I have a Peter Berry flintlock from about 2003, maple stock, Cain lock, double-set trigger. I'm having fits with my hammer not staying cocked. I relieved the action at first. I live in a humid state, so assumed swelling might have been pressing on the lock. Then I relieved the trigger area where it was pressing on the trigger group. I cleaned the lock and trigger up somewhat. It will stay cocked now if I pull the set trigger before cocking. Sometimes the hammer will fall by pulling the trigger, and sometimes I have to pull the set trigger again. I've adjusted the trigger set screw, but no miracles there. Thoughts? Thank you.

-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hammer won't stay cocked

- Thread starter fc

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

timothy prouty

40 Cal.

- Joined

- Apr 2, 2016

- Messages

- 267

- Reaction score

- 0

It might be the Tang screw be to rite or you have a set trigger that you got to set the trigger before you can **** the hammer

timothy prouty

40 Cal.

- Joined

- Apr 2, 2016

- Messages

- 267

- Reaction score

- 0

YOU can try to file the arm on the sear. DO it works when it out of the stock?

- Joined

- Mar 4, 2013

- Messages

- 307

- Reaction score

- 210

'morning,

You mentioned it has DST. I have a Sharps that occasionally has a similar issue. Have you checked the trigger adjustment screws?

I'm drawing a blank on the names at the moment, but my Sharps has two. One between the triggers, that affects the let off once the set trigger is pulled. There is a second (that I didn't know about until I started experiencing issues) behind the rear trigger. It actually affects the sear in some way, and if it's too loose, you get the same symptoms you are experiencing.

Playing around with it, I found that too tight and it wouldn't hold full **** at all. Too loose and it only holds with the set trigger set. Once I found where everything worked, I backed it out (counting revolutions) and used some Loc-Tite, making sure that things still worked right before it set up.

Best of luck!

Calum

You mentioned it has DST. I have a Sharps that occasionally has a similar issue. Have you checked the trigger adjustment screws?

I'm drawing a blank on the names at the moment, but my Sharps has two. One between the triggers, that affects the let off once the set trigger is pulled. There is a second (that I didn't know about until I started experiencing issues) behind the rear trigger. It actually affects the sear in some way, and if it's too loose, you get the same symptoms you are experiencing.

Playing around with it, I found that too tight and it wouldn't hold full **** at all. Too loose and it only holds with the set trigger set. Once I found where everything worked, I backed it out (counting revolutions) and used some Loc-Tite, making sure that things still worked right before it set up.

Best of luck!

Calum

fc said:I have a Peter Berry flintlock from about 2003, maple stock, Cain lock, double-set trigger. I'm having fits with my hammer not staying cocked. I relieved the action at first. I live in a humid state, so assumed swelling might have been pressing on the lock. Then I relieved the trigger area where it was pressing on the trigger group. I cleaned the lock and trigger up somewhat. It will stay cocked now if I pull the set trigger before cocking. Sometimes the hammer will fall by pulling the trigger, and sometimes I have to pull the set trigger again. I've adjusted the trigger set screw, but no miracles there. Thoughts? Thank you.

I assume that the triggers and lock are working just fine when the lock is removed from the stock. You have good parts that probably should be nearly flawless.

I think that flinter36 is correct. The tang screw, if it threaded into the trigger plate, is too tight and has compressed the wood in the trigger plate mortise raising the trigger bar. The best solution is to put some sort of shim in the trigger mortise. This can be a slim sliver of wood or a few sheets of paper.

Just tighten the tang screw to snug. There is no need to really tighten any of the screws really brute force tight. This is true for the the tang screw and the lock bolts. over tightening can lead to the problems you are mentioning.

- Joined

- May 6, 2014

- Messages

- 17,431

- Reaction score

- 16,433

Calum said:There is a second (that I didn't know about until I started experiencing issues) behind the rear trigger. It actually affects the sear in some way, and if it's too loose, you get the same symptoms you are experiencing.

Calum

EXACTLY!!

In the following link, that rear screw is called the Mainspring Screw of the set triggers, but I don't know if that is what it is normally called. http://www.lr-rpl.com/index.php?op...-parts-diagram&catid=41:information&Itemid=68

I had a shooter bring me a Pedersoli single shot target Pistol that was doing the exact same thing the OP is describing. I always ask if they did anything to the lock or set triggers and he said he had only adjusted the set screw that comes out from under the trigger plate. Re-adjusting that screw did nothing to fix the problem.

I took the lock out and ensured the lock screws were snug, but not too tight where they would have bound up the tumbler or sear. There was nothing wrong with the fly nor the sear surface of the tumbler or anything else wrong with the lock.

The Set triggers worked perfectly outside the pistol, but would not work correctly in the pistol.

I tried using shims to get the triggers lower and that did not work. I tried loosening the tang screw and properly retightening and that did not work.

There was no damage to any of the parts.

I was just about at my wits end after trying everything else, when it occurred to me that either the current owner of the pistol or the previous owner MAY have messed with the adjustment of the mainspring screw, in hopes of getting a lighter trigger pull.

I was surprised how much force it took to tighten the mainspring screw back down tight and wondered if I was making things worse. However, all of a sudden the set trigger and lock worked perfectly when assembled into the pistol without shims or anything else.

When I returned the pistol to the owner the next day and discussed what was wrong, he finally remembered he had loosened the mainspring screw.

Gus

Last edited by a moderator:

Your trigger assembly has moved too far into the stock so the rear trigger blade is touching the locks sear arm.

These trigger blades are soft steel so it is easy to file a little off of the top of the blade.

(Make sure your filing on the rear triggers blade. The front trigger also has one and you don't need to mess with it.)

Another option was mentioned above. Put a shim or two under the trigger plate where it seats against the stock wood.

This shim will lower the trigger plate and set triggers blades away from the lock sear arm.

These trigger blades are soft steel so it is easy to file a little off of the top of the blade.

(Make sure your filing on the rear triggers blade. The front trigger also has one and you don't need to mess with it.)

Another option was mentioned above. Put a shim or two under the trigger plate where it seats against the stock wood.

This shim will lower the trigger plate and set triggers blades away from the lock sear arm.

I'll try to follow the advice you all gave, and I thank you for it. Some of it is hard to visualize, but I'll re-read them. I have the set screw backed off, because the more it is screwed in, the worse it gets. The hammer stays back if out of the wood. When it was first acting up, if I started tightening the lock screws the hammer would fall. That baffled me. The shim idea may help. I'd put on some pictures, but the image icon wants a URL. The pictures are on my computer. It's a James Klein gun. I wonder if he's around anymore?

timothy prouty

40 Cal.

- Joined

- Apr 2, 2016

- Messages

- 267

- Reaction score

- 0

Get a candle can try to darken the edge of the Sears arm so when tighten it it will leave a mark in the wood cuz it sound like the seers arm is too long

Listen to Zonnie: before you start filing metal, remove the set triggers from the stock and put some paper/cardboard shims in the bottom of the inlet and put the set triggers back in. In many cases this solves the problem and is quick and easy. If that doesn't work-then consider the other ideas.

To get the pictures from your computer to this site, you have to upload them to a photo editing site first. I use Tinypic.com it's free and easy to use.fc said:I'll try to follow the advice you all gave, and I thank you for it. Some of it is hard to visualize, but I'll re-read them. I have the set screw backed off, because the more it is screwed in, the worse it gets. The hammer stays back if out of the wood. When it was first acting up, if I started tightening the lock screws the hammer would fall. That baffled me. The shim idea may help. I'd put on some pictures, but the image icon wants a URL. The pictures are on my computer. It's a James Klein gun. I wonder if he's around anymore?

I had the same problem with my Hatfield with the hammer falling when the lock was tightened up. I found two things causing that. One of the lock screws was bent and would **** the lock down causing no clearance between the sear and trigger and the trigger mounting screws were over tightened further reducing the clearance.

Last edited by a moderator:

Tom Compton

54 Cal.

- Joined

- Oct 21, 2008

- Messages

- 1,893

- Reaction score

- 193

Hammer trips as the lock screws are tightened? Hmmm.

I've seen double set triggers w 3 screws. One holds the trigger main spring down against the rear trigger providing the force. The other is between the two triggers to regulate sear engagement. The third is behind the rear trigger and limits the travel of the spring and therefore how high the bar is placed when the triggers are not set. Maybe you have this arrangement and if so back that screw our a half turn or so.

TC

I've seen double set triggers w 3 screws. One holds the trigger main spring down against the rear trigger providing the force. The other is between the two triggers to regulate sear engagement. The third is behind the rear trigger and limits the travel of the spring and therefore how high the bar is placed when the triggers are not set. Maybe you have this arrangement and if so back that screw our a half turn or so.

TC

fc

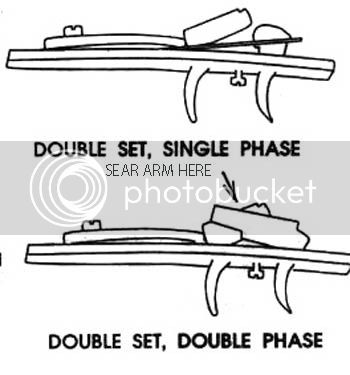

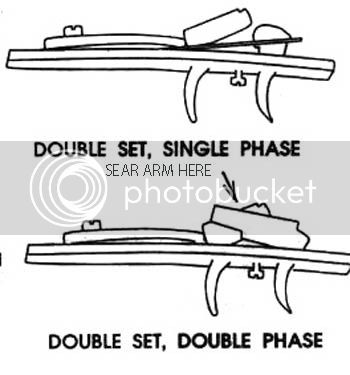

Maybe this picture will help you visualize things a little?

For the moment, ignore the top drawing and study the bottom one.

The lock has a arm that sticks out away from the lockplate that is a a part of its sear. The sear holds and releases the hammer by engaging notches in the lock tumbler.

When things are installed into the stock, the locks sear arm is located where the arrow is pointing.

Notice the angular line that represents the front trigger blade in front of the (rear) set triggers trigger blade?

This drawing is showing the front trigger blade like it would be if a finger was lightly pulling the front trigger. (Normally, the front trigger would be slightly forward and its blade would be lower.)

That rear trigger blade is shown in the "uncocked" or "unset" position with its spring holding the blade up. That's the way it normally is and it usually is very close to the lock sear arm.

If the set trigger assembly is installed to deeply in the stock, that rear triggers blade will push the sear arm up far enough that the lock sear can't engage the full **** notch in the tumbler.

If that happens, the lock cannot be set to full ****.

If a spacer or shim is placed between the trigger plate and the wood in the bottom of the slot (mortise) in the stock, the whole trigger assembly will move down.

This moves the top of the rear triggers blade down, away from the sear arm.

With nothing now stopping the sear arm from moving down, it can now engage the full **** notch in the tumbler and the lock will remain cocked.

Did this make sense?

If it did, you can understand why filing some material off of the top of that rear triggers blade will achieve the same thing.

The blade will no longer be pressing upward on the sear arm.

About this "tightening the lock screws released the hammer" idea:

More than a few locks fit somewhat loosely in the lock mortise. When they are slipping into place, they often will **** or tilt slightly and the locks sear will be higher than it normally is.

As the lock screws tighten down, the lock hits the bottom of the mortise and begins to "square up" to a normal position.

As it "squares" or straightens up, the sear arm moves slightly downward.

If one of the trigger blades is in the way, further tightening of the lock screws can cause it to move so far that it suddenly releases the tumbler and hammer so the hammer falls.

Maybe this picture will help you visualize things a little?

For the moment, ignore the top drawing and study the bottom one.

The lock has a arm that sticks out away from the lockplate that is a a part of its sear. The sear holds and releases the hammer by engaging notches in the lock tumbler.

When things are installed into the stock, the locks sear arm is located where the arrow is pointing.

Notice the angular line that represents the front trigger blade in front of the (rear) set triggers trigger blade?

This drawing is showing the front trigger blade like it would be if a finger was lightly pulling the front trigger. (Normally, the front trigger would be slightly forward and its blade would be lower.)

That rear trigger blade is shown in the "uncocked" or "unset" position with its spring holding the blade up. That's the way it normally is and it usually is very close to the lock sear arm.

If the set trigger assembly is installed to deeply in the stock, that rear triggers blade will push the sear arm up far enough that the lock sear can't engage the full **** notch in the tumbler.

If that happens, the lock cannot be set to full ****.

If a spacer or shim is placed between the trigger plate and the wood in the bottom of the slot (mortise) in the stock, the whole trigger assembly will move down.

This moves the top of the rear triggers blade down, away from the sear arm.

With nothing now stopping the sear arm from moving down, it can now engage the full **** notch in the tumbler and the lock will remain cocked.

Did this make sense?

If it did, you can understand why filing some material off of the top of that rear triggers blade will achieve the same thing.

The blade will no longer be pressing upward on the sear arm.

About this "tightening the lock screws released the hammer" idea:

More than a few locks fit somewhat loosely in the lock mortise. When they are slipping into place, they often will **** or tilt slightly and the locks sear will be higher than it normally is.

As the lock screws tighten down, the lock hits the bottom of the mortise and begins to "square up" to a normal position.

As it "squares" or straightens up, the sear arm moves slightly downward.

If one of the trigger blades is in the way, further tightening of the lock screws can cause it to move so far that it suddenly releases the tumbler and hammer so the hammer falls.

I had a similar problem. I loosed up on the lock screw for a temporary fix, removed the lock and did a little (very little) inletting for a permanent fix. I'd try that before filing on steel, but I'm no gunsmith.

- Joined

- May 6, 2014

- Messages

- 17,431

- Reaction score

- 16,433

Gene,

So it is clear to the OP, what kind of inletting did you do?

I imagine it was to clear the wood from any place where the tail of the sear was hitting inside the stock and not allowing the sear face to go fully upwards and properly engage the half **** notch?

Gus

Edited to add: The reason I mention this is because what often is the problem is the tail of the sear is too close to the top of the set triggers, when the sear leg is not being held up too high by the wood. If one inlets the set triggers deeper, it compounds the problem and will make it worse.

So it is clear to the OP, what kind of inletting did you do?

I imagine it was to clear the wood from any place where the tail of the sear was hitting inside the stock and not allowing the sear face to go fully upwards and properly engage the half **** notch?

Gus

Edited to add: The reason I mention this is because what often is the problem is the tail of the sear is too close to the top of the set triggers, when the sear leg is not being held up too high by the wood. If one inlets the set triggers deeper, it compounds the problem and will make it worse.

I can't remember, but I think it was on the seating on the lock. I DO remember it was to relieve the pressure on the trigger mechanism. I don't think you can have too much inlet on the trigger fit.

- Joined

- May 6, 2014

- Messages

- 17,431

- Reaction score

- 16,433

Gene,

Thank you for your explanation. I imagine most of what you did was to take wood out of the deep hole for the sear leg. There have been times I have had to take wood off the top and bottom of the hole and to a lesser extent, sometimes shorten the length of the sear leg so it did not rub all the way down inside the depth of the hole.

Gus

Thank you for your explanation. I imagine most of what you did was to take wood out of the deep hole for the sear leg. There have been times I have had to take wood off the top and bottom of the hole and to a lesser extent, sometimes shorten the length of the sear leg so it did not rub all the way down inside the depth of the hole.

Gus

Similar threads

- Replies

- 31

- Views

- 2K