Fur_Trapper

32 Cal.

- Joined

- Jan 26, 2014

- Messages

- 15

- Reaction score

- 0

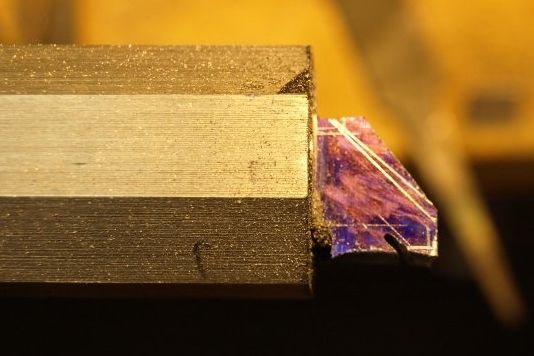

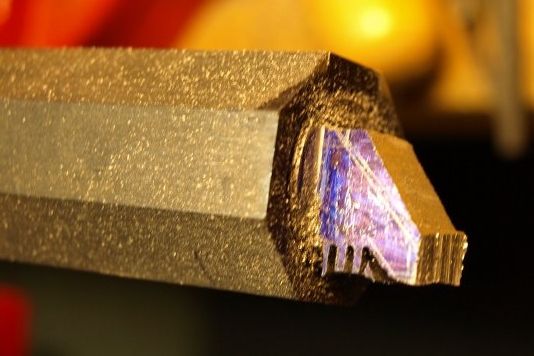

I'm curious if it would be possible to mill a pipe bung into a hooked breech plug

Tetsa Prowler said:This may seem immodest but I lifetime of owning old junk has turned me into a bit of fastener whisperer so here is my two cents.

Clamp it vertical and pour in some ATF/Penetrating oil. Every day for the next week or 3 heat the breech area with a propane torch until your smoke alarm goes off and ATF comes boiling out the vent. replenish penetrant/ATF as you breath it away.

Once you have done this for a week or five clamp it up real well in your vice, put a 2-3 foot extension on your 'perfectly' fitting wrench and twist it out of there.

For that thing that is threaded into the barrel it will come out.

Well worth trying to preserve as much of the barrel as possible.

EDIT just had a thought maybe check and make sure the vent liner is not interfering with the breech plug.

Enter your email address to join: