Relax! I'm one to to talk but....

The sights and lugs are really the one of easiest parts of the job. Besides do not worry about that yet. You have plenty to do before you even get that far. Also you will have 3 underlugs to dove tail into the barrel. That will be great practice for the tops side sights that show.

First Get the books. Grenville County(

written in Canadian so you will have to read a sentence at least 3 time before it...clicks), Shumways Recreating the American Long Rifle. Dixon's Art of the Pennsylvania Longrifle. The Dixon book is about 20 bucks. If you can swing it I also recommend Shumways Rifles in Colonial America series for study. I wish I had them.

Next if you have a Dremel or other rotary tool, throw that joker as far as you can. It may be better to lock it in a box and throw the key as far as you can. :wink: The only power tool you'll really need is a drill. A drill press would be great and needed but you can get by with a handrill if you have to and if you are very very careful.

Must haves....

A solid work bench, You are going to find out rifle building is hard work a sturdy work bench is a must. Preferably bolted to the floor and wall.

Lighting, not just overhead...overhead and adjustable is great...even a adjustable desk lamp is better than just overheads.

Helps to have a layout area, The kitchen table is a bit%^.

A heavy Bench vise bolted to the work top. You have to have one to hold the work securely. I actually had two on my bench a good one and a cheap one. That way I could hold the barrel/stock in two points.

The good bench vise was my platform for the file work. Do not forget the padding for the jaws.

A big honking adjustable wrench for the breech plug. I use an antique steam wrench also known as a monkey wrench.

This is not a pipe wrench. It does not have the slack in the jaws like a pipe wrench also the jaws are smooth a pipe wrench will not work. This old wrench has just enough slack in the jaws to clap down on the breech plug with solid contact with little danger if slipping. Some use smaller versions of this, some use crescents ground to fit, others use a home made breech wrench. It's a good idea to have good solid contact and even some brass shims to protect the work.

You will have to remove the plug several times during the build.

You will need these three cutting tools IMHO a 1/4" bench chisel, a 1/2" Bench chisel and a gouge just slightly smaller than the curve of the lock nose.

You need a driver, either a chisel mallet or equivalent. I use an wooden old tool handle.

You will need to know how to sharpen these tools and keep them sharp with a quality stone and strop. This is very very important.

Avoid a set, most of them you will not need. IMO avoid palm chisels. Buy good quality tools. I use Stanley Sweet hearts. Forget ACE, Lowes, Home Depot as they do not have the quality you need..

You need an exacto type knife.

You need a 48" ruler or straight edge, a dry wall rule works well.

You need inside and out side calipers, need not be expensive. Mine are plastic elcheapos.

My mind is blank but this square...

Some good selection of files. Including a safe sided triangle file for those dovetails. I find a good rattail is needed for shaping. These files,straight, bastard, round will be your must used tools, old new just make sure they are good.

Good rasps like a cabinet makers rasp. Stanley sure forms ect.

Chalk for files. File brush

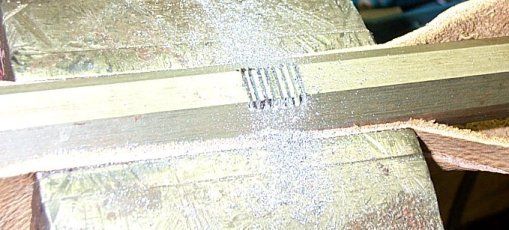

Needle files, sometimes you need a very good file to start the groove for your hack saw.

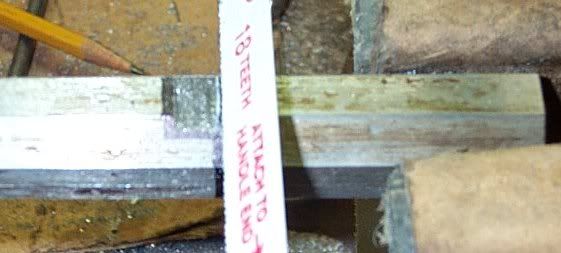

A very good hacksaw with good blades.

Fingernail files IE pop cycle stick emery, can be cut to shape.

Inlet black some use candle soot, Prussian Blue, lipstick and Sharpie markers...what ever works for you.

Drills, countersinks and taps for your bolts and screws.

A selection of good quality sand paper unless you are going full 18th Century then you need a goodly selection of scrapers. Do not forget backing for the paper.

Lock vice to disassemble lock.

Lastly and most importantly patience and perseverance.

I'll go ahead and mention this...a good storage place in case life gets in the way. Pipe busted basement flooded, I had to dismantle and store my rifle, have yet to get set back up. So if the worst happens be prepared.

Skill advice.....

When you have your stuff set up. Buy some blocks of wood. Take your lock apart file it clean it up, inlet it into those blocks of wood using your new tools. Could do the same with the barrel breech. Be patient when you get the hang of things, start on your rifle.

Most Nobody does this but it is good advice.

The books will have detailed tool lists. You may want a back saw, or jewlers saw, if carving you may want some scratch stocks and a bigger selection of chisels. The above is not counting optional home made purpose tools.