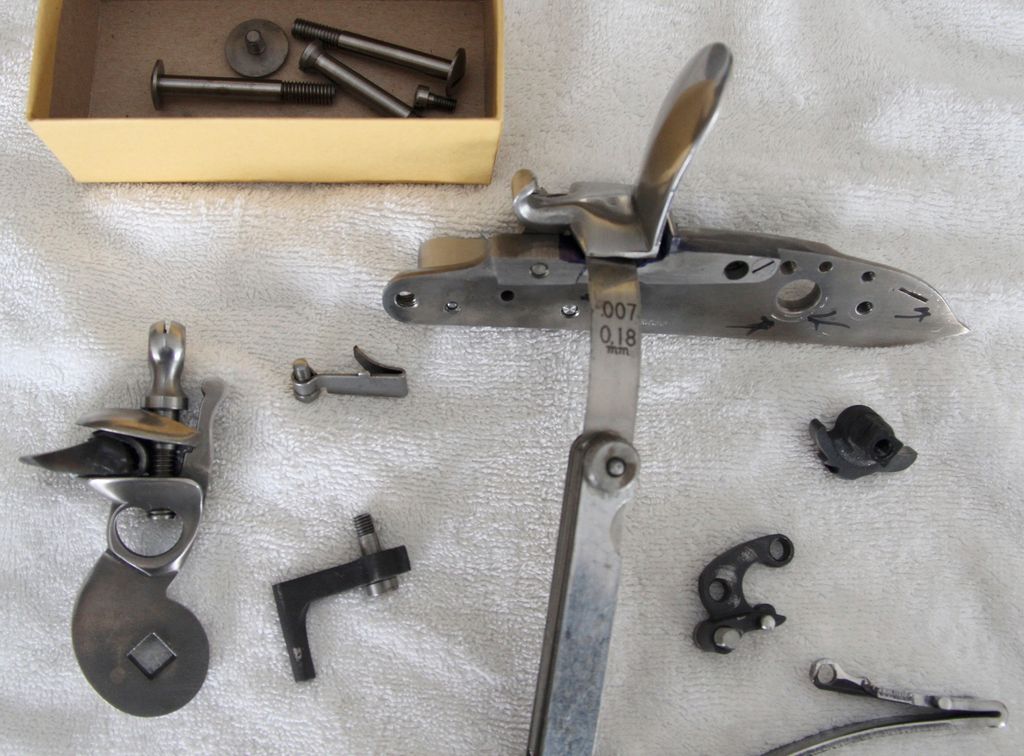

OK, some pictures of the 1766 David Pedersoli Charleville lock disassembled for inspection, de-burring, and polishing. I will post some more pictures of the pan, frizzen fit and progress later.

As I mentioned in another post, I checked on parts availability, price before I disassembled the lock. They are available, and they are not too expensive for my budget if I screwed a part up.

I took pictures before disassembly, during disassembly, after disassembly!

Arrows note scratches from rough cast parts rubbing lock plate. Rough boss on Tumbler

cutting grooves in lock plate, Burr on main spring gouging lock plate, unpolished internal parts, sear, bridle showing metal to metal wear, sear spring has sharp edge from being stamped out, it was scratching lock plate. Lock plate hole for tumbler shaft had sharp edge from drilling. I chamfered that with emery paper. Frizzen to pan gap is .007" at front of pan. Only place frizzen is seated on the pan is two rear corners at far edge of 95 degree bend from horizontal to vertical. I'm glad the cock screw was loose, or damage to lock plate would have been worse. Lock had only been test fired at factory one time, and I spark tested it myself (excellent results btw!), cocked several times to measure spring tension, trigger pull.

Dykem was used on the pan to determine where frizzen (hammer) was making contact. Pan had a sharp edge at radius where it contacts the barrel. I have polished that out of it, and am in the process of finishing the polishing of the pan channel, using progressively finer wet/dry emery paper with a drop of oil. Sear, tumbler, and bridle all as cast, minimal polishing if any. Main spring was highly polished, but had burrs/high spots that were not removed.

Gap at front of pan/frizzen is .007" on the inside edge tapering to .006" at outside edge. .007" feeler gauge will not push through without lifting pan a tick, .006" will slip though to external side of lock.

Sear spring has sharp edge where is contacts the lock plate, small burrs.

Tumbler was removed by taping brass punch, just the right size to fit in square hole of cock, with a small plastic hammer. (per Comfortably_Numb's input), my old, used, and out of print copy of Black Powder Hobby Gunsmithing by Sam Fadala and Dale Storey, showed using a smaller punch in the threaded cock screw hole. CN said he punched through a tumbler doing it that way. My tumbler came off with the slightest tap, leaving no transfer of brass from the punch on the rough steel end of tumbler shaft. It was a interference fit into cock square hole, but not really a tight, pressed into, interference fit. In other words, it's made to be disassembled/reassembled. I believe it is best practice to use the larger punch on the end of tumbler shaft, better safe than sorry.

What I have learned.

Pedersoli makes a great mass production piece. Better than most of the competition in my experience! They are pricey, but you get what you pay for. Lock is sound, geometry is very good, but not ideal. Parts fit as they should, (with the exception of pan to frizzen fit), hand polishing is minimal, if at all, on metal to metal contact parts, Sear was unpolished. De-burring is hit or miss, both main spring and sear spring had sharp edges or burrs or both. Lubrication is minimal, or in the case of pan/barrel/vent area, in a location it should not be! YMMV. Main spring is heavy IMHO, mine was 12 lbs. 8-10 is better, but I was expecting it to be much higher. Geometry of springs is very good to excellent. Frizzen spring is heavy at 4 lbs. 12 oz., but it breaks easy due to good geometry on radius, and fair polishing of top of spring.

My take away.

Based on what I found, AND, input/expertise of other members, especially: Dave_Person, FlinterNick, Gus and others? I am pleased with the quality of the Pedersoli Charleville rifle. The lock is very nice, external finish is excellent! Lock geometry is excellent, four out of five stars, but not perfect. Pan was set low, boss drilled off a tad, and could have been honed a bit to improve, adjust for it. Frizzen is hard, excellent spark test! Lock will be much smoother after tuning, damage from metal to metal wear will be greatly reduced!

What I would do different.

1st thing, I would check all external screws to see they are at least snug, Cock screw was not even snug! Bridle screw was not even hand tight! I would take the lock down sooner rather than later. I wouldn't even spark test till I looked at lock internals. There is no damage to lock plate or parts that can't be addressed, fixed, polished/honed to improve. However, I could have saved myself some work, by not playing with the lock until after I inspected and tuned it.

Summary: Out of the box the Pedersoli 1766 is an excellent example of a mass produced production piece. It is not an exact HC reproduction of the 1766 Charleville musket. Stock is thick at wrist, piece is heavy as the 1763 Leger was (10.5 pounds) a true 1766 was 1.5 pounds lighter. The true 1766 had a button ramrod IIRC. It has a heavy barrel as did the 1763 as well. I like that! The barrel is polished inside and out. Very slick bore with a tight jab and patch. Stock comb is too high for some people. It fits me fine with the drop in the butt stock. American Walnut stock is nicely figured, dense, and beautiful, wood to metal fit is excellen! Dave_Person excellent? Probably not, but that is comparing apples to oranges. Dave makes custom, hand fit, HC if desired, master pieces he puts his talent and heart and sole into! And, he can defarb and make a production gun into a custom, HC masterpiece if you desire. Yeah, I'm jealous, can you tell? Kudos to you Dave, your my hero, and mentor! Tough, I will never have your talent, especially with the wood work!

The lock is better than most competitors, much better than some! Even better, I am told by those in the know, than Pedersoli's Brown Bess. It is an expensive smooth bore military musket. Is it worth the cost? If you don't want to pay more for a custom gun from one of the forum members, or other masters in the trade. If you are content with it not being HC in the stock geometry and barrel, and weight, and don't mind doing some tuning to the lock, my answer is yes! Even if you want a HC 1766, with lock tuning, there are master gunsmiths that will do that for you, defarb, correct stock, tune the lock. It is a matter of choice and how much you are willing to spend, and or do yourself.

For my part, I like the stock, always have. Some think the so called Roman Nosed, Calf Leg, comb is ugly. To each his own. I went back and forth trying to decide if I wanted a Bess or a Charleville. I decided I wanted something a bit different. All the SAR members in my Chapter have Bessies! As always, I read and studied up on the pros and cons of both. I am pleased with my choice, I love the looks of it. My 1861 Springfield has many of th e same features, and there is no doubt the Americans copied from the French design. I was delighted to learn how easy it is to break down for a deep clean, much less trouble than a Bess. In fact some Brown Bess shooters, never tear them down for a deep clean, worried they will damage the stock, barrel pins, tenons with repeated disassembly. To each his own. I like the brass pan, muzzle, and wrist inlay of the Brown Bess. In the end I chose the Charleville, and I am pleasantly pleased I did! Do I believe the Brown Bess is an inferior musket? Absolutely not, I'd be delighted to own one, and many of our members have both! Bess & Charleville! I'd sure love to! YMMV.

OK muzzleloading forum mind trust, have at me! You may say my opinions and advice isn't worth my forum name sake! You you wouldn't be the first to tell me that!

Opinions, constructive criticisms, corrections, brain fart redactions, and most importantly, expert advice and tips/fixes are welcomed! Remember please, I am new at this hobby, and still have a LOT to learn.

Nickel