-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel stamp

- Thread starter juancho

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

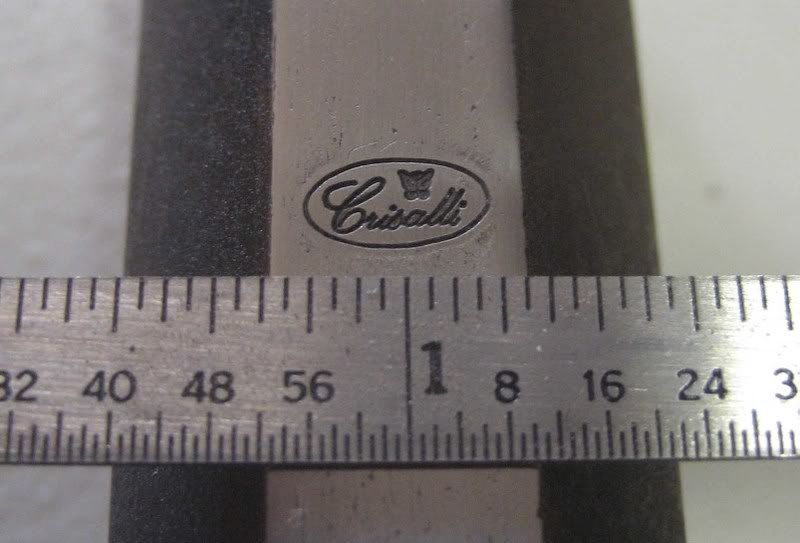

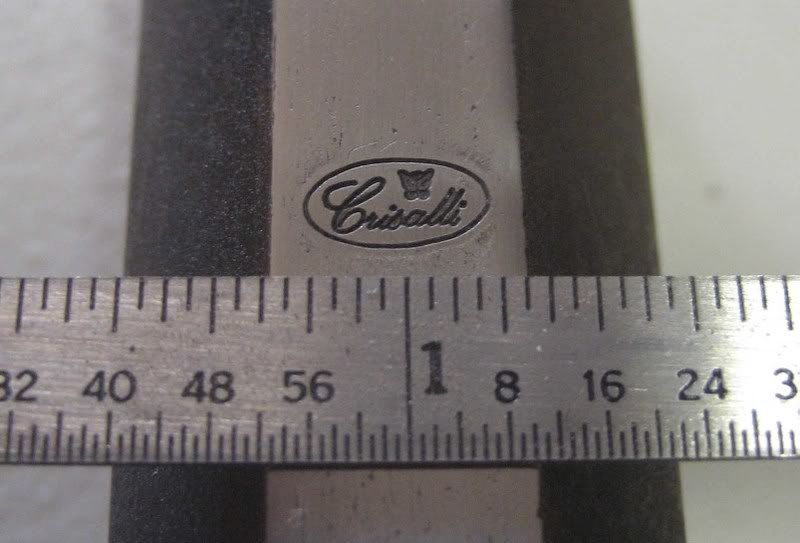

Looks to me like the stamp is 1/2" wide X 3/4" tall.

A octagon barrel would have to measure over 1.21" across the flats in order to have a barrel flat large enough to use that stamp.

The width of the barrel flat on a 7/8" octagon barrel is only .362 wide.

A octagon barrel would have to measure over 1.21" across the flats in order to have a barrel flat large enough to use that stamp.

The width of the barrel flat on a 7/8" octagon barrel is only .362 wide.

BE Wild Willy

40 Cal.

- Joined

- Jun 18, 2010

- Messages

- 276

- Reaction score

- 1

Looks like to me that he's using 32nd scale, and is 1/2" high x ?? wide. The mark looks nifty, what is it?

By scaling the screen, the actual stamp looks to be 3/8" high x 1/4" wide. That's a pretty fancy J, but I'm thinking the amount of force it would take to stamp the barrel would leave a pretty big bulge on the inside.

Paul

At first sight, I thought that was the stamp. Now I'm wondering if that is the actual impression from a capacitive discharge machine. Either way, it's pretty big for a barrel flat.

Paul

At first sight, I thought that was the stamp. Now I'm wondering if that is the actual impression from a capacitive discharge machine. Either way, it's pretty big for a barrel flat.

Yup. I screwed up on the size. :redface:

The stamp might look neat on a barrel flat but if that is tried, whoever does it needs to remember to get everything lined up. Then ONE strong blow from the hammer must be used and hope for the best.

The impact of the hammer will cause the punch to move and if it is struck after moving a double image will be made. At least that's what happened to me when ever I tried things like this.

Maybe the experts will chime in and help us both learn how the professional guys do it?

The stamp might look neat on a barrel flat but if that is tried, whoever does it needs to remember to get everything lined up. Then ONE strong blow from the hammer must be used and hope for the best.

The impact of the hammer will cause the punch to move and if it is struck after moving a double image will be made. At least that's what happened to me when ever I tried things like this.

Maybe the experts will chime in and help us both learn how the professional guys do it?

I'm no expert on those stamps, I use the single letters, but it does look like it would take a huge amount of force to make a clear impression in the metal. I too, wonder if it would affect the bore dimensions, though I'm pretty certain it would bulge out the outside of the flat surrounding the stamp. That metal has got to go somewhere. I'd sure try it on a cut off piece of barrel before using it on the real thing.

On a brighter note, it would make a great leather stamp :rotf: . Bill

On a brighter note, it would make a great leather stamp :rotf: . Bill

Most stamps were put on the angled flat on the sideplate side near the breech. Do not stamp over the breechplug as it may lock it in. Stamp over the powder chamber. Don't try to stamp 4140 barrel steel!

- Joined

- Mar 7, 2007

- Messages

- 702

- Reaction score

- 2,185

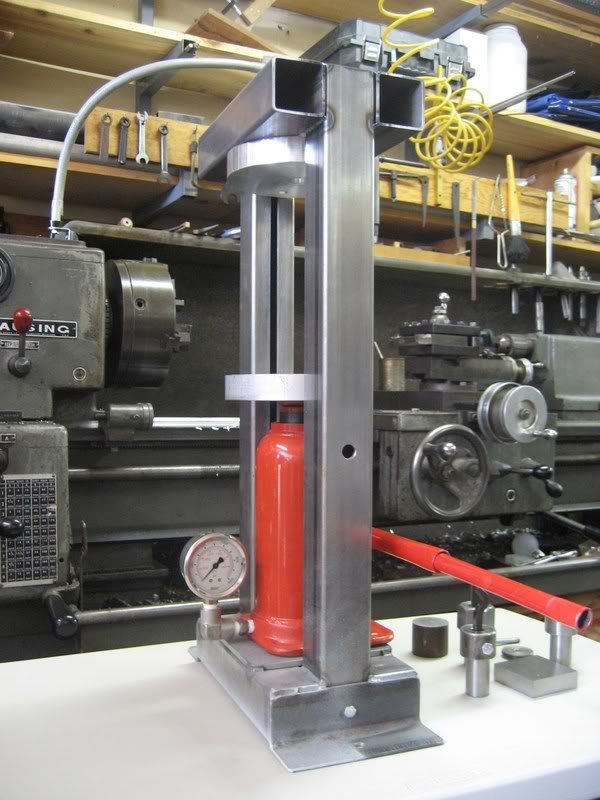

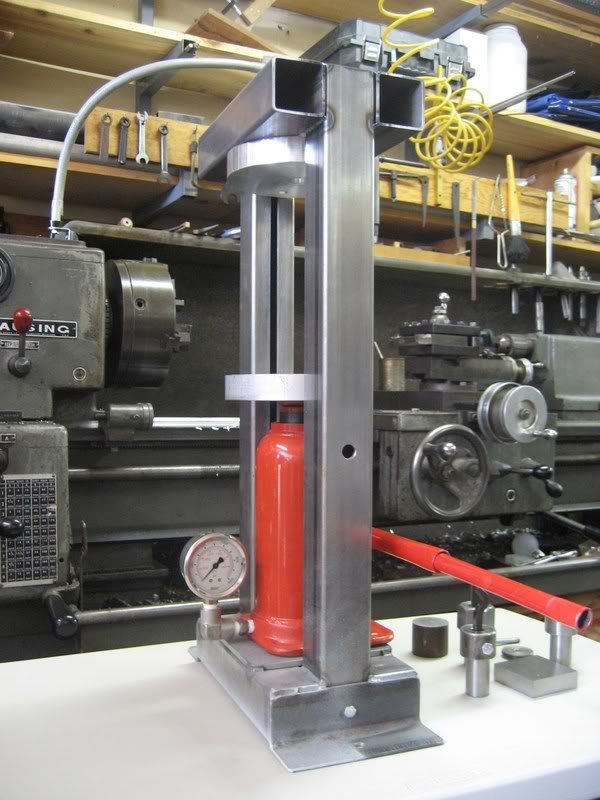

Zonie's mark looks like it was made by EDM (Electro Discharge Machining). If it was there are no tool forces involved and dimpling the inside of the barrel would not be an issue. I have seen such marks on the top flat or the next flat over away from the lock on several English originals. I never had much luck with the one giant hammer blow routine so I made this press.

This first picture is of the entire press. Â It is a simple welded assembly of 2 inch square tubing. Â A hydraulic jack, with a pressure gage that reads cylinder pressure, just sits on the bottom plate and pushed against the bottom of the lower, movable platten. Â The lower platten has two shoulder bolts 180 degrees apart that ride in slots milled in the vertical members. Â Inside the verticals, tension springs are attached to the shoulder bolts and to bolts running through the lower end of the vertical pillars. Â These springs will lower the platten when the bypass valve on the jack is opened. Â The upper platten is fixed to the upper horizontal frame members and has a 3/4 inch hole in the center. Â The center hole will accomodate different tool holders and / or anvils. Â I use the press to stamp, coin, bend tangs, bend barrels, punch out sheet, press powder, etc. Â Very handy tool.

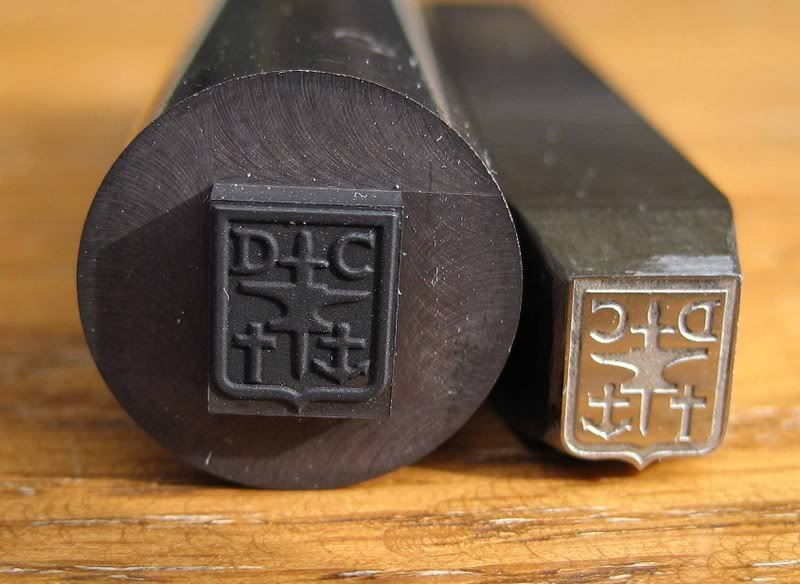

Stamps, tool holders, anvils, etc.

Close up of stamp in holder.

Stamp being used to mark a scrap piece of barrel.

In this particular case, 2000 psi is being applied to the press (this is the cylinder pressure but the cylinder has a cross sectional area of about 1.75 square inches which means that the applied force is about 3500 pounds.)

This is the resulting stamp impression. Â Very even and very repeatable with the pressure gage.

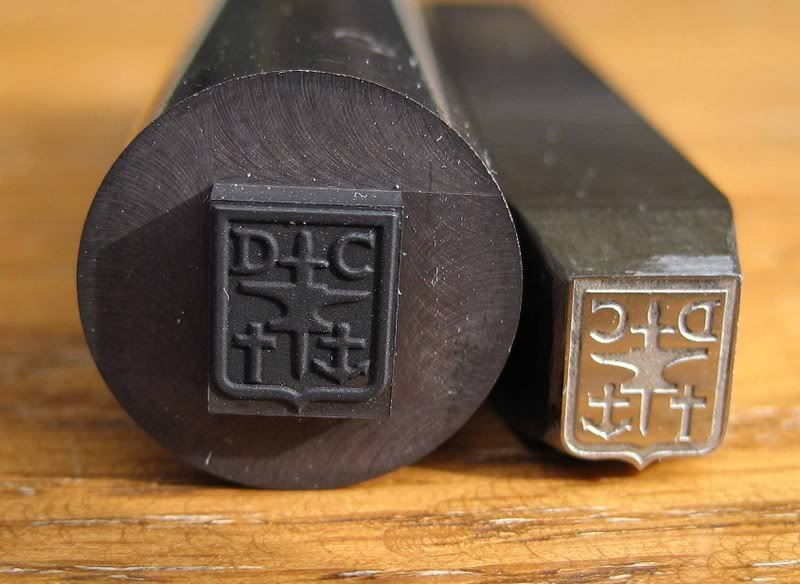

Graphite EDM tool to make coining (makers mark) stamps.

Some of my makers mark stamps.

Result of quick and dirty test pressing (really coining) of 24K gold, 0.025 inch thick in a recess quickly cut by hand graver in barrel steel. Â Pressed at 3200 psi hydraulic pressure - no distortion of the interior of the barrel (.45 cal, 13/ 16 across flats, no interior support)

This first picture is of the entire press. Â It is a simple welded assembly of 2 inch square tubing. Â A hydraulic jack, with a pressure gage that reads cylinder pressure, just sits on the bottom plate and pushed against the bottom of the lower, movable platten. Â The lower platten has two shoulder bolts 180 degrees apart that ride in slots milled in the vertical members. Â Inside the verticals, tension springs are attached to the shoulder bolts and to bolts running through the lower end of the vertical pillars. Â These springs will lower the platten when the bypass valve on the jack is opened. Â The upper platten is fixed to the upper horizontal frame members and has a 3/4 inch hole in the center. Â The center hole will accomodate different tool holders and / or anvils. Â I use the press to stamp, coin, bend tangs, bend barrels, punch out sheet, press powder, etc. Â Very handy tool.

Stamps, tool holders, anvils, etc.

Close up of stamp in holder.

Stamp being used to mark a scrap piece of barrel.

In this particular case, 2000 psi is being applied to the press (this is the cylinder pressure but the cylinder has a cross sectional area of about 1.75 square inches which means that the applied force is about 3500 pounds.)

This is the resulting stamp impression. Â Very even and very repeatable with the pressure gage.

Graphite EDM tool to make coining (makers mark) stamps.

Some of my makers mark stamps.

Result of quick and dirty test pressing (really coining) of 24K gold, 0.025 inch thick in a recess quickly cut by hand graver in barrel steel. Â Pressed at 3200 psi hydraulic pressure - no distortion of the interior of the barrel (.45 cal, 13/ 16 across flats, no interior support)

Neat.

You are correct, it is EDM.Only .015" deep and the stamp is .3x.5 inches.Cut the electrode on the CNC and burned it on the small EDM.

This is the electrode.

I'm going to make another one with the year in roman numerals MMXII to date the gun.

This is the electrode.

I'm going to make another one with the year in roman numerals MMXII to date the gun.

DOUBLEDEUCE 1

69 Cal.

- Joined

- Jan 25, 2008

- Messages

- 4,165

- Reaction score

- 877

Very interesting tool. :thumbsup:

- Joined

- Mar 7, 2007

- Messages

- 702

- Reaction score

- 2,185

Sorry, I meant Juancho's mark in my first sentence. Excellent EDM tool. Looks great. With EDM you don't care if the work piece is hardened or soft and, with no force being applied to the work piece, there are no distortions at all in any direction. Beautiful work, Juancho !

Ok , I decided to do it ,but I put the stamp in an odd place, kind of it atracts more attention that way.

This is the set up

and this is the result

I like it, but now I don't know what to do.Leave it polished or brown it.I will leave it white for a wile until I test fire it and set the sigths.

This is the set up

and this is the result

I like it, but now I don't know what to do.Leave it polished or brown it.I will leave it white for a wile until I test fire it and set the sigths.

Rich Pierce said:Most stamps were put on the angled flat on the sideplate side near the breech. Do not stamp over the breechplug as it may lock it in.

I stamp all of mine right over the breechplug threads with the breechplug in when I stamp it. Have not had any issues removing the plugs after the stamping. I have probably done 50 barrels like this. This insures I have not made an indentation in the bore. I did stamp a scrap piece of B-50 swamped Colerain barrel, about 1" from the breech, it indented the bore & I could see it with a light in the bore from breech end.

Keith Lisle

Similar threads

- Replies

- 25

- Views

- 598

- Replies

- 15

- Views

- 640