I just had another thought. If applying all of the advice offered here doesn't fix your lock, and if you have a set of number drill bits and a micrometer, check the diameter of the sear screw and using the drill bits as pin gauges, insert the drill bits into the sear screw hole in the sear, and check the clearance. I bought an L&R Manton about a year ago with such an oversize sear screw hole, that the sear would cant to one side, partially engaging the full cock and half cock notches.

The tolerance of a screw to screw hole should not exceed .005, and that is getting sloppy.

L&R casts their parts to final dimensions to reduce or eliminate machining. Unfortunately, casing screw holes to acceptable tolerances apparently isn't possible.

The difference between the screw diameter and the diameter of the sear screw hole, in the Manton, was .010. IMHO, that is waaaaayyyy to sloppy for for safe, reliable lock.

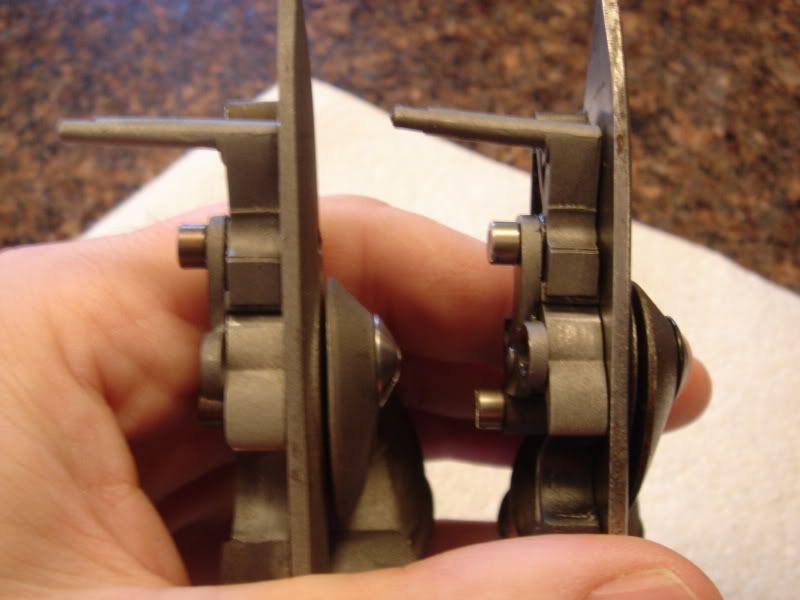

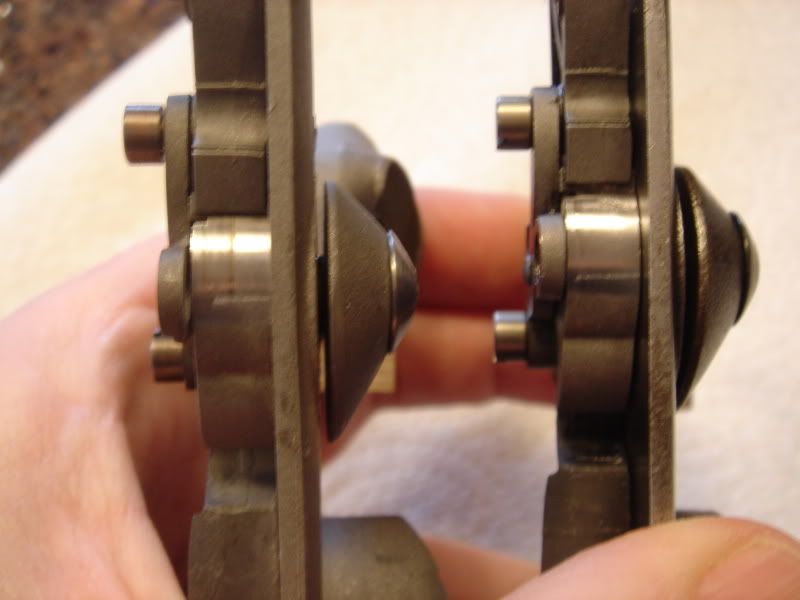

Can you post a close up photo of the sear in the assembled lock, from the bottom?

Let us know how things are going.

The tolerance of a screw to screw hole should not exceed .005, and that is getting sloppy.

L&R casts their parts to final dimensions to reduce or eliminate machining. Unfortunately, casing screw holes to acceptable tolerances apparently isn't possible.

The difference between the screw diameter and the diameter of the sear screw hole, in the Manton, was .010. IMHO, that is waaaaayyyy to sloppy for for safe, reliable lock.

Can you post a close up photo of the sear in the assembled lock, from the bottom?

Let us know how things are going.