mahkagari

40 Cal.

- Joined

- Jun 18, 2015

- Messages

- 226

- Reaction score

- 63

This is as much to get things straight in my head as let y'all ID any gaps in my process.

My ultimate goal is copying a museum piece. Sacrifice victim for practice is a Traditions .50 Kentucky pistol kit.

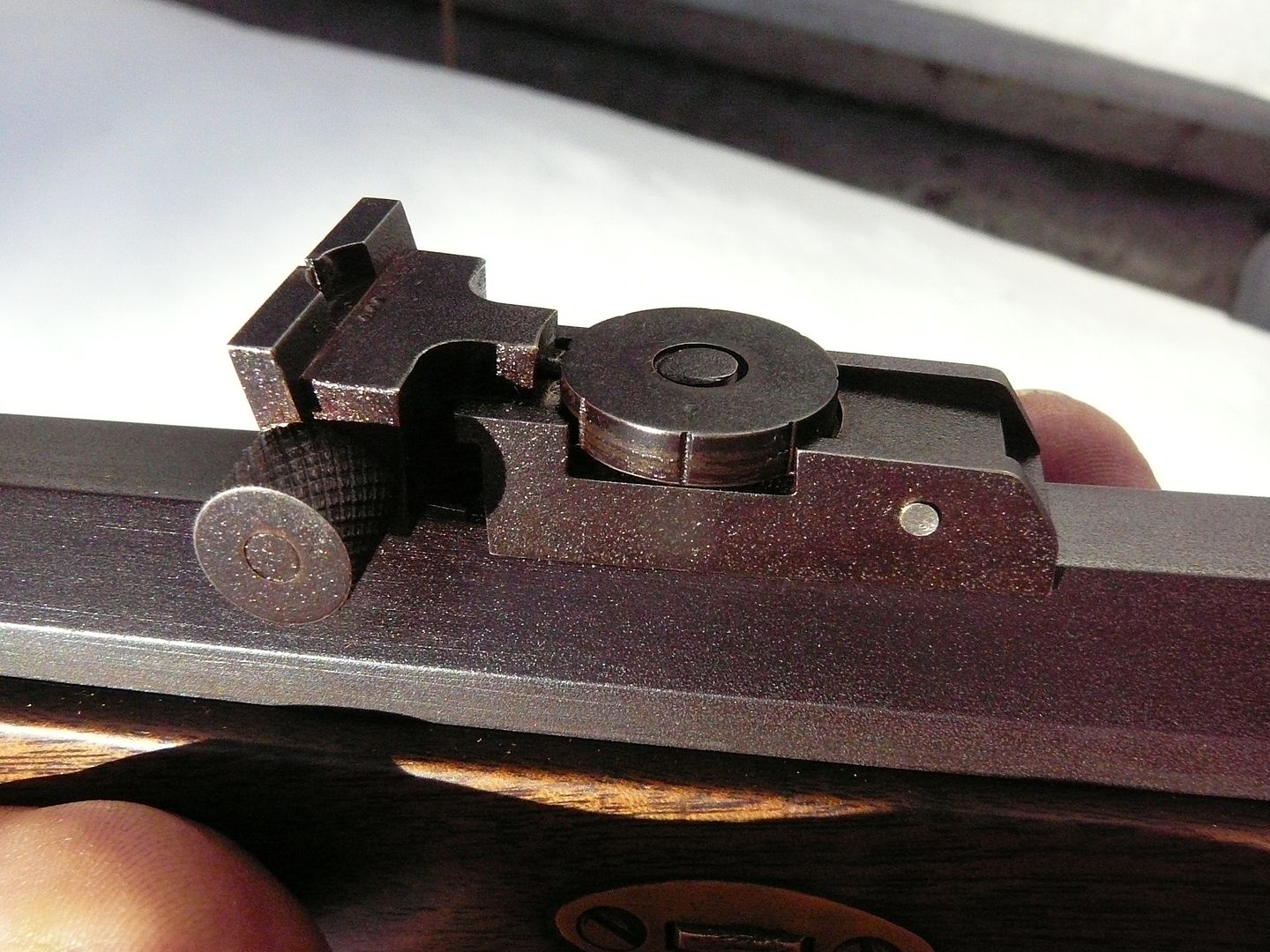

Here's the finish I'm going for: http://s288.photobucket.com/user/mahkagari/media/Rear_sight_zps8wnie9mt.jpg.html

Plan:

1) Remove any remaining wax with cloth and laquer thinner

2) Plug barrel with 1/2" wooden dowel

3) Apply LMF in single, even coat with a cloth without rubbing

4) Sweat box:

I'm in CO with pretty low humidity. After surfing around for ideas, I have 2" piece of ABS with a cap. I'm going to drill holes to thread baling wire to hang the barrel. That will stand in a mason jar of hot water. I have a home dry sauna (big cedar box big enough for one person to sit in with ceramic panel heaters) that goes up to 140F and can be run for 2 hours at a time. I'll stand the ABS-Mason jar contraption in that for 2 hours with the heaters on and let it sit for another hour or so as the sauna cools.

5) After first sweat, apply second coat sparingly, only enough to dampen barrel

6) Scale with denim and hot water

7) Repeat LMF application, sweat, and scale 4-5 times until desired color

8) Wash with hot water and baking soda solution, use a toothbrush for crevices

9) Rinse with hot water

10) Heat barrel to 120-130F

11) Apply motor oil and cure for 24 hours

12) Polish with soft cloth

13) Finish with gun oil

Miss anything? For heating the barrel, I can use the oven for a pistol, but I'll need to trust myself enough that I can heat it evenly with the torch to do a 36" barrel.

My ultimate goal is copying a museum piece. Sacrifice victim for practice is a Traditions .50 Kentucky pistol kit.

Here's the finish I'm going for: http://s288.photobucket.com/user/mahkagari/media/Rear_sight_zps8wnie9mt.jpg.html

Plan:

1) Remove any remaining wax with cloth and laquer thinner

2) Plug barrel with 1/2" wooden dowel

3) Apply LMF in single, even coat with a cloth without rubbing

4) Sweat box:

I'm in CO with pretty low humidity. After surfing around for ideas, I have 2" piece of ABS with a cap. I'm going to drill holes to thread baling wire to hang the barrel. That will stand in a mason jar of hot water. I have a home dry sauna (big cedar box big enough for one person to sit in with ceramic panel heaters) that goes up to 140F and can be run for 2 hours at a time. I'll stand the ABS-Mason jar contraption in that for 2 hours with the heaters on and let it sit for another hour or so as the sauna cools.

5) After first sweat, apply second coat sparingly, only enough to dampen barrel

6) Scale with denim and hot water

7) Repeat LMF application, sweat, and scale 4-5 times until desired color

8) Wash with hot water and baking soda solution, use a toothbrush for crevices

9) Rinse with hot water

10) Heat barrel to 120-130F

11) Apply motor oil and cure for 24 hours

12) Polish with soft cloth

13) Finish with gun oil

Miss anything? For heating the barrel, I can use the oven for a pistol, but I'll need to trust myself enough that I can heat it evenly with the torch to do a 36" barrel.

Last edited by a moderator: