appalichian hunter

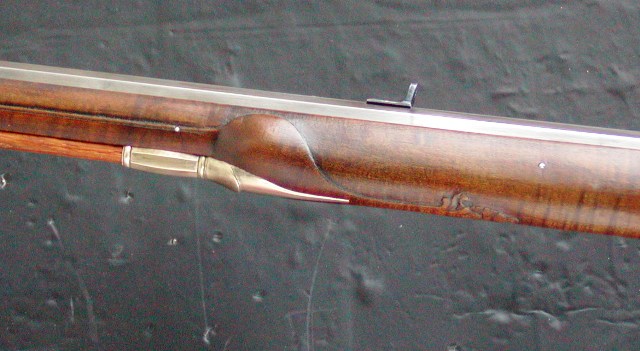

75 Cal.

- Joined

- Oct 28, 2018

- Messages

- 5,828

- Reaction score

- 9,476

I like it, very nice rifle.

Hi Rudyard,You do nice work no doubt about it .But I doubt locks where ever browned , and though I have two dogs "helping " me in my shop it's never as tidy as yours .

Regards Rudyard

Train wreck workshop! Mine is so small its a permanent tip . All these super tidy work shops astound me but at least its better than my first workshop in a cellar that periodically flooded from spring water . I worked in gum boots so the fileings fell onto them and once dry again I had red gumboots like Paddington Bear . At least any dropped parts couldn't bounce far .Its 'Reemarkable' how far a dropped part will bounce . A shy three foot drop shouldn't allow a part to bounce much but it does anyway. And its also 'Reemarkable' how fast a tidy up grows back to a jumble . When I 'wintered' in the US I took some needle files .taps & dies a few drills and the useual small carveing chisles . Most customers had the basic saws & benches with a vise & I made a good few guns on that basic plan I used to check out the flea markets for files selling for peanuts but many quite excellent . A far cry from Dave's set up but needs must.I enjoy watching you build dave, I can’t figure out how you keep your shop so clean as you work, mines a train wreck just making a horn!

Enter your email address to join: