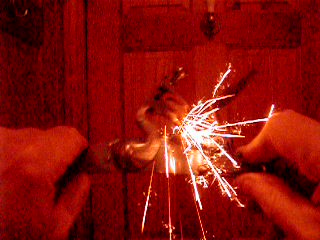

I have made and own exactly one flint lock gun-

https://www.muzzleloadingforum.com/threads/hand-cannon-project.121442/page-2#post-1740020And honestly have had very little hands on experience with flintlocks in general.

Anyway, the frizzen on the hand cannon is getting pretty scraped up from use, and I don't know how normal that is.

Is there a standard for hardness? I have the equipment to harden and anneal the steel with pretty fair precision, as well as the ability to test and confirm.

thanks in advance- T

https://www.muzzleloadingforum.com/threads/hand-cannon-project.121442/page-2#post-1740020And honestly have had very little hands on experience with flintlocks in general.

Anyway, the frizzen on the hand cannon is getting pretty scraped up from use, and I don't know how normal that is.

Is there a standard for hardness? I have the equipment to harden and anneal the steel with pretty fair precision, as well as the ability to test and confirm.

thanks in advance- T