You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Double barrel shotgun

- Thread starter Squirrel79

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Pull off of the barrels and take some pics of the proof marks on the underside of the barrel. Without seeing the proofs it’s all just guessing.

Yes, better pictures would most certainly help! Like there is a name of "T. C. Montxxxxx" on the lock, but that's all I can read from your photo.

Nice '1/2-pistol' grip stock design, usually found on higher grade sporting arms. I like it!

Nice '1/2-pistol' grip stock design, usually found on higher grade sporting arms. I like it!

Squirrel79

32 Cal

I shot it with 50 grains of blackpowder and 50 grams of lead shot. It shot good. The last 2 photos you can see a gap in the barrel that worries me. Is that normal or does it need to be filled in with solder?

Attachments

- Joined

- Sep 20, 2010

- Messages

- 1,206

- Reaction score

- 1,230

It looks like its just the breech plugs, they wouldnt be soldered together.

I think I would be worried. Looks like they are separating. Just my opinion. I'm sure you are going to get a whole lot more.

If the ribs are tight and the barrels ring when suspended off a string and tapped, they should be good.

The breeches look like someone gave them a rough time dismounting them.

They aren't meant to be joined as they are meant to be removable,( under very rare conditions).

The barrels are English and the bore is 13, so a 12 gauge in reality.

Guns this size often shoot very well with your present powder charge, and an ounce of shot.

The breeches look like someone gave them a rough time dismounting them.

They aren't meant to be joined as they are meant to be removable,( under very rare conditions).

The barrels are English and the bore is 13, so a 12 gauge in reality.

Guns this size often shoot very well with your present powder charge, and an ounce of shot.

Sometimes a well-meaning fellow will try to re-solder old double barrel guns and end up with two loose barrels. Joining barrels properly has always been an art form. There should be no physical gap between a side-by-side gun's barrels. None.

Damascus , by its very nature, bears exam by a qualified gun expert if one intends to give the old girl repeated outings. Shotgun loads are always "Volume to Volume", not by weight starting out.

Damascus , by its very nature, bears exam by a qualified gun expert if one intends to give the old girl repeated outings. Shotgun loads are always "Volume to Volume", not by weight starting out.

Squirrel79

32 Cal

I never thought about that. I'm fairly certain you may be correct. The barrels are only like that at the breech. Everything else looks great and is tight.It looks like its just the breech plugs, they wouldnt be soldered together.

Squirrel79

32 Cal

If the ribs are tight and the barrels ring when suspended off a string and tapped, they should be good.

The breeches look like someone gave them a rough time dismounting them.

They aren't meant to be joined as they are meant to be removable,( under very rare conditions).

The barrels are English and the bore is 13, so a 12 gauge in reality.

Guns this size often shoot very well with your present powder charge, and an ounce of shot.

Squirrel79

32 Cal

They are tight everywhere else and do ring. It's only at the breeches they're like that. I never considered being able to remove the breech plugs. This is the first sxs I've owned. So since they're English barrels does it need metric thread nipples?

Yes, to above post. Barrels are solder and then BP are screwed in, and they should be indexed to barrel (line). If they ring true, I'd use it. I find a good load to start with in the 12 bore. Is a 45/70 brass case loaded equal amounts of powder and shot. V.M. Star recommended.

- Joined

- Mar 23, 2021

- Messages

- 2,834

- Reaction score

- 6,063

Same advice, if the barrels ring, put a small single cell flashlight or similar down the barrels and look for huge pits, if there are none, get to shooting.

The gap between the breech plugs is larger than most but they are independent of each other.

The gap between the breech plugs is larger than most but they are independent of each other.

- Joined

- Aug 6, 2005

- Messages

- 7,094

- Reaction score

- 5,386

They are tight everywhere else and do ring. It's only at the breeches they're like that. I never considered being able to remove the breech plugs. This is the first sxs I've owned. So since they're English barrels does it need metric thread nipples?

The English-made sporting gun with metric threads has yet to be made. You may have noticed that shotgun barrels are in gauges of so many spherical shot to the pound - 12 gauge [aka 12 bore] is the measure here, not 18mm or thereabouts.

A token nod to the metric system suffices here in UK, and even the government of the day gave up trying to fully metricate the UK back in the 80's. We use miles and yards for distances here, except for Wales, which uses Milltir and Llathau. We do miles per gallon, too, seeing no sense in measuring how many litres it requires for us to travel a metric distance, when our distances are measured in miles.

Bows have draw weights in pounds, and arrows are measured in inches. Powder is measured in grains, as are bullets, and velocities in feet per second. Flying is measured in MPH and so many feet above ground or sea level - and tides are measured in feet, as are winds.

You get the idea, I hope.

Mr T Foley,

Its very good to know things have not changed.

Its decades since we left the UK, but comforting to know a lot is still the same.

I was however, foxed by the modern shot loads for cartridges I read about when looking up sporting clays!

grams and all that!

I was used to Eley Grand Prix, Impax, or Hull Cartridge company. offerings in ounces.

Sherrif John,

Many old guns shoot best with a load that are not volume for volume.

English powder flasks were marked in drams, and shot flasks marked in ounces.

as I said, a good killing pattern can be produced with the old rule of thumb, a dram to a half ounce, so two drams, (about 55 grains) to an ounce of shot.

Best,

R.

Its very good to know things have not changed.

Its decades since we left the UK, but comforting to know a lot is still the same.

I was however, foxed by the modern shot loads for cartridges I read about when looking up sporting clays!

grams and all that!

I was used to Eley Grand Prix, Impax, or Hull Cartridge company. offerings in ounces.

Sherrif John,

Many old guns shoot best with a load that are not volume for volume.

English powder flasks were marked in drams, and shot flasks marked in ounces.

as I said, a good killing pattern can be produced with the old rule of thumb, a dram to a half ounce, so two drams, (about 55 grains) to an ounce of shot.

Best,

R.

The half pistol grip was generally seen on continental guns. British guns more often had straight grips.Yes, better pictures would most certainly help! Like there is a name of "T. C. Montxxxxx" on the lock, but that's all I can read from your photo.

Nice '1/2-pistol' grip stock design, usually found on higher grade sporting arms. I like it!

Damascus has been used in blades to good effect for 11 centuries. It is clearly a mature and well understood technology. I love the patterns in the steel of Damascus guns, and given the approval of the rare qualified expert, would not hesitate to use a Damascus barreled gun.Sometimes a well-meaning fellow will try to re-solder old double barrel guns and end up with two loose barrels. Joining barrels properly has always been an art form. There should be no physical gap between a side-by-side gun's barrels. None.

Damascus , by its very nature, bears exam by a qualified gun expert if one intends to give the old girl repeated outings. Shotgun loads are always "Volume to Volume", not by weight starting out.

An amateur attempting to re-solder double barrels is indeed a script for disaster. Not only do the barrels need properly joined, they also must be regulated.

There are three main reasons for the space between the breech plugs first is this gun has been shooting heavy loads the regulated load for a 12 bore is 2.3/4 drm of black powder to 1.1/8oz of shot ,second there has or still is a space between the hooks of the breech and the openings of the standing breech, the photo tells that this has happened Last is the regulating breech flats have eased and a build up of rust has formed, just stick with the proper load it may not move further but if the ribs show signs of lifting then the barrels will have to be stripped and soldered

The nipples are standard 1/4 BSF or 9/16 BSF if any larger is give away that heavy loads have been used.This is a common fault with muzzle loading shotguns through neglect which i have come across and put right many times

Feltwad

The nipples are standard 1/4 BSF or 9/16 BSF if any larger is give away that heavy loads have been used.This is a common fault with muzzle loading shotguns through neglect which i have come across and put right many times

Feltwad

- Joined

- Aug 6, 2005

- Messages

- 7,094

- Reaction score

- 5,386

Dear All - please don't confuse 'Damascus' barrels with 'fine twist' barrels - they are quite different in manufacture.

Damascus Barrels - Barrel tubes built up by twisting alternate strips of iron and steel around a fixed rod (mandrel) and forge-welding them together in varying combinations according to the intended quality and the skill of the maker. The rod was withdrawn, the interior reamed and the exterior draw-filed until the finished tube was achieved. Damascus barrels may be recognized by any of a variety of twist or spiral patterns visible in the surface of the steel. Before the 20th century, barrels were typically built in this manner because gunmakers did not have the technology to drill a deep hole the full length of a bar of steel without coming out the side. Generally superseded a century ago by fluid steel barrels.

Damascus barrels were usually intended for use with black powder---the standard of the day. The contour of the barrel wall thickness, intended for the fast explosion of black powder, was quite thick at the breech and tapered thinner towards the muzzle. It is not advisable to shoot modern smokeless powder in a damascus barrel. Apart from giving due deference to the age of such barrels and to the method of their construction, smokeless powder burns more slowly, lowering the pressure at the breech end, but considerably raising it further down the barrel to a level such barrels were rarely designed to handle.

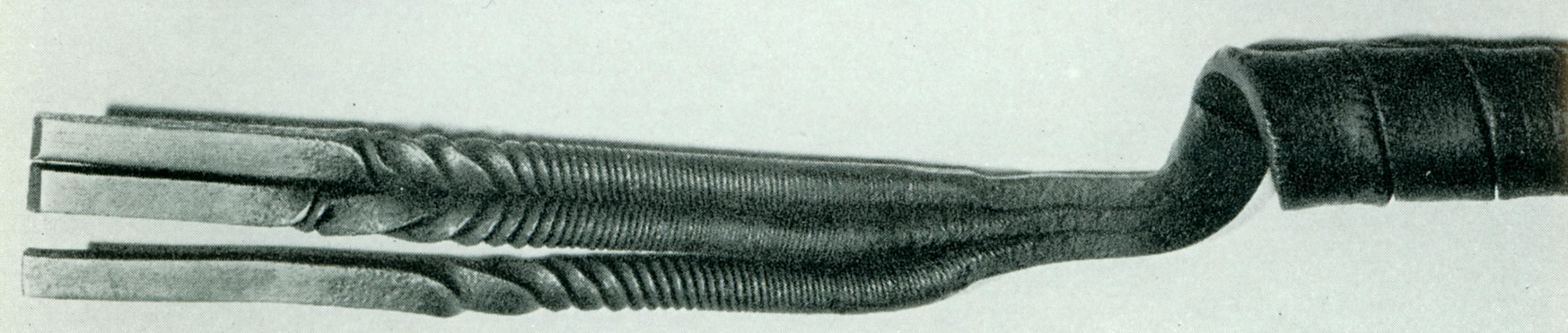

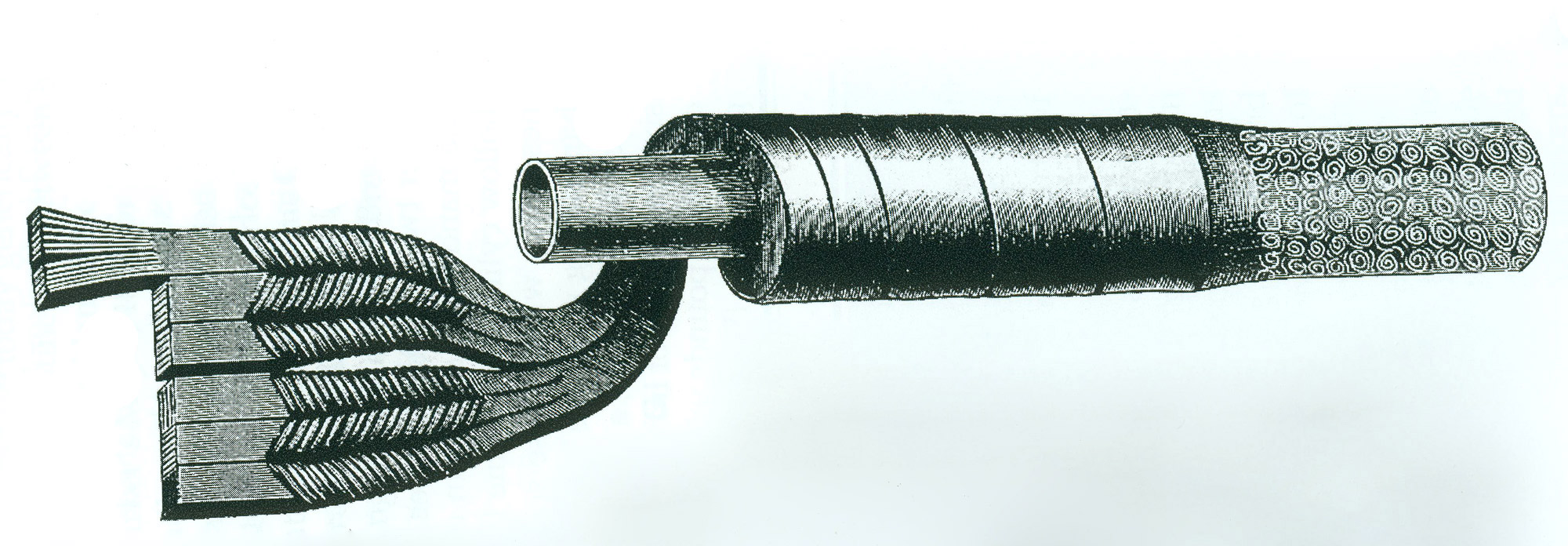

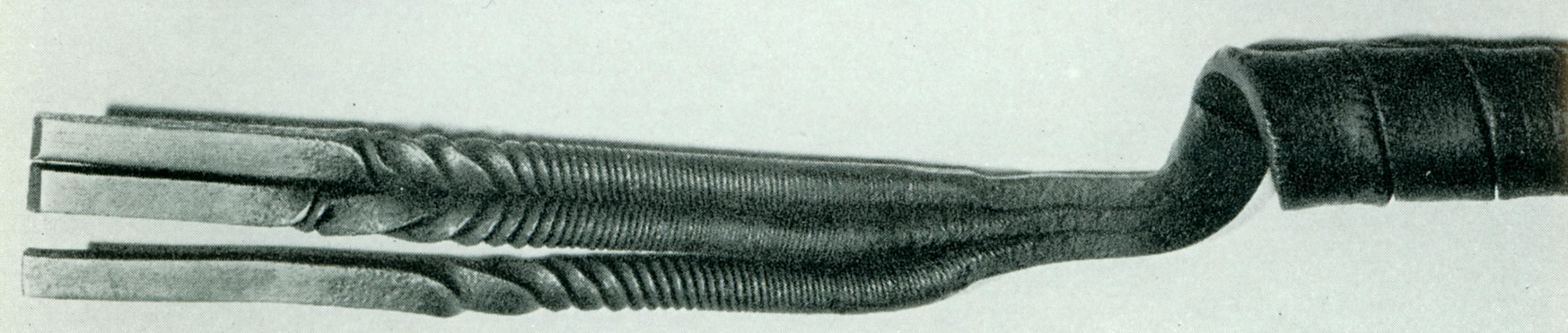

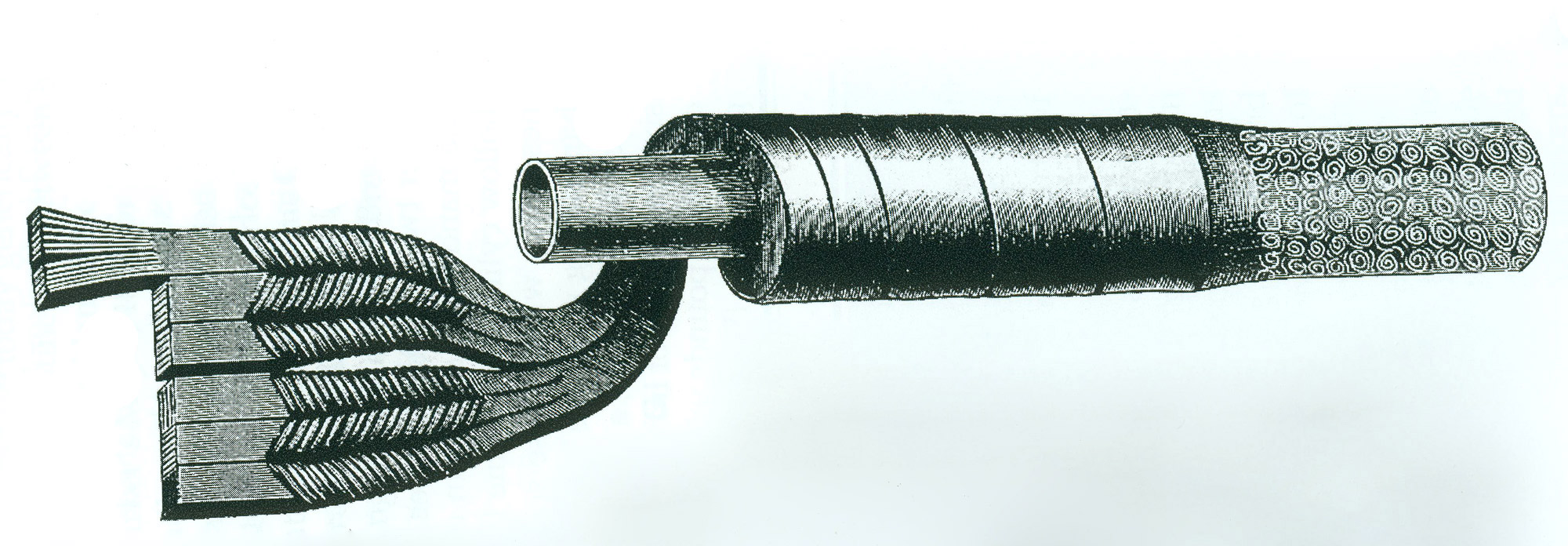

A demonstration forging, showing the steps undertaken to construct a barrel tube of damascus steel. In this case, three bars, usually of different alloys, independently twisted, then forge-welded together at a bright yellow heat into a single continuous flat bar, then wrapped around a mandrel and further forge-welded into a solid spiral. From Richard Akehurst, Game Guns & Rifles, G. Bell & Sons, London, 1969.

And, finally, bored out inside, drawfiled outside to requisite thinness, and finished to enhance the forged pattern.

I'm sure that Feltwad or Old Dog will come by dreckly and explain all this to you.

Damascus Barrels - Barrel tubes built up by twisting alternate strips of iron and steel around a fixed rod (mandrel) and forge-welding them together in varying combinations according to the intended quality and the skill of the maker. The rod was withdrawn, the interior reamed and the exterior draw-filed until the finished tube was achieved. Damascus barrels may be recognized by any of a variety of twist or spiral patterns visible in the surface of the steel. Before the 20th century, barrels were typically built in this manner because gunmakers did not have the technology to drill a deep hole the full length of a bar of steel without coming out the side. Generally superseded a century ago by fluid steel barrels.

Damascus barrels were usually intended for use with black powder---the standard of the day. The contour of the barrel wall thickness, intended for the fast explosion of black powder, was quite thick at the breech and tapered thinner towards the muzzle. It is not advisable to shoot modern smokeless powder in a damascus barrel. Apart from giving due deference to the age of such barrels and to the method of their construction, smokeless powder burns more slowly, lowering the pressure at the breech end, but considerably raising it further down the barrel to a level such barrels were rarely designed to handle.

A demonstration forging, showing the steps undertaken to construct a barrel tube of damascus steel. In this case, three bars, usually of different alloys, independently twisted, then forge-welded together at a bright yellow heat into a single continuous flat bar, then wrapped around a mandrel and further forge-welded into a solid spiral. From Richard Akehurst, Game Guns & Rifles, G. Bell & Sons, London, 1969.

And, finally, bored out inside, drawfiled outside to requisite thinness, and finished to enhance the forged pattern.

I'm sure that Feltwad or Old Dog will come by dreckly and explain all this to you.

Attachments

Last edited:

It's a 13-gauge.

Similar threads

- Replies

- 1

- Views

- 534

- Replies

- 2

- Views

- 638

- Replies

- 11

- Views

- 830

- Replies

- 2

- Views

- 297