1861colt

40 Cal

- Joined

- Feb 19, 2019

- Messages

- 107

- Reaction score

- 74

WOW! Blow me over with a marshmallow gun (flintlock of course)! You just showed us your top shelf stuff. I hated using walnut stock filler because it takes the glow out of the depth of the grain. I used many layers of Birchwood Casey Tung Oil that took a while to fill the grain. However, your use of sandpaper dipped in the oil got the majority of the work done in two coats. It manages to take sawdust that is already stained and repurposing it as the filler and because of the oil as a lubricant on the sandpaper, the grains don't come off plugging up the pores where they can sit there and look ugly.On a higher-end civilian gun, I urge you to add another step, one that really makes a difference in the smoothness of the finish on walnut. After all the staining, apply the first coat of oil, oil-varnish, or varnish with 220 grit sandpaper. Dip the sandpaper in the finish and sand the wood until you create a slurry of finish and sawdust. Do the complete stock that way and let the slurry dry on the stock for a day or two. Then use 320 grit paper to sand off the dried slurry. It will have filled the grain leaving behind a nice glassy smooth surface. Sometimes I do this twice but usually only once. Then apply sparing coats of finish until you get the sheen you want. I usually tint the finish with alkanet root. The guns below were finished in that manner.dave

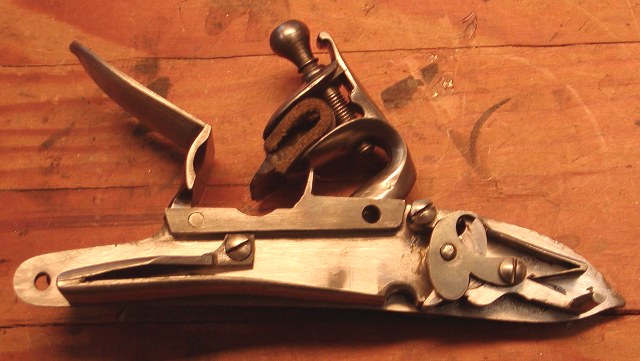

See some nice colors in your hardware. Would you reveal the secrets to getting the dark blue/purple/black (pictures can be hard to decipher) on the trigger guard and the breech/tang. And, while you are at it, what about the barrel plum brown color.