- Joined

- Nov 26, 2005

- Messages

- 5,265

- Reaction score

- 11,134

Hi,

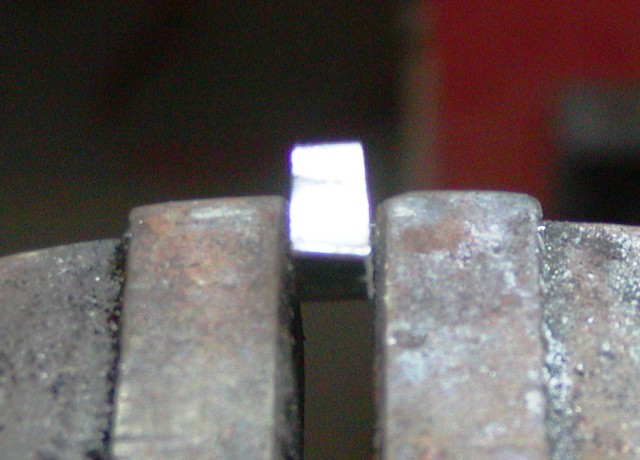

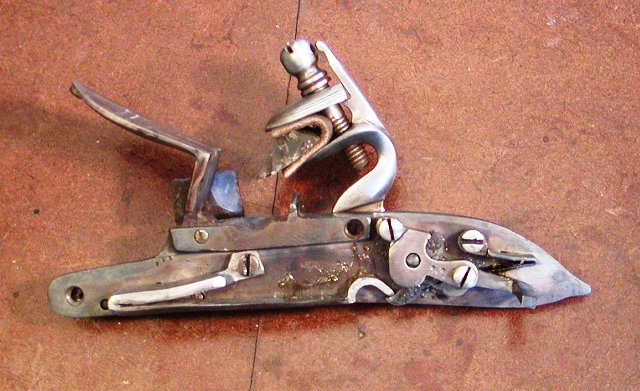

And now the first India-made lock and gun. The "fusil de chasse". The shoulder on the post on the tumbler does not protrude far enough above the lock plate so the cock scrapes against the plate.

You can see the dished out tumbler hole and the scraping of the cock against the plate.

The gun suffers from an excessive trigger pull probably over 11 lbs. One reason is the sear spring in completely collapsed with virtually no movement possible.

It is very heavy plus the full cock notch is angled such that the sear has to push the tumbler forward against the mainspring to release it from full cock.

This is of course complete junk. Next, look at the bend in the sear screw.

It is also not drilled perpendicular to the lock plate. Now look at the bends in frizzen pivot screw and feather spring screw.

Worse, look at the angle the frizzen pivot screw was drilled.

We cannot fix that because there is no extra metal to fit a larger screw and the hole in the frizzen is drilled at the same angle. We cannot fix this stuff without the work costing much more than the gun is worth. We will get the lock working as best we can and leave it at that. The India made Bess lock is the same story.

dave

And now the first India-made lock and gun. The "fusil de chasse". The shoulder on the post on the tumbler does not protrude far enough above the lock plate so the cock scrapes against the plate.

You can see the dished out tumbler hole and the scraping of the cock against the plate.

The gun suffers from an excessive trigger pull probably over 11 lbs. One reason is the sear spring in completely collapsed with virtually no movement possible.

It is very heavy plus the full cock notch is angled such that the sear has to push the tumbler forward against the mainspring to release it from full cock.

This is of course complete junk. Next, look at the bend in the sear screw.

It is also not drilled perpendicular to the lock plate. Now look at the bends in frizzen pivot screw and feather spring screw.

Worse, look at the angle the frizzen pivot screw was drilled.

We cannot fix that because there is no extra metal to fit a larger screw and the hole in the frizzen is drilled at the same angle. We cannot fix this stuff without the work costing much more than the gun is worth. We will get the lock working as best we can and leave it at that. The India made Bess lock is the same story.

dave