Joe Sullivan

40 Cal.

- Joined

- Jul 27, 2011

- Messages

- 189

- Reaction score

- 0

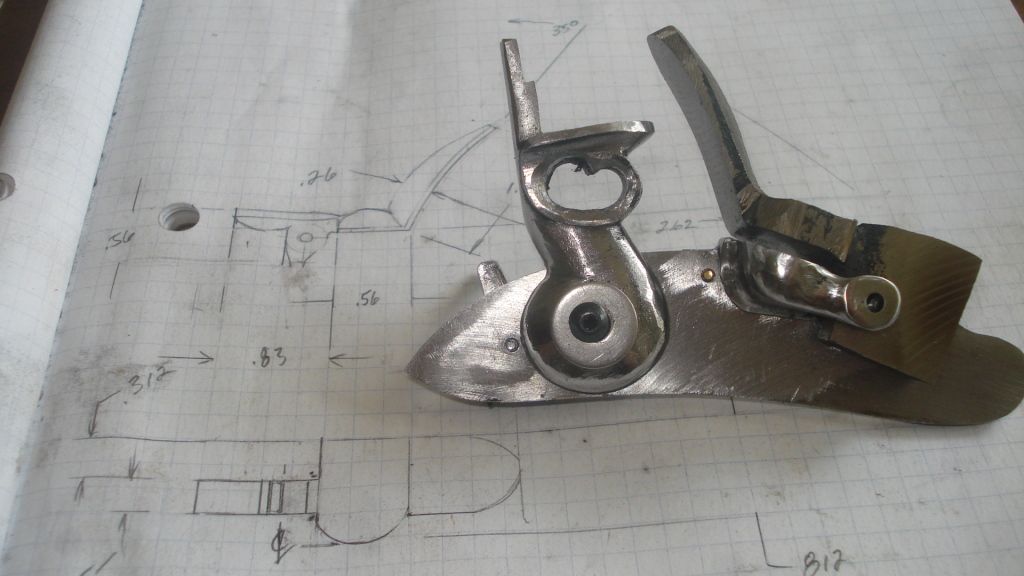

I'm ready to start my project. I have my pictures of the pistol printed to scale off of and a good set of dividers. I'm coming into my off season fishing. Plenty of time to do this.

I don't have much experience building so I would appreciate any input you might have. The double I made was my first build ever and it was my kickoff so to speak. I would like to post pics here, if you don't mind cause I like pics and I think most people do too.

The mooring chain my friend gave me is good quality steel. It hardened up great by super quench and I'm going to use it again.

Forged the corner, ground square, hacked off and drilled thru for #6 then drilled and press .145 dia rod. I'll tap 1/2" deep. A lot of meats coming off but its better to have than have not.

Hacksaw and file next.

I don't have much experience building so I would appreciate any input you might have. The double I made was my first build ever and it was my kickoff so to speak. I would like to post pics here, if you don't mind cause I like pics and I think most people do too.

The mooring chain my friend gave me is good quality steel. It hardened up great by super quench and I'm going to use it again.

Forged the corner, ground square, hacked off and drilled thru for #6 then drilled and press .145 dia rod. I'll tap 1/2" deep. A lot of meats coming off but its better to have than have not.

Hacksaw and file next.