Today I installed the barrel pins on my Tennessee Pre-Carve and things went much better than I first imagined it would.

As those of you who have bought a pre carve know, there aren't very many surfaces which are straight or square. In fact, most of them are curved. This can make drilling the barrel pin holes, should I say, interesting.

Although I have drilled many holes using just a electric hand drill it has always been one of those times when the old stomach was in a dam tight knot.

Getting the hole square with the stock was done by sitting a couple of combination squares next to the stock and eyeballing the angle of the drill relative to these references. More than once this caused the pin to break out the far side of the stock in less than ideal places.

This difficulty was one of the key drivers which caused me to buy a cheap 8 inch Chinese Drill Press. So far it has been a good tool to own.

Having the drill press still doesn't get the stock square with the drill but my method that follows does seem to square up the stock very well.

Backing up a couple of notches, the first thing that has to be done (after cutting the notches for the barrel underlugs in the stock) is to determine where to put the pins.

The fore/aft location may be eyeballed based on the underlugs location. Obviously you want it near the middle of the lug but the location does not have to be exact.

For the vertical location, you really should have a Dial (or electric) Caliper. These can be found for $20 and when you consider how many things you can do with them they are IMO well worth the money. (They measure outside, inside and depths to an accuracy of one thousanth of an inch).

If you have been good, and not started sanding the stock yet, you will have the two fairly straight surfaces on either side of the barrel channel.

These will serve to determine the location of the pin holes and to square up the stock for drilling.

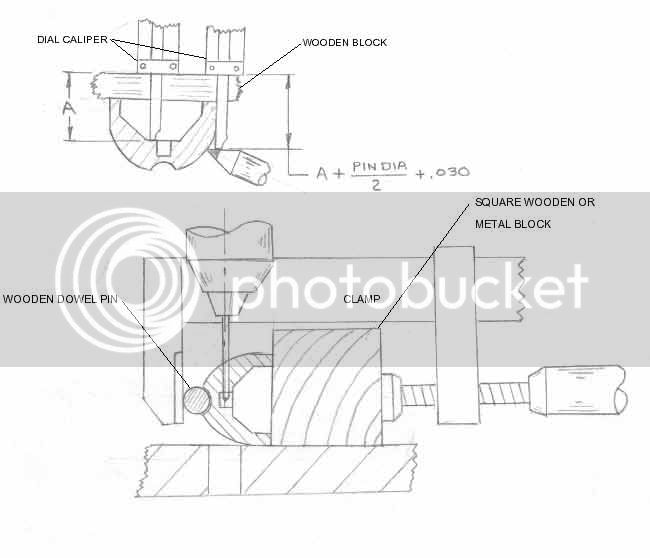

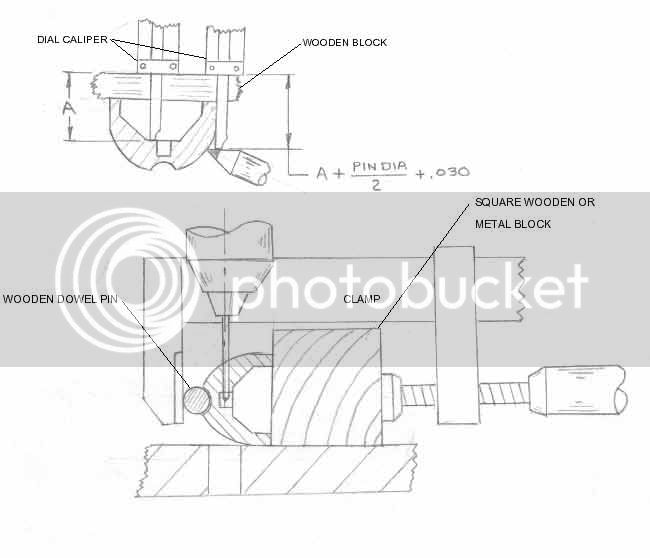

Note, the height of these surfaces to the bottom of the barrel channel may not be uniform so you have to measure the depth at each of the future pin holes. Take a look at the top drawing in the picture:

By using a small scrap of wood or metal with two parallel sides, you can bridge the barrel channel and measure down from the top of the bridge to the bottom flat in the barrel channel. This is dimension A. Don't worry about the number except you will have to add in the following location factor.

Adding 1/2 of the pin diameter and about .030 to the A dimension will give a good location for the barrel pin so calculate it and adjust the caliper to this number.

By moving the caliper to the outside of the stock (still resting on the bridge block), you can transfer this new location to the stock with a pencil.

Remember to do this at each pin location because the height of the channel walls to the bottom flat is usually different at different locations.

Referring to the lower picture, you can see that by using these straight surfaces adjacent to the barrel channel you can clamp a small block to the stock.

Use a wooden or metal dowel pin in the ramrod groove and use only enough pressure on the clamp to firmly hold it.

DO NOT clamp on the wood on either side of the ramrod groove. Clamp on the dowel as shown.

Also remember: Too much clamping pressure will split the stock right down the ramrod groove!

Resting the side of the stock and the bottom of the block on the drill press table to hold things straight and square while you drill.

Relocate the block and clamp for each pin hole and drill the remaining holes.

Notice that the barrel is not in the stock at this time.

Drill only one half way thru the wood to intersect the mortice for the underlug. Do not drill further yet.

Once all of the pin holes have been drilled half way thru the stock you can reinstall the barrel.

Make sure the breech of the barrel is seated against the end of the barrel channel.

Using the round dowel pin in the ramrod groove, clamp the barrel at the pin hole nearest to the breech.

Finishing the pin drilling can be done either on the drill press or by using a electric hand drill.

You might notice that with the barrel in place, the block which squared up the stock before cannot be used so I prefer the hand drill. The hand drill gives you a better "feeling" as the drill bit follows the existing pin hole and won't try to over-ride the angle of the pre existing hole like a drill press can. Try very hard not to let the drill "wallow" in the hole. You do not want to enlarge it.

Using the existing pin hole as a drill bushing guide for the drill will automatically put the hole in the underlug in just the right location. Finish drilling thru the barrel underlug and the far side of the stock.

Before you remove the clamp, install a barrel pin in the finished hole, then remove the clamp.

Repeat this at the middle pin hole and again at the muzzle pin hole.

You must drill these holes in this order to prevent binding which can occure if you drill the middle or breech hole last.

Have fun!

As those of you who have bought a pre carve know, there aren't very many surfaces which are straight or square. In fact, most of them are curved. This can make drilling the barrel pin holes, should I say, interesting.

Although I have drilled many holes using just a electric hand drill it has always been one of those times when the old stomach was in a dam tight knot.

Getting the hole square with the stock was done by sitting a couple of combination squares next to the stock and eyeballing the angle of the drill relative to these references. More than once this caused the pin to break out the far side of the stock in less than ideal places.

This difficulty was one of the key drivers which caused me to buy a cheap 8 inch Chinese Drill Press. So far it has been a good tool to own.

Having the drill press still doesn't get the stock square with the drill but my method that follows does seem to square up the stock very well.

Backing up a couple of notches, the first thing that has to be done (after cutting the notches for the barrel underlugs in the stock) is to determine where to put the pins.

The fore/aft location may be eyeballed based on the underlugs location. Obviously you want it near the middle of the lug but the location does not have to be exact.

For the vertical location, you really should have a Dial (or electric) Caliper. These can be found for $20 and when you consider how many things you can do with them they are IMO well worth the money. (They measure outside, inside and depths to an accuracy of one thousanth of an inch).

If you have been good, and not started sanding the stock yet, you will have the two fairly straight surfaces on either side of the barrel channel.

These will serve to determine the location of the pin holes and to square up the stock for drilling.

Note, the height of these surfaces to the bottom of the barrel channel may not be uniform so you have to measure the depth at each of the future pin holes. Take a look at the top drawing in the picture:

By using a small scrap of wood or metal with two parallel sides, you can bridge the barrel channel and measure down from the top of the bridge to the bottom flat in the barrel channel. This is dimension A. Don't worry about the number except you will have to add in the following location factor.

Adding 1/2 of the pin diameter and about .030 to the A dimension will give a good location for the barrel pin so calculate it and adjust the caliper to this number.

By moving the caliper to the outside of the stock (still resting on the bridge block), you can transfer this new location to the stock with a pencil.

Remember to do this at each pin location because the height of the channel walls to the bottom flat is usually different at different locations.

Referring to the lower picture, you can see that by using these straight surfaces adjacent to the barrel channel you can clamp a small block to the stock.

Use a wooden or metal dowel pin in the ramrod groove and use only enough pressure on the clamp to firmly hold it.

DO NOT clamp on the wood on either side of the ramrod groove. Clamp on the dowel as shown.

Also remember: Too much clamping pressure will split the stock right down the ramrod groove!

Resting the side of the stock and the bottom of the block on the drill press table to hold things straight and square while you drill.

Relocate the block and clamp for each pin hole and drill the remaining holes.

Notice that the barrel is not in the stock at this time.

Drill only one half way thru the wood to intersect the mortice for the underlug. Do not drill further yet.

Once all of the pin holes have been drilled half way thru the stock you can reinstall the barrel.

Make sure the breech of the barrel is seated against the end of the barrel channel.

Using the round dowel pin in the ramrod groove, clamp the barrel at the pin hole nearest to the breech.

Finishing the pin drilling can be done either on the drill press or by using a electric hand drill.

You might notice that with the barrel in place, the block which squared up the stock before cannot be used so I prefer the hand drill. The hand drill gives you a better "feeling" as the drill bit follows the existing pin hole and won't try to over-ride the angle of the pre existing hole like a drill press can. Try very hard not to let the drill "wallow" in the hole. You do not want to enlarge it.

Using the existing pin hole as a drill bushing guide for the drill will automatically put the hole in the underlug in just the right location. Finish drilling thru the barrel underlug and the far side of the stock.

Before you remove the clamp, install a barrel pin in the finished hole, then remove the clamp.

Repeat this at the middle pin hole and again at the muzzle pin hole.

You must drill these holes in this order to prevent binding which can occure if you drill the middle or breech hole last.

Have fun!