gunsports

32 Cal.

- Joined

- Aug 30, 2009

- Messages

- 35

- Reaction score

- 4

Just a bit of an update.

We’ve managed to reduce the time difference down to 1/25th of a second.

First, we established a bench mark using Wano FFg black powder for the main charge, and Swiss 4F as the prime. (Load was 80gn vol.) A consistent time of 4/25th of a second was recorded; using the test equipment we had available. The rifle used was an Isaac Haines inspired long rifle; .58 cal, Rice 44” swamped octagonal barrel, Chambers lock and a double set trigger.Vent was a White Lightning, with a 1/16th orifice.

We then used our locally available substitute powder (rifle grain); again 80gr (vol.) as the main charge and for the prime, used a 50/50 mixture of Swiss 4F and substitute powder; this time the pistol grain. Ignition time was consistent at 5/25th of a second.

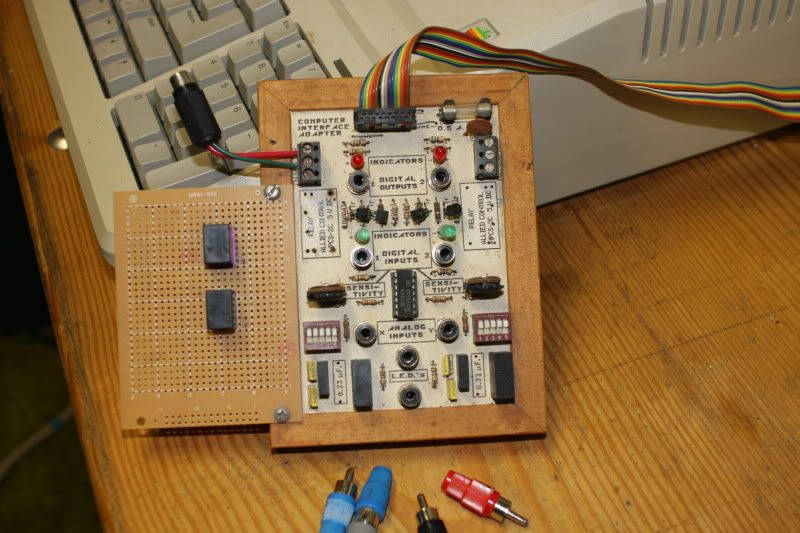

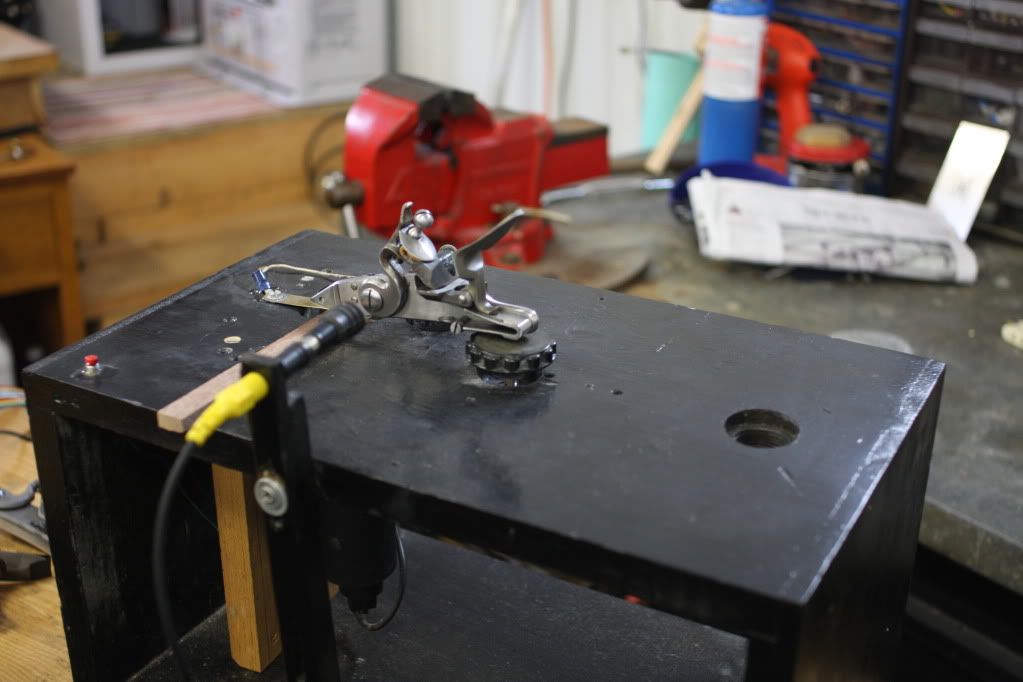

Our ”˜testing’ equipment consisted of a Panasonic video camera, recording at 25 frames per second. Film clips of the gun firing was recorded and them; individual frames were viewed on the computer using Nero 7 software. Frames were counted as follows: -

The frame where hammer movement was first observed; was counted as frame no. 2. Subsequent frames were then counted till there was a plume of smoke from the barrel, signalling that the bullet had exited. This was the last frame counted. Thus, we counted frame one: The sear tripping; frames 2 ”“ 3: Ignition and frame 4: The bullet having left the barrel. As the recording and playback speed of the film clip was 25 frames per second; a series of 4 consecutive frames would then count as 4/25th of a second, and so on.

Our measuring methods may be on the primitive side, but we obtained a fair indication of the ignition times of the two powder types used. In fact, with better testing equipment, faster times could be possible; as time intervals can be more accurately measured.

Now, 1/25th of a second may seem a long time but in reality, there was no observable difference in the actual firing of the rifle.

Some valuable observations were made and which may be of interest.

One: Black powder ignites best by radiant heat; hence the recommendation that the prime should be positioned below the vent. Substitute powder on the other hand, ignites best by direct flame, thus the vent should be covered to provide a continuous burn path.

Two: The ignition temperature of substitute powder is much higher than black powder; hence the mix of substitute powder and 4F priming powder; this to raise the ignition temperature. Tests using substitute powder with a prime of 4F only, or a prime of substitute powder only, showed significantly slower ignition times.

Three: Most quality built flint lock guns have the vent placed in line with the top of the pan. Now, to affect a continuous burn path between prime and the main charge, much more priming powder is needed to cover the vent. (There is no benefit in ”˜banking’ the powder against the vent; as movement of the rifle will displace the powder away from the vent, slowing ignition times.) Thus, if a flint lock rifle is being built for use with substitute powder only, consideration should be given to placing the vent lower. Our remedy here for existing guns is to line the vent with some sheet brass; soft soldered in; this to lift the floor of the pan and thus reducing the amount of priming powder needed.

Four: Substitute powders ignite best (and fastest) when the ignition flame is under pressure; like in a percussion cap. This is, to my view, one of the main reasons for the ignition delays when using substitute powders in a flint lock. There is no remedy.

These tests were repeated with two other flint lock guns. One was a commercially bought Euroarms ”˜Kentuckian’; the other a purpose built 12 bore smooth rifle using a Colerain Griffen 42” swamped smooth barrel and a Petersoli Grice (Brown Bess lock). Although different ignition times were recorded (The ”˜Bess lock is very slow), the time differences between black and substitute powder was the same: 1/25th of a second.Both were fitted with White Lightning vents, 1/16th orifices.

Duplex loads, like those recommended by certain manufacturers, were also tried. But, we found that the small charge of 5gr of 4F powder behind the substitute powder; in especially large calibre barrels, gave inconsistent ignition times. ”˜Booster’ charges in the region of 15 ”“ 25gr of black powder (NOT priming powder), proved far more reliable and consistent.

Tests were also conducted with combustible (cigarette paper) paper powder cartridges; where a duplex load; consisting of about 10gr of 2F black powder, behind a substitute powder was loaded. This proved most successful, with ignition times equal to that of using black powder only. But, the user had to pierce the cartridge through the vent to ensure 100% ignition. Priming was as for normal black powder loads.

In conclusion: We’ve basically reduced the firing delays when using substitute powders in flint guns to a level where it is not observable in normal use; provided some adjustment in priming methodology is observed.

I post this as; from the reading on this and other sites, you have areas in the ”˜States where black powder is becoming difficult to source and, to save both time and expense, substitute powders may have to be considered. I have no experience with the powders available over there, but a substitute powder, close in characteristics to that available over here; may prove successful in your flint lock guns.

Glen McGill

Oudtshoorn

South Africa.

We’ve managed to reduce the time difference down to 1/25th of a second.

First, we established a bench mark using Wano FFg black powder for the main charge, and Swiss 4F as the prime. (Load was 80gn vol.) A consistent time of 4/25th of a second was recorded; using the test equipment we had available. The rifle used was an Isaac Haines inspired long rifle; .58 cal, Rice 44” swamped octagonal barrel, Chambers lock and a double set trigger.Vent was a White Lightning, with a 1/16th orifice.

We then used our locally available substitute powder (rifle grain); again 80gr (vol.) as the main charge and for the prime, used a 50/50 mixture of Swiss 4F and substitute powder; this time the pistol grain. Ignition time was consistent at 5/25th of a second.

Our ”˜testing’ equipment consisted of a Panasonic video camera, recording at 25 frames per second. Film clips of the gun firing was recorded and them; individual frames were viewed on the computer using Nero 7 software. Frames were counted as follows: -

The frame where hammer movement was first observed; was counted as frame no. 2. Subsequent frames were then counted till there was a plume of smoke from the barrel, signalling that the bullet had exited. This was the last frame counted. Thus, we counted frame one: The sear tripping; frames 2 ”“ 3: Ignition and frame 4: The bullet having left the barrel. As the recording and playback speed of the film clip was 25 frames per second; a series of 4 consecutive frames would then count as 4/25th of a second, and so on.

Our measuring methods may be on the primitive side, but we obtained a fair indication of the ignition times of the two powder types used. In fact, with better testing equipment, faster times could be possible; as time intervals can be more accurately measured.

Now, 1/25th of a second may seem a long time but in reality, there was no observable difference in the actual firing of the rifle.

Some valuable observations were made and which may be of interest.

One: Black powder ignites best by radiant heat; hence the recommendation that the prime should be positioned below the vent. Substitute powder on the other hand, ignites best by direct flame, thus the vent should be covered to provide a continuous burn path.

Two: The ignition temperature of substitute powder is much higher than black powder; hence the mix of substitute powder and 4F priming powder; this to raise the ignition temperature. Tests using substitute powder with a prime of 4F only, or a prime of substitute powder only, showed significantly slower ignition times.

Three: Most quality built flint lock guns have the vent placed in line with the top of the pan. Now, to affect a continuous burn path between prime and the main charge, much more priming powder is needed to cover the vent. (There is no benefit in ”˜banking’ the powder against the vent; as movement of the rifle will displace the powder away from the vent, slowing ignition times.) Thus, if a flint lock rifle is being built for use with substitute powder only, consideration should be given to placing the vent lower. Our remedy here for existing guns is to line the vent with some sheet brass; soft soldered in; this to lift the floor of the pan and thus reducing the amount of priming powder needed.

Four: Substitute powders ignite best (and fastest) when the ignition flame is under pressure; like in a percussion cap. This is, to my view, one of the main reasons for the ignition delays when using substitute powders in a flint lock. There is no remedy.

These tests were repeated with two other flint lock guns. One was a commercially bought Euroarms ”˜Kentuckian’; the other a purpose built 12 bore smooth rifle using a Colerain Griffen 42” swamped smooth barrel and a Petersoli Grice (Brown Bess lock). Although different ignition times were recorded (The ”˜Bess lock is very slow), the time differences between black and substitute powder was the same: 1/25th of a second.Both were fitted with White Lightning vents, 1/16th orifices.

Duplex loads, like those recommended by certain manufacturers, were also tried. But, we found that the small charge of 5gr of 4F powder behind the substitute powder; in especially large calibre barrels, gave inconsistent ignition times. ”˜Booster’ charges in the region of 15 ”“ 25gr of black powder (NOT priming powder), proved far more reliable and consistent.

Tests were also conducted with combustible (cigarette paper) paper powder cartridges; where a duplex load; consisting of about 10gr of 2F black powder, behind a substitute powder was loaded. This proved most successful, with ignition times equal to that of using black powder only. But, the user had to pierce the cartridge through the vent to ensure 100% ignition. Priming was as for normal black powder loads.

In conclusion: We’ve basically reduced the firing delays when using substitute powders in flint guns to a level where it is not observable in normal use; provided some adjustment in priming methodology is observed.

I post this as; from the reading on this and other sites, you have areas in the ”˜States where black powder is becoming difficult to source and, to save both time and expense, substitute powders may have to be considered. I have no experience with the powders available over there, but a substitute powder, close in characteristics to that available over here; may prove successful in your flint lock guns.

Glen McGill

Oudtshoorn

South Africa.