Herb said:A really great tutorial, Spikebuck. Got a question: are you saying that clamping the tang down for 24 hours will put a permanent bend in it to conform to the wood? I just spent about four hours bending and rebending my flint tang to match my hand-sawed stock.

Well, Herb...first I want to say how much I appreciate all the photos, measurements, etc you have been providing! I've never seen a "real" Hawken and your hands-on experience and willingness to share that has been a true blessing to me. So special thanks to you. :hatsoff:

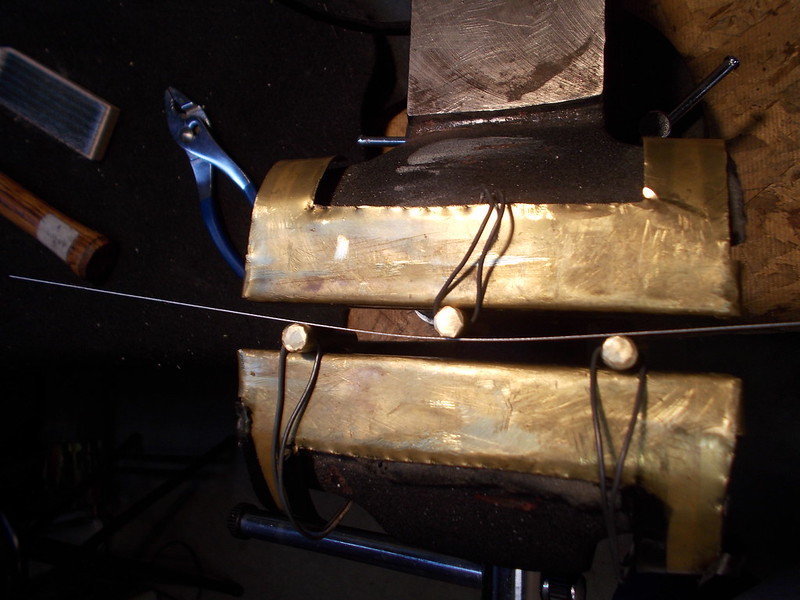

I had to get the bends relatively close first. I was using a technique I saw on the other forum. I used three brass pieces of round-stock I cut from the remainder of a brass ramrod project. Hanging them into the bench vise in various positions I needed to bend. But then I put the glued-together barrel tang assembly in place, clamped it down tight at the joint of the breech and tang, and clamped the rest down with two clamps and small pieces of wood arrow shaft so the clamps wouldn't damage the top of the inlet which allows very hard clamping to the bottom of the inlet. I filed a little flat top and bottom on the arrow pieces so they don't roll. I let it set for 24 hours and while it did try to spring back a little bit, it was such that when I clamped it down, drilled and screwed it down with the two tang screws, it came right into place. I don't know if it saved any time...maybe a little filing on top since the top level wood/metal match was basically a perfect fit.

Unfortunately I didn't take any pictures of the vice-bending process, but here's one of the vice with the bending rods in place and my flexible ruler as the metal. One just calculates the bend point needed and puts the single-side rod under the tang at that point, then positions the two rods on the other side to what seems like a good bending point and applies pressure with the vice to get a controlled bend. I had never done a long tang like this and these simple tools quickly got a fairly close bend in place.

021214 Tang Bending tools and vice process 1 by mdheaser

021214 Tang Bending tools and vice process 1 by mdheaser 021214 Tang Bending tools and vice process 2 by mdheaser

021214 Tang Bending tools and vice process 2 by mdheaser