Hey Chironomidkraut,

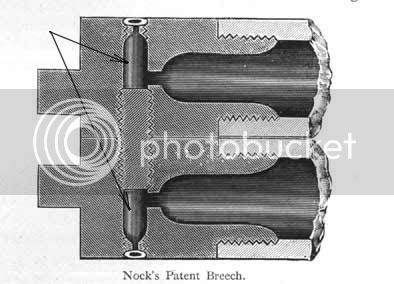

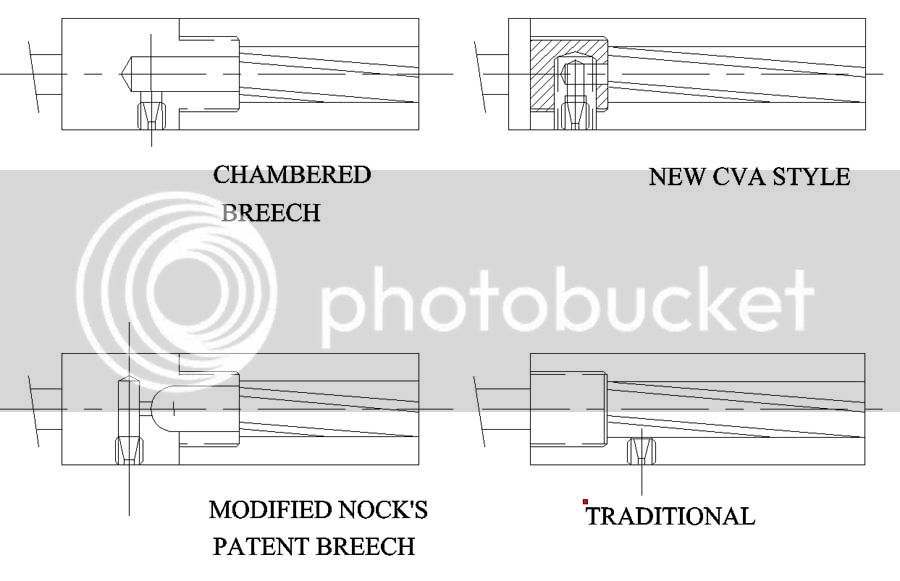

What gun is it that you are having the problem with? If it is a Traditions, Pedersoli, Lyman, or TC, then it has a patent breech. Basically that's a smaller pre-ignition chamber behind the main chamber of the barrel and located right in the center or the barrel. The touch hole shoots flame into the that smaller pre-ignition chamber and the powder from there ignites the main charge. I have one rifle with a patent breech (Traditions) and one without. I personally prefer the standard breech where they touch hole goes directly into the back of the the barrel from the side.

If you have a patent breech, you have to be really careful not to use a dripping-wet patch. If you do it will shove some of the fouling into that smaller hole at the breech of your rifle AND it will stay wet when you pour your powder down it. Needless to say, wet powder doesn't burn and that can cause a hang fire. And, of course, if you end up stuffing a bunch of crud in that pre-ignition chamber, the flash from your pan will never get to the powder. And, no amount of touch-hole picking will clear it.

Good news is that if you get one of those Co2 gadgets that blow Co2 in through the touch hole, it will clean the rascal right out with ease. It's made to push out a dry ball, but works just fine pushing out the wet powder too. If you have one of those gadgets and you used a patch that you suspect might have been too wet, use that little Co2 blower before you pour the powder down the barrel. It will blow that moisture and crud right out of the patent breech and you will be good to go.

I really don't care for patent breeches just because of the problems you are having. The standard breech works just fine and is not nearly so cantankerous!

Twisted_1in66 :thumbsup: