Grand idea!Maybe do a pewter fill under that front round section of barrel. It would look kinda neat and fill in the space around the barrel.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Franken-Bubba’s Johnny Cashed carbine.

- Thread starter bubba.50

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

Did you ever try putting a complete working automobile together using Lego's? A kit rifle or pistol requires knowledge and skill also. I don't know about you, but I don't have feathers.

No, I haven't. But an automobile is not a 'one size fits all' operation like an old TC muzzleloader is. Parts from four different TC's plus a set of Davis Deerslayers fell right together to make this little carbine. Besides the triggers there's parts from a Renegade, a Hawken, a New Englander and a White Mountain carbine. Plus a 'New Englander' peep sight. And they ALL fell together 'like Legos'.

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

And while it takes some work and a very minor skill-set to complete, a TC kit goes together just as easy. Ain't nobody talkin' about what's required for a Kibler or Hawken Shop or any other of the more advanced 'kits' that are basically a pile of parts that take the skill to like I said, 'turn out these museum qulity pieces of gun art.

You gettin' bowed up in the back over nothin'.

You gettin' bowed up in the back over nothin'.

- Joined

- Mar 13, 2020

- Messages

- 7,495

- Reaction score

- 21,016

- Location

- On the Border in Idaho looking at BC

this is an example of what Bubba.50 is talking about, as far as parts going together. it started life as a plastic stocked Cabelas special.

i put it into a investarms stock while waiting for a nice TC stock to come along. it shoots so well in the IA stock it is going to stay there.

54 cal

i put it into a investarms stock while waiting for a nice TC stock to come along. it shoots so well in the IA stock it is going to stay there.

54 cal

You still had to have the skill and knowledge of what would and wouldn't fit. BTW: Nice ML!!!!this is an example of what Bubba.50 is talking about, as far as parts going together. it started life as a plastic stocked Cabelas special.

i put it into a investarms stock while waiting for a nice TC stock to come along. it shoots so well in the IA stock it is going to stay there.

54 calView attachment 88347View attachment 88348

ohio ramrod

75 Cal.

- Joined

- Aug 21, 2008

- Messages

- 7,473

- Reaction score

- 2,209

Nice work, I once made a ford-buick-mercury-lincoln- chevy car. It ran well on the drag strip but I had to sell it when money got tight. I hope you can keep your rifle and use it for a long time.

- Joined

- Mar 13, 2020

- Messages

- 7,495

- Reaction score

- 21,016

- Location

- On the Border in Idaho looking at BC

or better yet a insatiable desire to see if something will work. and the willingness to possibly fail! as my late father in law always said, "you cant make a basket if you don't shoot the ball".You still had to have the skill and knowledge of what would and wouldn't fit. BTW: Nice ML!!!!

not taking one thing from Bubba's build, just so many people today are afraid to even try something.

I totally agree with what you say. Success comes through failure.....or better yet a insatiable desire to see if something will work. and the willingness to possibly fail! as my late father in law always said, "you cant make a basket if you don't shoot the ball".

not taking one thing from Bubba's build, just so many people today are afraid to even try something.

- Joined

- Mar 13, 2020

- Messages

- 7,495

- Reaction score

- 21,016

- Location

- On the Border in Idaho looking at BC

Thomas Edison?I totally agree with what you say. Success comes through failure.....

There are a lot of quotes about success and failure..., but this wording is closest that I've found from Steve Jobs, "Success is often preceded by major failure".Thomas Edison?

But we digress..., Now lets get back to the thread

LD

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

this is an example of what Bubba.50 is talking about, as far as parts going together. it started life as a plastic stocked Cabelas special.

i put it into a investarms stock while waiting for a nice TC stock to come along. it shoots so well in the IA stock it is going to stay there.

54 calView attachment 88347View attachment 88348

Nice rifle, and in my favorite caliber. And if ML48 worked on his reading comprehension a bit he could see I totally agreed with him when I told the guy who said he admired my work that instead of admiring the work of a shade tree mechanic/parts changer he should admire/emulate/follow the master craftsmen on the gun builder's page who take a plank, a barrel, some rough castings and turn out rifles that are truly works of art. But it's easier for some to find fault I guess.

And nothing away from your gun or abilities, about the only 'skill & knowledge' involved in either of our projects is reasonably good eyesight, 'skill' to operate a straight screwdriver of proper size, and the 'knowledge' to pull the ramrod before lifting the barrel from the stock.

- Joined

- Jan 31, 2009

- Messages

- 13,055

- Reaction score

- 7,310

Too cool.

Thanks for posting.

Thanks for posting.

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

Maybe do a pewter fill under that front round section of barrel. It would look kinda neat and fill in the space around the barrel.

Says a man who's never seen me around anything liquid, especially liquid metal. LOL But it would look better.

Wildrangeringreen

40 Cal

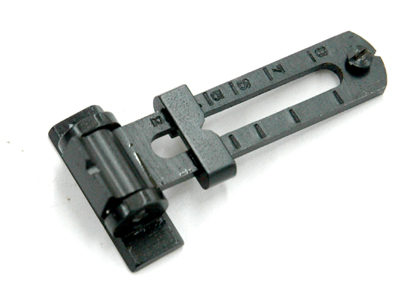

That's a nice looking rifle! I love me some oct-round or oct-hexadecagon barrels! Is it tapered or just appear that way because of the transition? I'd prefer if companies that make non-forgery side locks would adopt less drop at the heel, even this stock, it's going to want to rotate up on ya a bit, but I never realized how nice the fore end looks on the old Renegades with that simple sculpting to the nose, goes with the barrel. maybe you get time later, you could make a nose cap to match the trigger guard, but cut it away it to still show off the wood a bit something like on this Austrian Jaegerstutzen, it even has a very similar trigger guard and barrel profile, just the transition happens later (it's for a bayonet in that case lol, photo from capandball.com)! The nose cap almost could be continued down to be a sort of "entry pipe" into the stock for the rod. They had tang mounted aperture sights, if we made that TC sight look a little more "antiquey" you could almost pass it off as a facsimile of a rifle that was privately owned by an Austrian-allied soldier lol. And to think, you pieced that thing together from other guns, that's cool!

Last edited:

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

That's a nice looking rifle! I love me some oct-round or oct-hexadecagon barrels! Is it tapered or just appear that way because of the transition? I'd prefer if companies that make non-forgery side locks would adopt less drop at the heel, even this stock, it's going to want to rotate up on ya a bit, but I never realized how nice the fore end looks on the old Renegades with that simple sculpting to the nose, goes with the barrel. maybe you get time later, you could make a nose cap to match the trigger guard, but cut it away it to still show off the wood a bit something like on this Austrian Jaegerstutzen, it even has a very similar trigger guard and barrel profile, just the transition happens later (it's for a bayonet in that case lol, photo from capandball.com)! The nose cap almost could be continued down to be a sort of "entry pipe" into the stock for the rod. They had tang mounted aperture sights, if we made that TC sight look a little more "antiquey" you could almost pass it off as a facsimile of a rifle that was privately owned by an Austrian-allied soldier lol. And to think, you pieced that thing together from other guns, that's cool!

View attachment 88389

What I wish I could do along those lines would be to make my New Englander look sorta like an Enfield Musketoon. But that would require a complete custom stock among other things and skill that's above my pay-grade.

Wildrangeringreen

40 Cal

What I wish I could do along those lines would be to make my New Englander look sorta like an Enfield Musketoon. But that would require a complete custom stock among other things and skill that's above my pay-grade.

One could just face the nose of the stock, and then join with glue an extension on the front (a simple lap-joint will do, as long as you make it about an inch). I'd then cover the joint with the rear barrel band. The stock work could be roughed out with a saw, carving knives/chisels, and a file.

Barrel bands can be made with 1/8" steel plate from Menard's. if you have a MAPP (propane is cheaper, just takes longer) Torch and a hacksaw, you can make the barrel bands. You'll need to heat the steel up to bend it close to the shape, then cold bend it the last bit to fit close, drill and tap the bolt-hole, then heat it up bright red and quench, then draw temper back with an oven turned all the way up for 20-30 min or by placing in a pot of barely molten lead. the band should be slightly springy, but not brittle. Both bands are held on with tension on the bands by a bolt running through them, rather than the French-style spring clips, so perfect fit isn't required.

An Enfield's rear sight was held on with solder, but you could easily reuse the bolt holes that held the original NE rear sight on that are in the barrel (I think that sight was held on with small machine screws?), just drill holes in the sight base and contour it to match the barrel with a round file and sandpaper taped to the barrel. If you don't want to use blind screws, you could solder it on, I would just use 95tin/5antimony solder for the sight (that stuff is pretty darn strong, I've even used it for barrel tenons, holds well with a good joint). That solder usually melts around 510'F, so if you don't have to get the barrel too excessivly hot. You can get away with lower temp 60/40 tin-lead (360'F) or 97/3 tin-copper solder (440'F)for sights though, as they generally don't have to hold back much recoil force (they just gotta hang on for dear life lol). Make sure to strip the bluing and oil at the joint on the base and the barrel, and clean up any pitting. Make a broad trace permanent marker around the outline of the base on to the barrel to act as a resist.

If you can put your barrel and sight base in the oven, it's real easy to get the barrel close to (but below) the melting temp of your solder, so it doesn't take as long to make the solder flow. Remove your sight from the oven, flux the joint, and proceed to heat the top of the base (not the joint side) until the solder starts to flow, you will then apply a healthy coat of solder to the joint side of the base (this is called "tinning"). You will allow that solder to solidify, you may then place it back into the oven to keep warm while to perform the same process on the barrel. Then remove the warm sight base from the oven, wire it to the barrel (soft steel wire, wrap it around tight and twist it down to make it tighter (required to hold everything in place while the solder it molten). Then heat the barrel and sight base together, moving the flame around until the solder melts together (you'll see it flow together). Stop heating, and allow to cool. Carefully remove excess solder with a box cutter and then with files. use Alcohol to remove the marker resist. Blue any exposed steel (if any).

If you're not dead-set on a true Enfield sight, you could just cheat and cut a dovetail with a hacksaw + safe-triangle file and install a 1866 win or 1873 win tangent sight. You'd have most of the functionality, without the complexity lol.

If you make it a winter project (heated workspace) or something, or are just willing to have it on the bench for a while, you can work on it "one piece at a time", and it'll get done (even if it takes ya to retirement lol) ( seriously, it saves ya from getting frustrated, if you can put it down and walk away between each process if it's bothering you) (pics are from DGW)

Last edited:

- Joined

- Mar 13, 2020

- Messages

- 7,495

- Reaction score

- 21,016

- Location

- On the Border in Idaho looking at BC

well Bubba, now we will see if i can operate more than a straight turnscrew. i dropped my flintlock today and snapped the wrist (again). running out of solid wood to fix so i am going to gouge out a new stock for it. maybe if i sharpen my turnscrews enough i won't have to find my chisels and gouges.

Turned out fine, to my way of thinking. Old timers did the same thing back in the day. Lots of "originals" I've seen and several I've owned were made up of parts from varying sources. Long before "kits" were popular, if a shooter wanted a particular setup, assembling a set of parts was part of the fun. Still is.

bubba.50

Barefoot Hillbilly

- Joined

- Aug 21, 2010

- Messages

- 3,837

- Reaction score

- 3,348

well Bubba, now we will see if i can operate more than a straight turnscrew. i dropped my flintlock today and snapped the wrist (again). running out of solid wood to fix so i am going to gouge out a new stock for it. maybe if i sharpen my turnscrews enough i won't have to find my chisels and gouges.

Sorry for your misfortune. But l’m sure you’ll persevere and it will turn out fine. Post a pik or two when ya ‘git-r-did’.

- Joined

- Mar 13, 2020

- Messages

- 7,495

- Reaction score

- 21,016

- Location

- On the Border in Idaho looking at BC

got it glued and clamped. tomorrow i am going to dig out some raw hide, and go full mountain man on that english/italian gun!

going to wet wrap it and let it shrink. then i will start looking for a new piece of wood. like i needed another project

going to wet wrap it and let it shrink. then i will start looking for a new piece of wood. like i needed another project

Similar threads

- Replies

- 12

- Views

- 2K

- Replies

- 32

- Views

- 7K

- Replies

- 110

- Views

- 10K