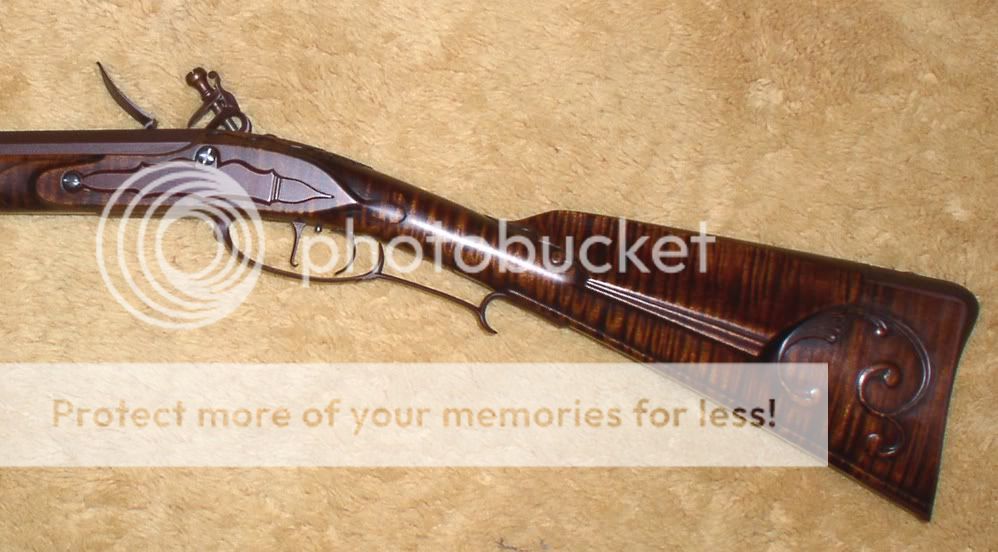

One of the most enjoyable and easy tasks of building a LR, is the sideplate. The only times I've used purchased sideplates are w/ parts sets that have the sideplate already inlet. Before buying the first Chambers' parts set, I asked Jim if NOT inletting the sideplate was possible. He said he could supply that but then the warranty would be void. So....I bought the "kit" and found out that the premarked holes in the sideplate and the inlet caused RR interference w/ the front lockbolt. If the front lockbolt location wasn't according to the "Premark", the bolt head location looked off center.

Making a sideplate that looks like it belongs in the panel is easy and here's how I do it. Of course my way isn't the only way, but it does work.

After the lockbolt holes are drilled, a 1/8" thick brass plate is clamped to the sideplate panel and the same drills have a "centerpunch" ground on the shank end. The 2 prickpunches are made using the 2 lockbolt holes.

The portion of the sideplate between the rear lockbolt hole and the front lockbolt hole is predetermined, but the rear portion of the sideplate should have the sideplate "tail" centered w/ the beavertail point of the lock panel. To accomplish this is easy and just takes a few sketches and it's done....always referring back to the rear lockbolt hole.

Another important feature of a sideplate is how well its long , bottom edge coincides w/ the bottom contour of the sideplate panel. Of course this is done in conjunction w/ the design for centering the sideplate "tail".

Some sideplates of the original builders didn't fit well w/ the panel and were more or less a utilitarian washer for 2 bolts....but, why not make if both a "washer" and an aesthetic feature?

Like I said...there are no doubt other ways to make an aesthetically pleasing sideplate that looks like it belongs...the above is just one way.....Fred

Making a sideplate that looks like it belongs in the panel is easy and here's how I do it. Of course my way isn't the only way, but it does work.

After the lockbolt holes are drilled, a 1/8" thick brass plate is clamped to the sideplate panel and the same drills have a "centerpunch" ground on the shank end. The 2 prickpunches are made using the 2 lockbolt holes.

The portion of the sideplate between the rear lockbolt hole and the front lockbolt hole is predetermined, but the rear portion of the sideplate should have the sideplate "tail" centered w/ the beavertail point of the lock panel. To accomplish this is easy and just takes a few sketches and it's done....always referring back to the rear lockbolt hole.

Another important feature of a sideplate is how well its long , bottom edge coincides w/ the bottom contour of the sideplate panel. Of course this is done in conjunction w/ the design for centering the sideplate "tail".

Some sideplates of the original builders didn't fit well w/ the panel and were more or less a utilitarian washer for 2 bolts....but, why not make if both a "washer" and an aesthetic feature?

Like I said...there are no doubt other ways to make an aesthetically pleasing sideplate that looks like it belongs...the above is just one way.....Fred