S.kenton said:

I havn't been shooting BP as long as some on this forum. I have, however, been shooting long enough and been around enough BP firearms ( mostly percussion) to know that it's normally NOT the firearms fault. I would guess that someone tampering with the breech plug, nipple installed incorrectly, using the wrong powder...stuff like that, causes many rumors to circulate and make the Factory made M'lers look bad in some cases. I'm sure there have been incidents that the factory was in the wrong..but I'd say that's fairly rare.

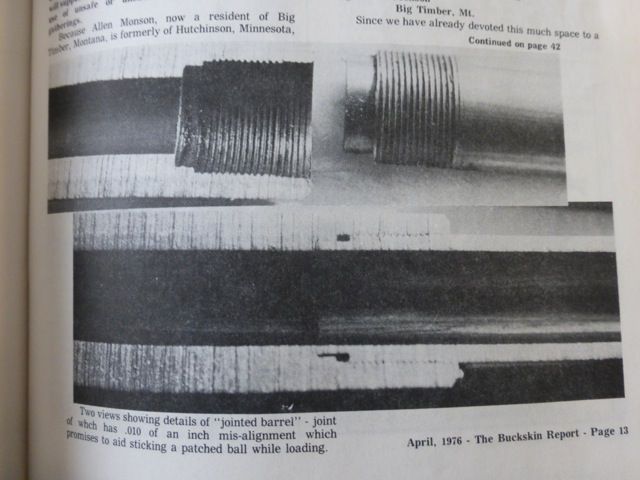

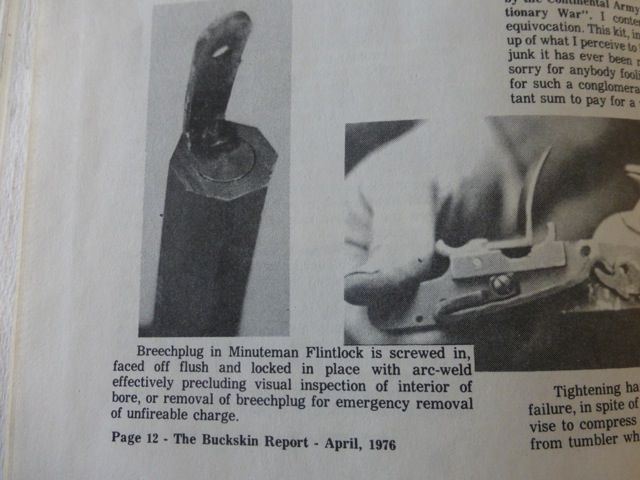

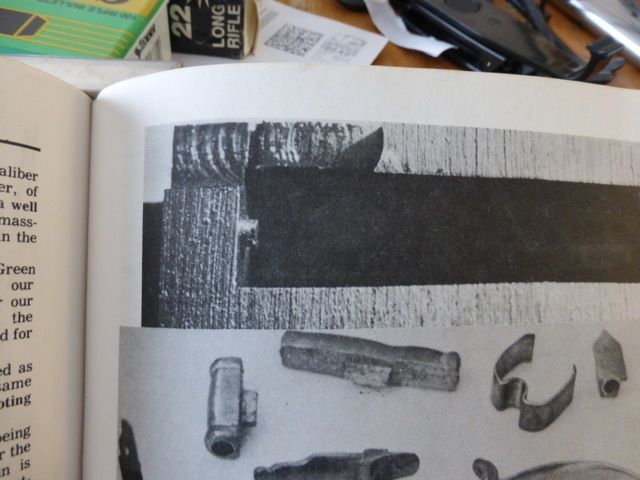

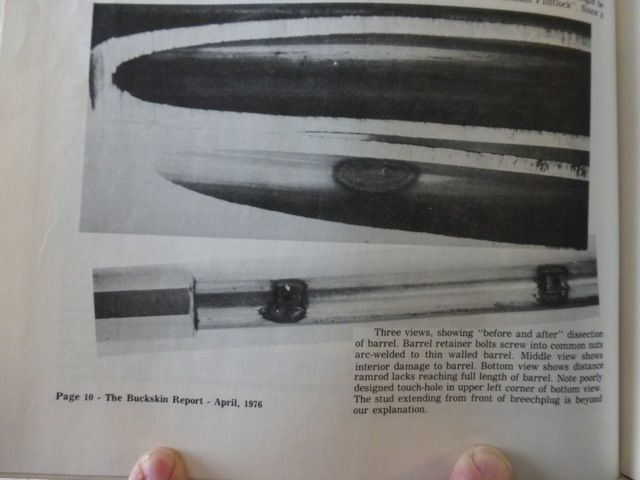

While this may be true of guns made with actual barrel steel. I.E. steels approved for gun barrels by steel makers, metallurgists and engineers, it is NOT the truth when marginal materials are used and there are a lot of unsuitable barrels out there. Some have failed...

There was a rash of failures of early TCs. These stopped like flipping a switch. This tells me there was a material change. I am SURE the buyers did not suddenly become enlightened.

Poor quality materials can fail at pressures far under the "tensile" due to very poor resistance the shock and internal pressure. "Poor hoop strength" is the term I have read in articles written by a metallurgist.

Other than the old "Buckskin Report" NO magazine has even printed ANYTHING about this. Its bad for business since it irritates advertisers. Being a resident of the small town where the Buckskin Report was published and being a friend of all the principles I can tell you that TELLING THE TRUTH is what killed the magazine. Its shame to since they would print things nobody else would touch. Kinda like "Consumer Reports" for BP shooters. Reports of blowups came in regularly. Often with new stories and photos.

Now of course nobody wants to hear it since lots of people shoot guns with deficient barrels from the metallurgical standpoint and often there are problems with the breeching as well. Both problems could be called "endemic".

I know barrel makers who describe these deficient barrels are "pipe bombs".

But ML shooters are notoriously cheap. They will buy cheap over quality about 95% of the time. Worse it is impossible to educate them since they are all experts. Since a barrel made of the gold standard for gun barrels (4150, the military started using it about the time WW-II started) will cost significantly more than one made of leaded screw stock, the "experts" will choose the 12L14 barrel.

BTW there are recorded instances of people successfully (no kaboom other than muzzle blast) shooting smokeless (how I could not say) and "duplex loads" from TCs. Then there were the the unexplained explosions with BP.

Another thing at BP pressures and velocities a short started projectile ANYWHERE in the bore should at worst BULGE the barrel. It is bursts its poor steel. But of course the experts thing a short started ball with blow a barrel. And it will if the barrel is a brittle, unsuitable steel. 4150? I have had a Garand barrel for a time shot with a plug of dirt about 2" behind the front sight. Bullet impacted at about 2600 at least. Bulged the barrel. It was shot for years afterwards. Why would a low pressure, low velocity load shatter a GOOD barrel?

Rings are the norm in modern firearms with bore obstructions (unless 416 stainless) but people expect MLs to "break". Why is this the case?

Dan