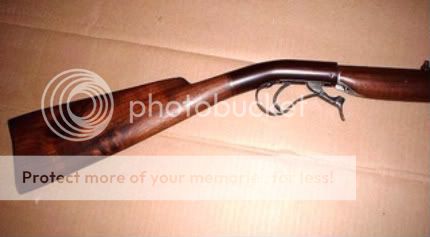

Just recently put together an underhammer I picked up from blue grouse. I had to shorten the breech plug for my GM barrel that I was using in order for it to fit properly with the under hammer action. I did this using a grinder being as carefull as possible to keep the face square.

My question is should I find someone with a lathe to properly square the face up or will I be ok with the eyeballing/grinder job I did?

Cheers

My question is should I find someone with a lathe to properly square the face up or will I be ok with the eyeballing/grinder job I did?

Cheers