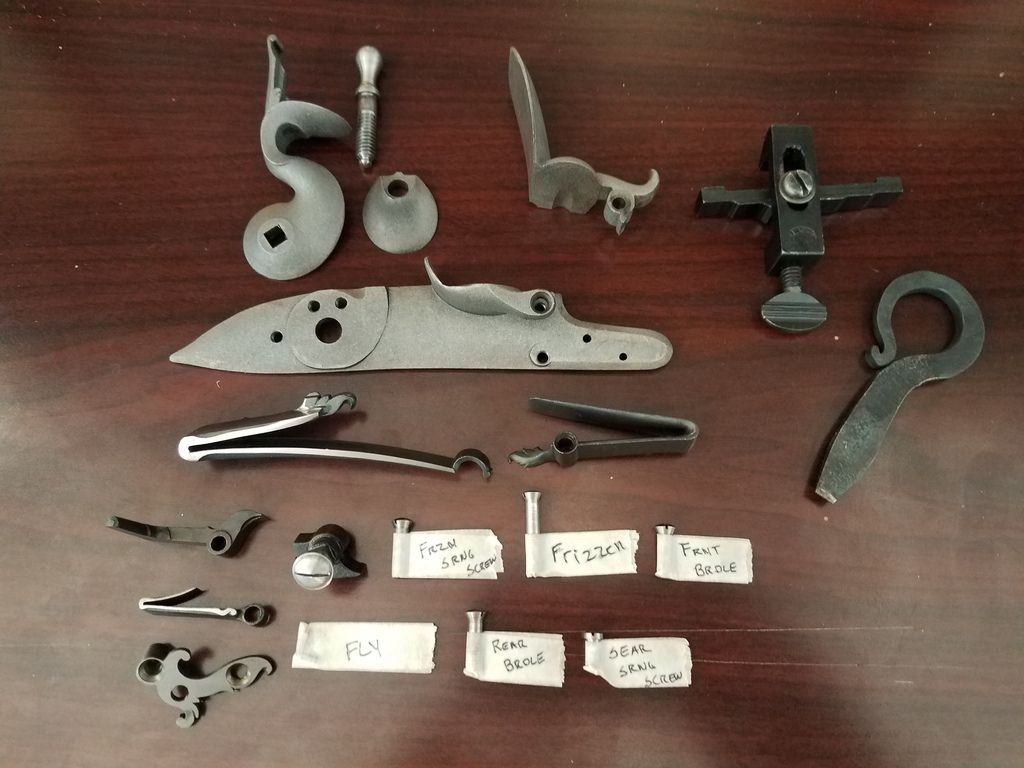

Lock before work began, you'll notice the mainspring vice. If you do not have one by all means purchase one. I under no circumstance recommend using pliers or vice grips to remove the spring. Everyone can do as they wish, but the risk is not worth it IMO.

Work completed on respective parts, ready for a finish.

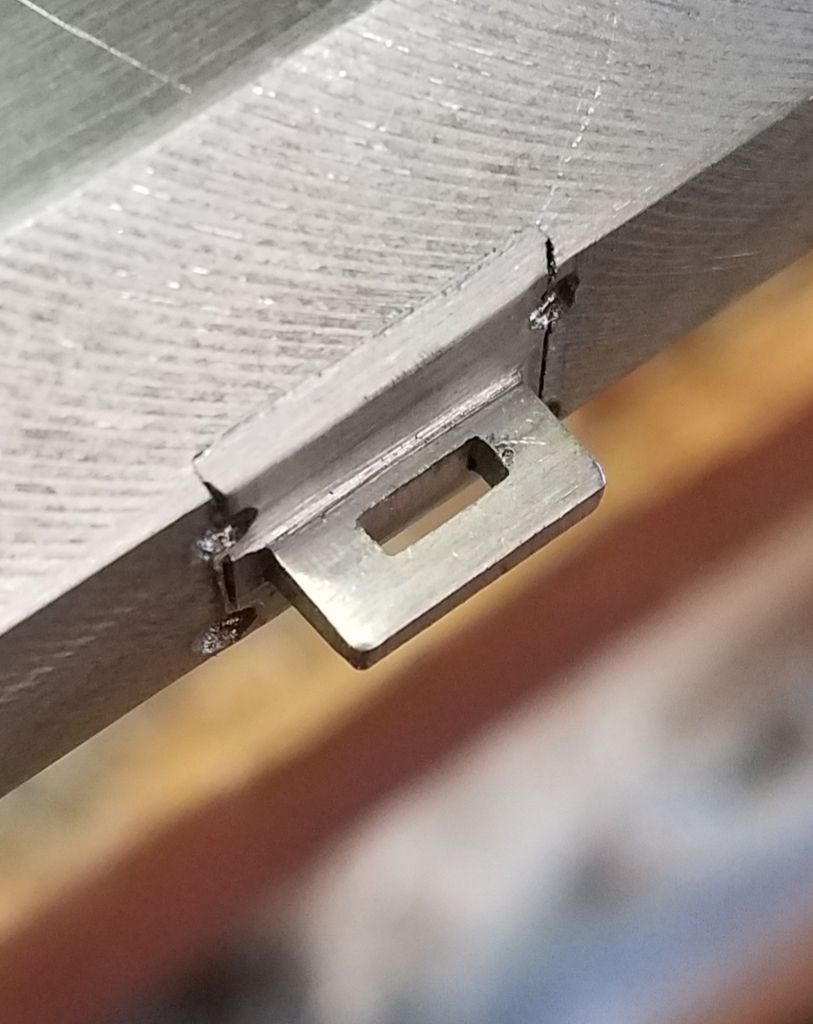

I like to polish my pans, all by hand down to 1500grit. The contact surface of the lock plate receives the same treatment which requires very little work. Some imperfections existed, nothing major at all.

Time was spent shaping the "heart" atop the frizzen. Again, just the little details that ultimately make your finished piece stand out. Frizzen in general took a fare amount of filing.

The cock required a good amount of work, profiled the edges and removed parting lines and crusty pieces left from casting.

Lastly I finished up my work by using a triangle file on all the screw heads on the lock giving them the V profile found on original handmade screws.

Much more to go! :hatsoff: