In summary, I found the undertaking to be an extremely interesting project, not only learning and proving/disproving some things for myself, but identifying a readily available alternative to lead PRBs if that ever becomes an issue such as a "lead free hunting zone", a "lead ban", etc.

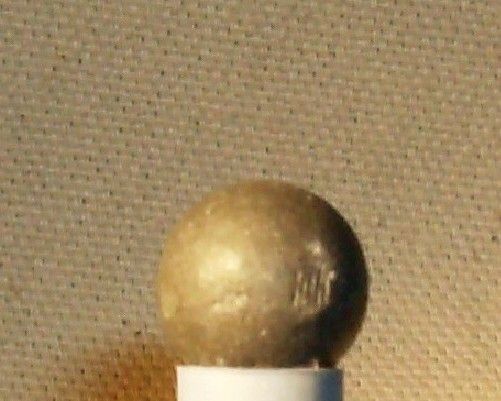

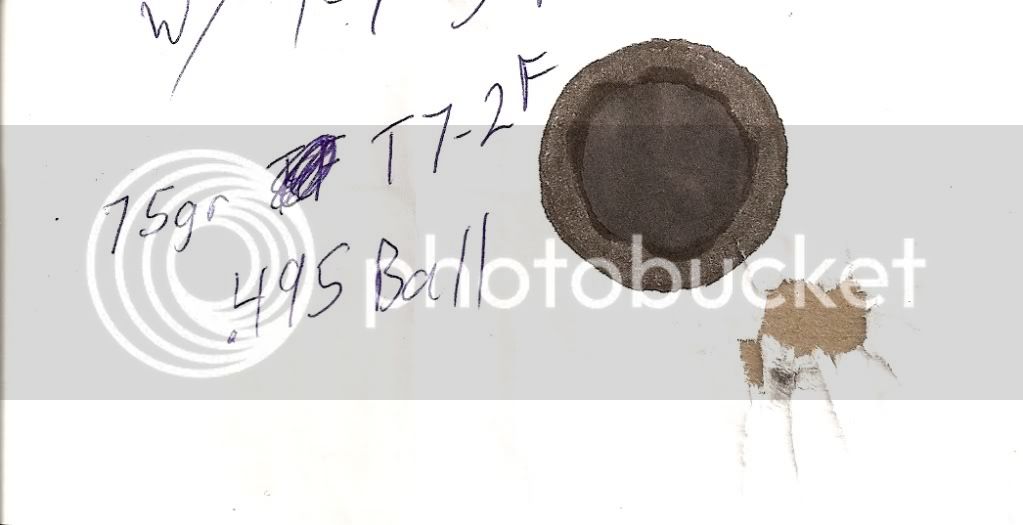

For me, the ragged hole accuracy of 9/16" solid marbles for practice, and .5625" brass balls for deer hunting...both out of my .58cal TVM Early Virginia...make the .58cal a complete performer to hang on to for a few more years.

And as with any/all tests I conduct, I share the information results as clearly as possible, at no charge to anyone.

The tests are what "I" did, with "my" equipment, "my" components, "my" supplies, my methods, "my" abilities.

There is 'no recommendation' that anyone do this...it is simply information for anyone to draw from or ignore as they fit.

:thumbsup: