damron said:

roundball said:

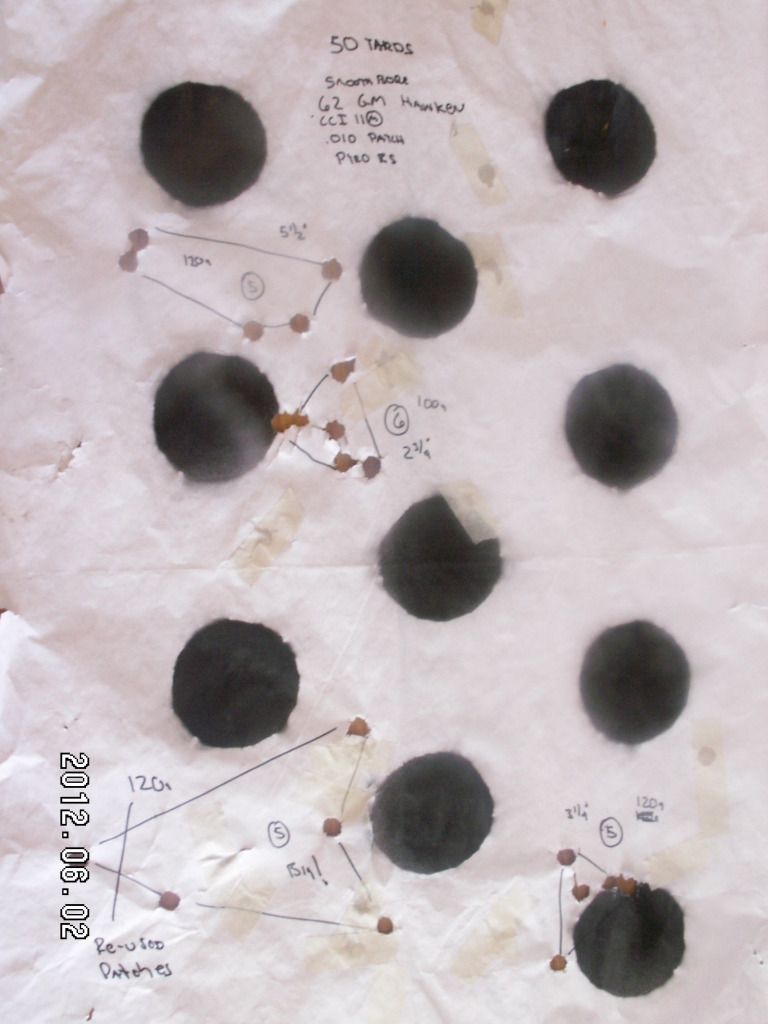

My .62cal is a smooth rifle with a Rice barrel having a 1&1/8" breech...and doing load development for woods hunting on the east coast the most I ever tested was 120grns Goex 2F, settled on a moderate 110grn charge for whitetails.

I am just working up loads for my .62 cal (.615) GM barrel.All i have is a .575 ball mold right now.With 90g of FF Goex and denim patch i am getting about 6" at 50 yards for 5 shots.

How much better can i expect?

Should i get a .590 to .600 ball mold and go with thinner patches?

George

My personal opinion is that .62cal smoothbores (smooth rifles with rear sights) should shoot about like a rifle at 50yds.

There are so many variables, particularly with smoothbores, that I couldn't tell you what "would work" in your particular barrel.

I will say that I've always leaned towards thicker patches...for example, my .62cal is a true .620" and a .600"/.022" PRB combination does best for me in that barrel.

(2.5" at 50yds sitting down shooting from a hunting position like leaning against a tree.)

Another thing helps my accuracy is that I drive the PRBs under a pretty strong head of steam so they don't slow down much and start wandering by the time they get to 50yds.

Doing load development for this deer load, as I was stepping up through 10grn increments of Goex 2F, when I hit 110grns the muzzleblast started sounding like a "crack" and the group size shrunk in half. 120grns didn't make it any better, and trying 100 again it started to open back up some, so I settled on 110grns.

Based on the above, all I could do is suggest how I'd approach it which would be to try something similar in your .615" bore:

.020" Oxyoke patch and .595" ball. (Oxyoke .020" patches actually seem to measure .022")

(You can order the patches and a trial bag of 25 .595"s from Track of the Wolf to experiment with).

Test 3 shot groups of 80/90/100/110/120grns Goex 2F (or equivalent) at 25yds, then take the best one and move to 50yd...step up the powder charge as you need to.