Goldhunter

54 Cal.

- Joined

- Mar 27, 2006

- Messages

- 1,596

- Reaction score

- 6

So after building my 2 flintlock rifles I decided I wanted to try my hand at a pistol.

I met Ryan Roberts from MBS at a winter camp/ shoot last January and talked parts, thoughts, likes/dislikes, and recommendations with him. I settled on 28ga (.54 cal) so this could be a companion piece to my Dickert rifle. I also wanted a smoothy for shot. Grouse are plentiful here and often give a close shot if you do your part. :grin:

A month or so later I contacted Ryan and ordered an 7.5” octagon to round barrel in 28ga and one of his stocks. The lock is a Chambers small siler I did a slight mod to. The trigger guard I ordered from TOTW (I think). Each build I’ve tried something new and I wanted to try my hand at making as much of this as I could. So this time I made the side plates, thimbles, barrel underlugs, trigger and plate; the trigger/ trigger plate being the parts I’ve not tried making before. :grin: Not too bad for a first go I think.

I also decided to add a cow horn tip to the rammer. I made a small front sight for this but decided at the last minute to not use it. It can be added in the future if I really need it as the barrel was cold blued (easy touchup).

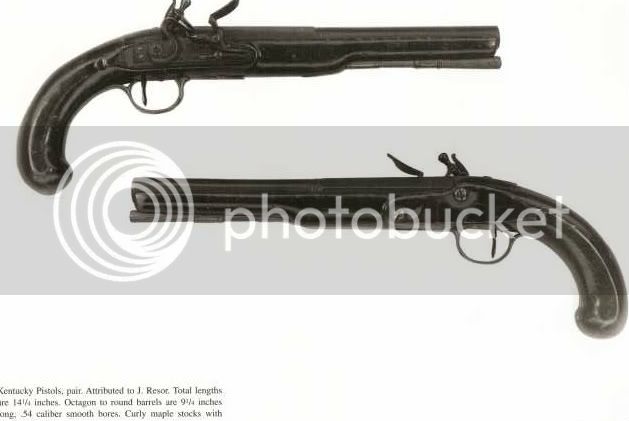

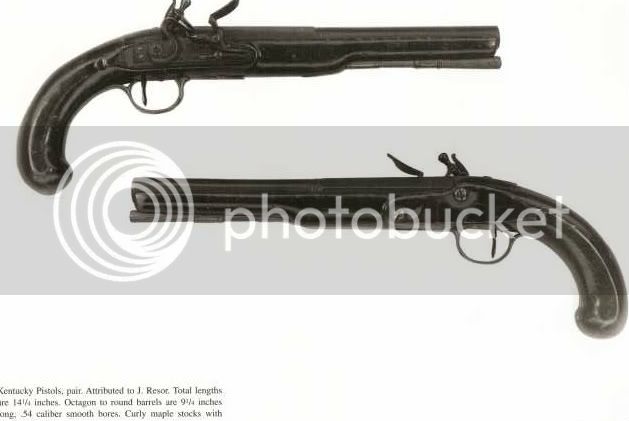

I also wanted a very simple pistol. I wanted to get the shape/form down first before I tried any carving on a pistol. I found a pistol to base this one off in the book Accouterments II by James R. Johnston. The pistol was by J. Resor.

The stain is Ferric Nitrate using denatured alcohol for dissolve the crystals. A thinned sealer coat and couple thicker coats of a Seedlac violin varnish Eric Kettenburg wrote about in MuzzleBlasts years ago followed. I used this same varnish on my .50 Lehigh I made a couple years ago and liked it. The final finish is rubbed in oil (linseed I boiled myself as per a recipe I found on here somewhere I think).

Lessons learned. :cursing: I got a bit heavy handed with the scraper in a couple places and had to go back touch up the entry thimble and one of the side plates (they were now sitting a skosh proud). The varnish dries quick and it can be a bugger to knock the high spots off without damaginge the finish below so some areas don't appear as smooth as others. I need to work on a better way in the future (good thing I have somemore maple scraps). I still need to work on my soldering. It's not as clean as I'd like.

My pictures aren’t the greatest, my apologies. :wink:

Here is the original.

And mine.

A couple I took with more sun to try to get the grain to show more.

Any thoughts or suggestions for next time?

Now, to take apart that horrible Traditions percussion I put together years ago and redo it. :rotf:

Thanks for looking.

I met Ryan Roberts from MBS at a winter camp/ shoot last January and talked parts, thoughts, likes/dislikes, and recommendations with him. I settled on 28ga (.54 cal) so this could be a companion piece to my Dickert rifle. I also wanted a smoothy for shot. Grouse are plentiful here and often give a close shot if you do your part. :grin:

A month or so later I contacted Ryan and ordered an 7.5” octagon to round barrel in 28ga and one of his stocks. The lock is a Chambers small siler I did a slight mod to. The trigger guard I ordered from TOTW (I think). Each build I’ve tried something new and I wanted to try my hand at making as much of this as I could. So this time I made the side plates, thimbles, barrel underlugs, trigger and plate; the trigger/ trigger plate being the parts I’ve not tried making before. :grin: Not too bad for a first go I think.

I also decided to add a cow horn tip to the rammer. I made a small front sight for this but decided at the last minute to not use it. It can be added in the future if I really need it as the barrel was cold blued (easy touchup).

I also wanted a very simple pistol. I wanted to get the shape/form down first before I tried any carving on a pistol. I found a pistol to base this one off in the book Accouterments II by James R. Johnston. The pistol was by J. Resor.

The stain is Ferric Nitrate using denatured alcohol for dissolve the crystals. A thinned sealer coat and couple thicker coats of a Seedlac violin varnish Eric Kettenburg wrote about in MuzzleBlasts years ago followed. I used this same varnish on my .50 Lehigh I made a couple years ago and liked it. The final finish is rubbed in oil (linseed I boiled myself as per a recipe I found on here somewhere I think).

Lessons learned. :cursing: I got a bit heavy handed with the scraper in a couple places and had to go back touch up the entry thimble and one of the side plates (they were now sitting a skosh proud). The varnish dries quick and it can be a bugger to knock the high spots off without damaginge the finish below so some areas don't appear as smooth as others. I need to work on a better way in the future (good thing I have somemore maple scraps). I still need to work on my soldering. It's not as clean as I'd like.

My pictures aren’t the greatest, my apologies. :wink:

Here is the original.

And mine.

A couple I took with more sun to try to get the grain to show more.

Any thoughts or suggestions for next time?

Now, to take apart that horrible Traditions percussion I put together years ago and redo it. :rotf:

Thanks for looking.