Hisownself

32 Cal.

- Joined

- Apr 27, 2014

- Messages

- 31

- Reaction score

- 0

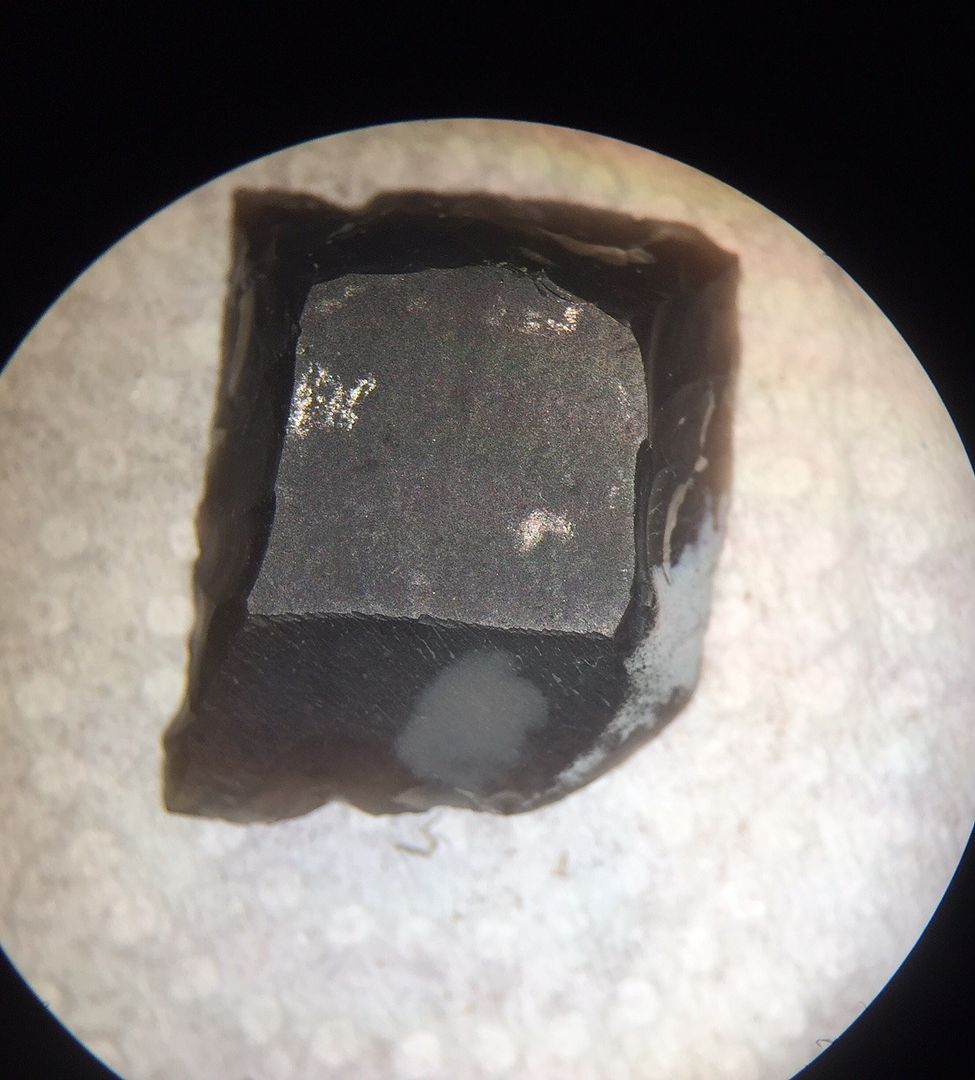

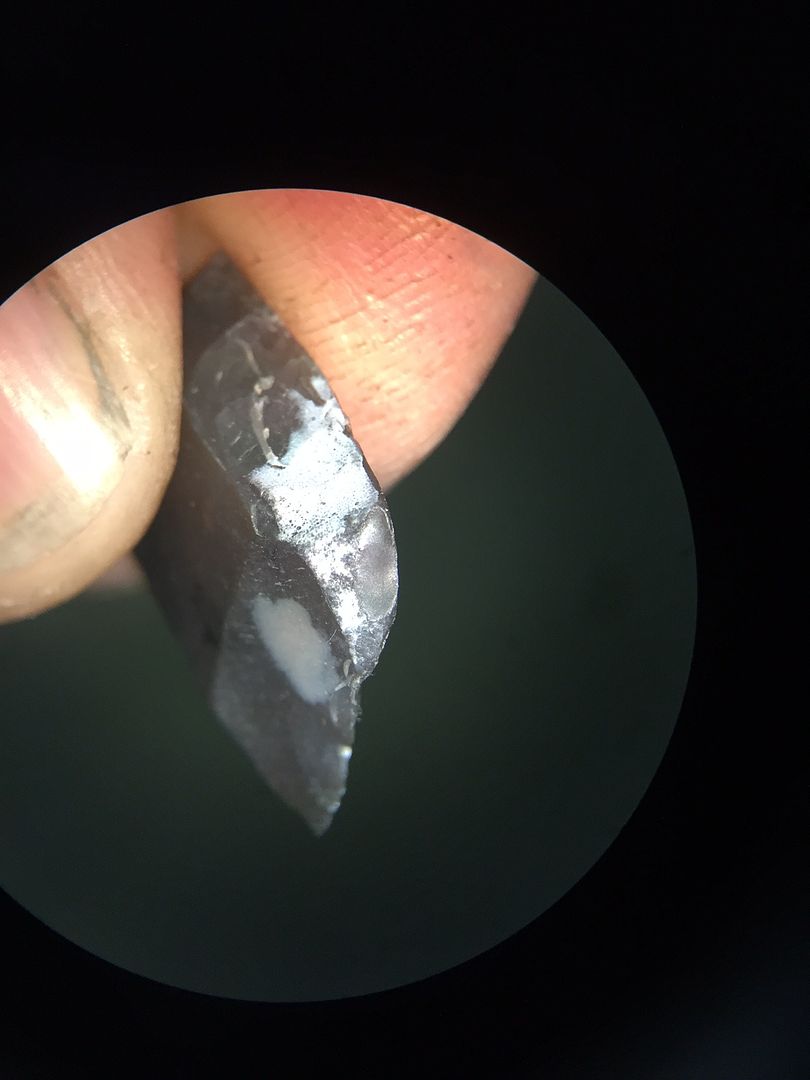

My smoothbore has an 0.065" touch hole and Davis lock. Using English flints the other day I got 45 shots without an issue, and then it wouldn't spark. I noticed the left edge of the flint melted into a glob that prevented the sharp edge from striking the frizzen so I knapped it off and it was fine.

Is it normal that the flint gets fried from the touch hole, or I have it set wrong?

Is it normal that the flint gets fried from the touch hole, or I have it set wrong?

:shocked2:

:shocked2: