- Joined

- Nov 26, 2005

- Messages

- 5,218

- Reaction score

- 10,867

Hi,

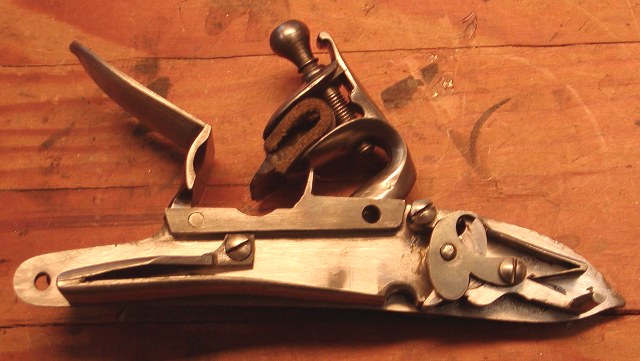

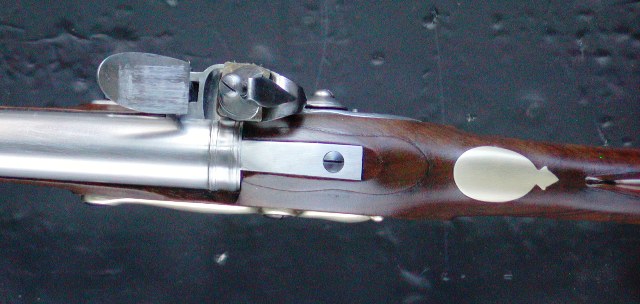

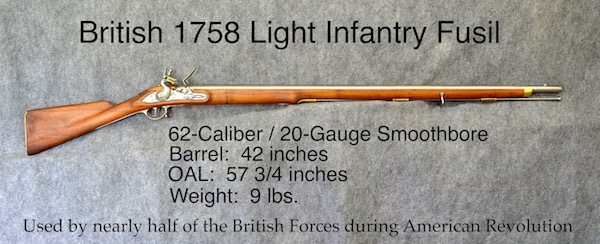

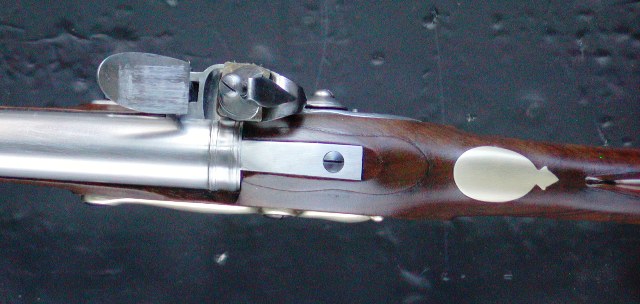

It is done. The final tung oil-varnish finish came out nicely. I finished the ramrod and filed and polished up the bayonet. The front sight/bayonet lug on the barrel is fitted to a shallow dovetail and then silver soldered in place. On originals it would be brazed but you won't be able to tell the difference. The vent hole was a problem because the pre-inlet stock did not allow me to move the barrel back very much or position the lock further forward. As such, the vent hole hit smack into the end of the breech plug. This is why locks should never be pre-inlet unless you have a Kibler kit. I solved the problem by installing a white lightning vent liner at a slight forward angle and drilling the vent hole larger. The hole is a little forward of center of the pan but that will not make any difference. Ignition will be fast and reliable. The bayonet is fitted to the barrel with no slop or wobble and the forward slot for the lug has a slight taper so the lug snugs in place. This is a bayonet and installation that could really be used and is not just for show.

The stock is American black walnut but finished to look more like English walnut. I used sandpaper to some extent but the finished surface was created mostly with files and scrapers. The finish is Sutherland-Welles polymerized tung oil for the first sealer coats and then S-W wiping varnish after. The wiping varnish is polymerized tung oil mixed with polyurethane varnish and is medium gloss.

This is likely the most slim and elegant of all the regular issue British military guns of the 18th century. However, the parts set has some errors and limitations. First, and foremost, the butt stock is too thin. They needed to leave more wood on the sides of the comb to give it a more bulbous shape more like the earlier pattern Besses. Instead, after removing all the router marks, what is left is too flat sided and is more like later Bess patterns. Of course, there was certainly variation in the stocks so mine may still be historically accurate but I wish TRS would let the maker make that decision.

The parts set has a typical Bess brass trigger plate supplied and pre-inlet. That is a huge mistake because these carbines did not have trigger plates, just a slot in the wood and the tang bolt was threaded into a rectangular iron nut inlet forward of the trigger. I fitted a wood patch into the inlet for the trigger plate and then made and inlet a steel nut.

The stock was routed and drilled for a metal ramrod. None of these carbines were issued with metal rods. All had 5/16" wooden ramrods. I had to widen the ramrod groove and drill out the hole to fit a proper wooden rod. That also meant drilling out all of the ramrod pipes.

. The parts set uses the trigger guard from the Lord Loudoun carbine. The rear extension of that guard flares a bit at its end. The pattern 1760 guard does not flare out and would be much easier to inlet. The machine inlet for the wide flare at the end means the edges of that inlet are so thin and fragile that they cannot possibly survive the building process. They simply crumble away particularly since the stock is American black walnut. I had to fit the rear extension deeper to solve that, which also meant filling the old hole and drilling a new one for the cross pin.

The parts set also has a cast nosecap, which is wrong. They all had sheet brass nose bands of which mine is open on the end like most of the originals.

The pattern 1756 carbine lock is superb. I am sure it will work all the time. The lock plate as purchased had "Farmer 1759" cast-in engraved on the tail. It is possible Farmer made locks used on the carbines but none of the surviving examples of which I am aware have that contractors name. So I filed it off and engraved "Vernon 1757", which is known on several surviving examples in North America.

The 0.65 caliber Rayl barrel is beautiful and very well balanced. I'll take it out for a test run later in March and then I'll offer it for sale first to the British Brigade. If not sold by summer, I'll have it at Dixon's for sale. For comparison, below are some photos of an India-made version currently sold by some vendors. I think mine is almost as good. By the way, mine weighs 7.5 lbs. and is 65 caliber.

dave

It is done. The final tung oil-varnish finish came out nicely. I finished the ramrod and filed and polished up the bayonet. The front sight/bayonet lug on the barrel is fitted to a shallow dovetail and then silver soldered in place. On originals it would be brazed but you won't be able to tell the difference. The vent hole was a problem because the pre-inlet stock did not allow me to move the barrel back very much or position the lock further forward. As such, the vent hole hit smack into the end of the breech plug. This is why locks should never be pre-inlet unless you have a Kibler kit. I solved the problem by installing a white lightning vent liner at a slight forward angle and drilling the vent hole larger. The hole is a little forward of center of the pan but that will not make any difference. Ignition will be fast and reliable. The bayonet is fitted to the barrel with no slop or wobble and the forward slot for the lug has a slight taper so the lug snugs in place. This is a bayonet and installation that could really be used and is not just for show.

The stock is American black walnut but finished to look more like English walnut. I used sandpaper to some extent but the finished surface was created mostly with files and scrapers. The finish is Sutherland-Welles polymerized tung oil for the first sealer coats and then S-W wiping varnish after. The wiping varnish is polymerized tung oil mixed with polyurethane varnish and is medium gloss.

This is likely the most slim and elegant of all the regular issue British military guns of the 18th century. However, the parts set has some errors and limitations. First, and foremost, the butt stock is too thin. They needed to leave more wood on the sides of the comb to give it a more bulbous shape more like the earlier pattern Besses. Instead, after removing all the router marks, what is left is too flat sided and is more like later Bess patterns. Of course, there was certainly variation in the stocks so mine may still be historically accurate but I wish TRS would let the maker make that decision.

The parts set has a typical Bess brass trigger plate supplied and pre-inlet. That is a huge mistake because these carbines did not have trigger plates, just a slot in the wood and the tang bolt was threaded into a rectangular iron nut inlet forward of the trigger. I fitted a wood patch into the inlet for the trigger plate and then made and inlet a steel nut.

The stock was routed and drilled for a metal ramrod. None of these carbines were issued with metal rods. All had 5/16" wooden ramrods. I had to widen the ramrod groove and drill out the hole to fit a proper wooden rod. That also meant drilling out all of the ramrod pipes.

. The parts set uses the trigger guard from the Lord Loudoun carbine. The rear extension of that guard flares a bit at its end. The pattern 1760 guard does not flare out and would be much easier to inlet. The machine inlet for the wide flare at the end means the edges of that inlet are so thin and fragile that they cannot possibly survive the building process. They simply crumble away particularly since the stock is American black walnut. I had to fit the rear extension deeper to solve that, which also meant filling the old hole and drilling a new one for the cross pin.

The parts set also has a cast nosecap, which is wrong. They all had sheet brass nose bands of which mine is open on the end like most of the originals.

The pattern 1756 carbine lock is superb. I am sure it will work all the time. The lock plate as purchased had "Farmer 1759" cast-in engraved on the tail. It is possible Farmer made locks used on the carbines but none of the surviving examples of which I am aware have that contractors name. So I filed it off and engraved "Vernon 1757", which is known on several surviving examples in North America.

The 0.65 caliber Rayl barrel is beautiful and very well balanced. I'll take it out for a test run later in March and then I'll offer it for sale first to the British Brigade. If not sold by summer, I'll have it at Dixon's for sale. For comparison, below are some photos of an India-made version currently sold by some vendors. I think mine is almost as good. By the way, mine weighs 7.5 lbs. and is 65 caliber.

dave

Last edited: