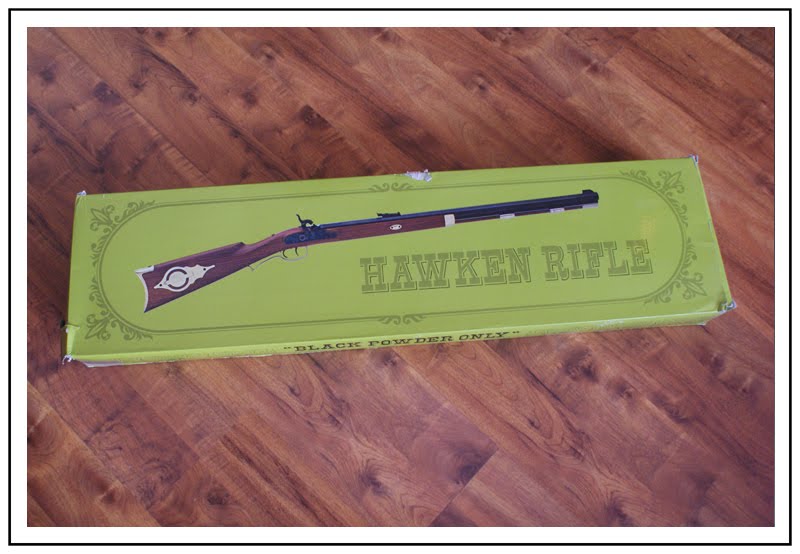

Some time ago I ordered a set:

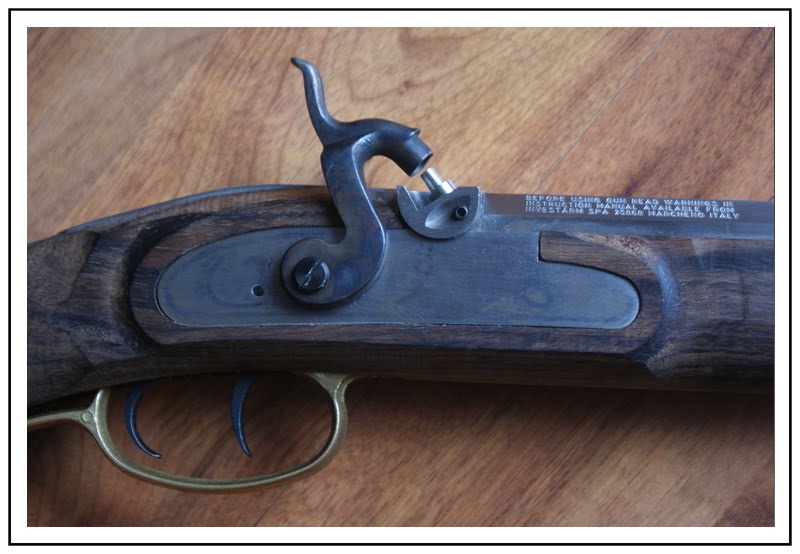

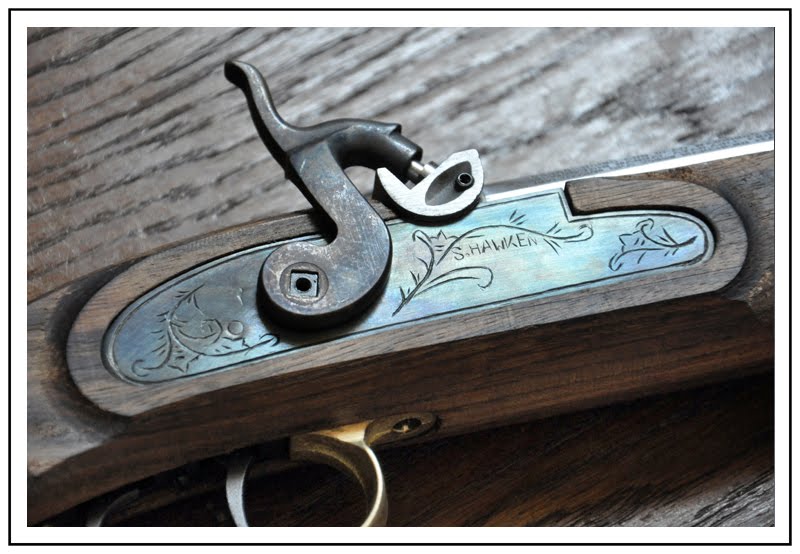

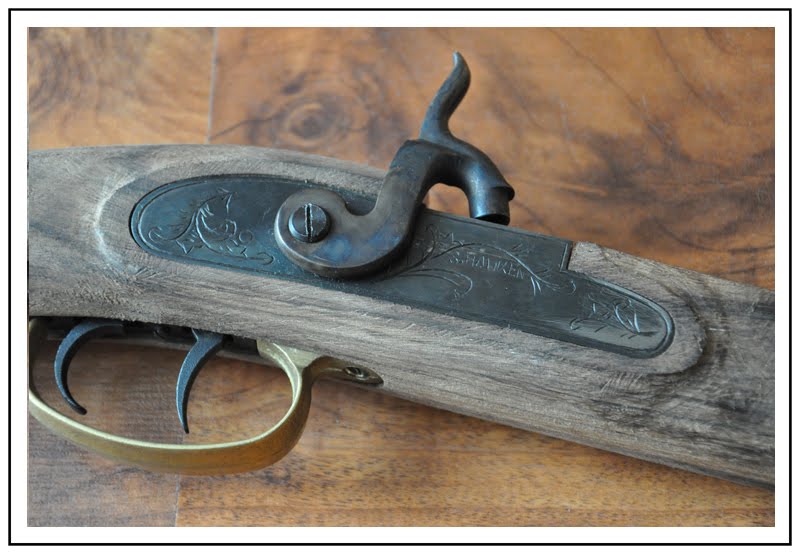

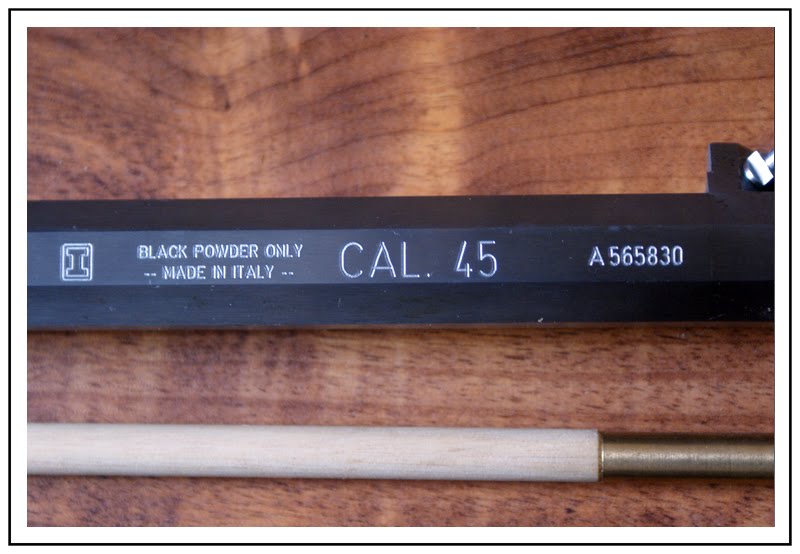

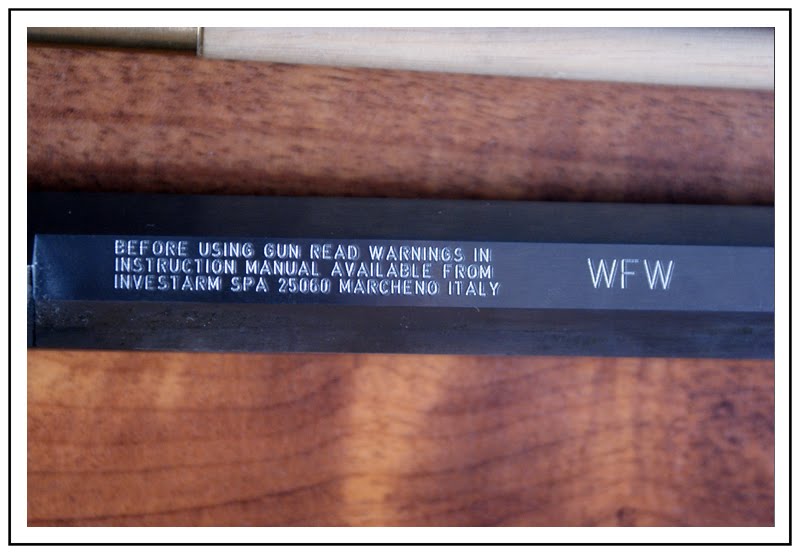

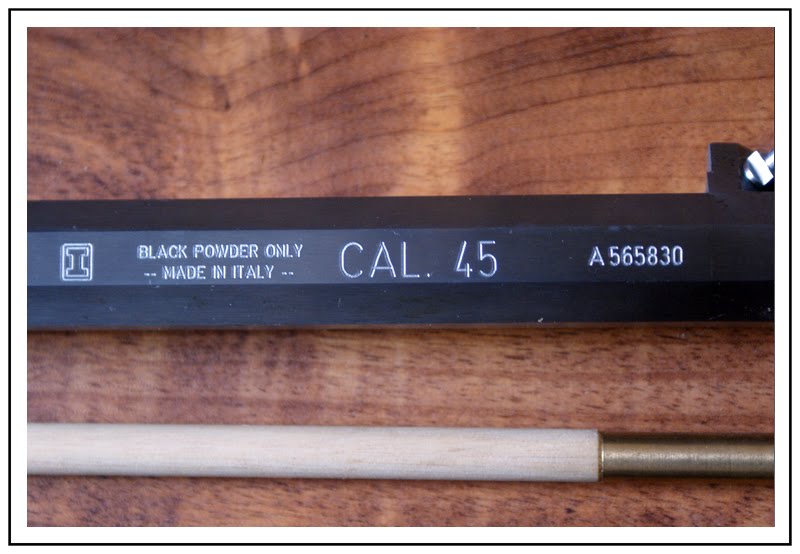

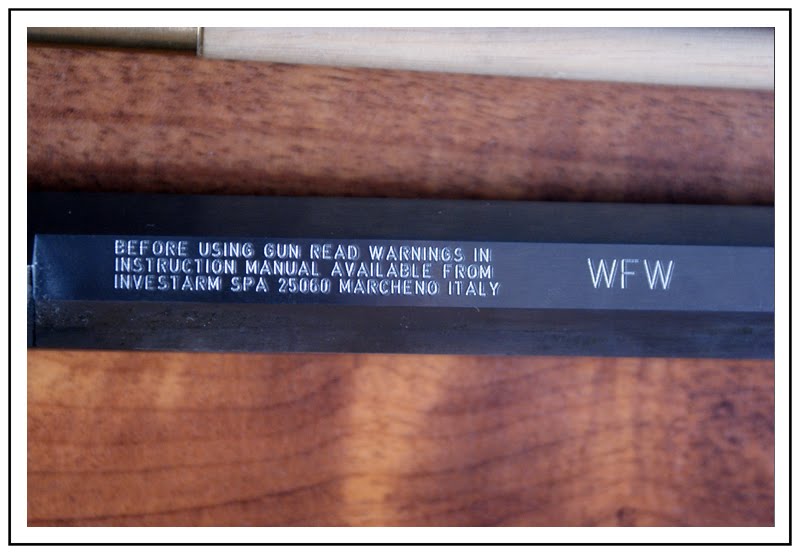

Investarm Hawken Kit

CAL 45, 1:48 pitch, total length 114cm, weight ~ 3.7 kg

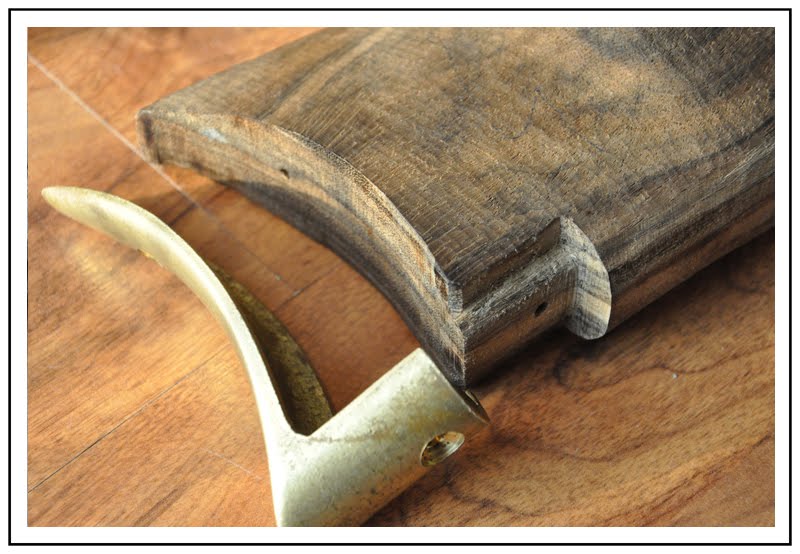

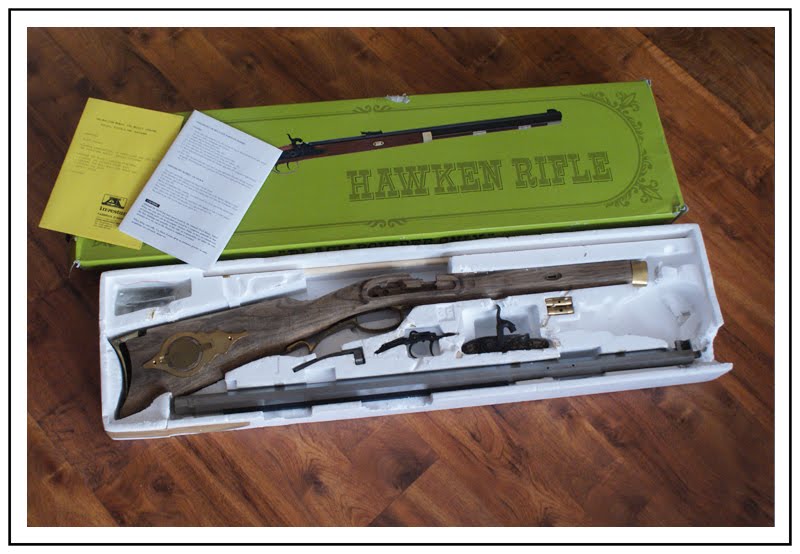

I was looking for something with a nice wood and managed to ... stock has a beautiful color and grain.

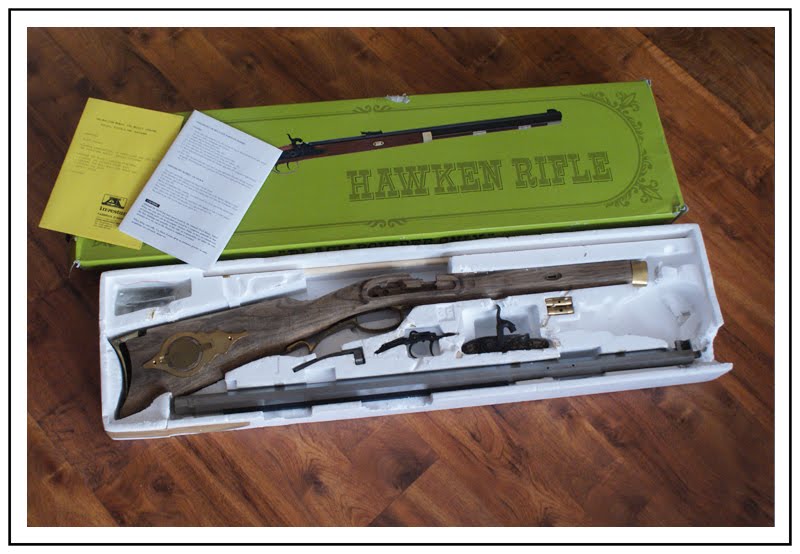

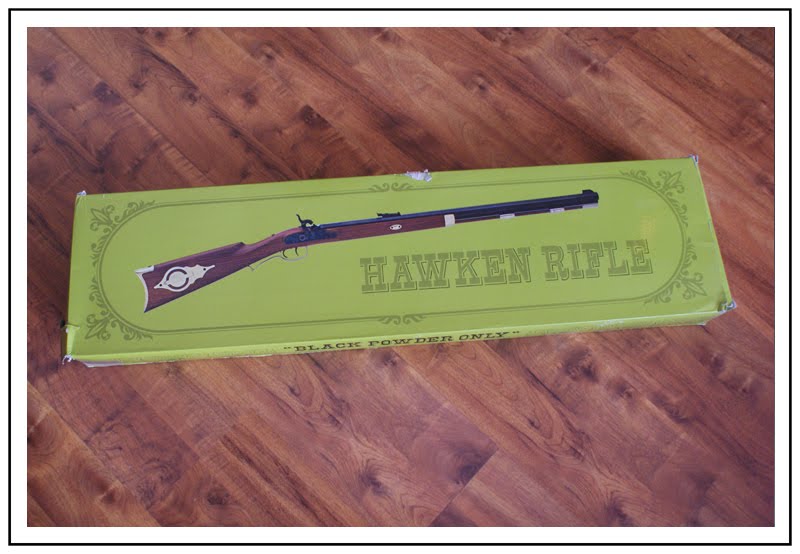

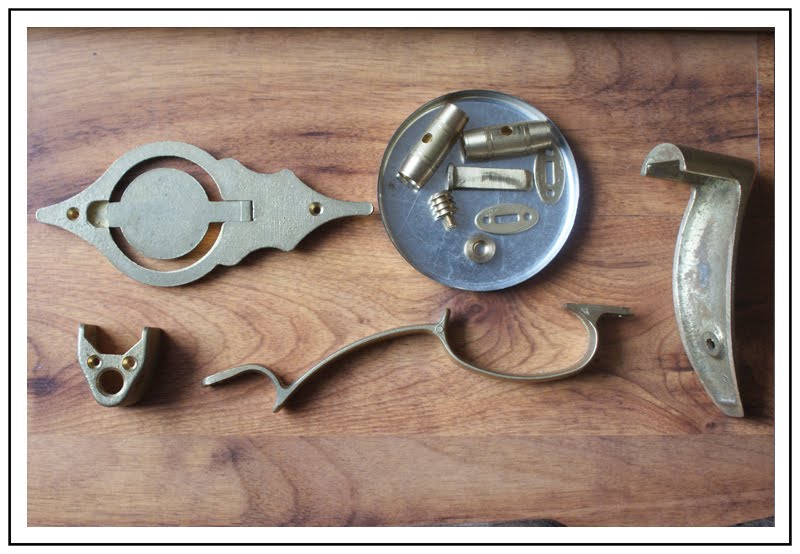

This was the set after unpacking the package

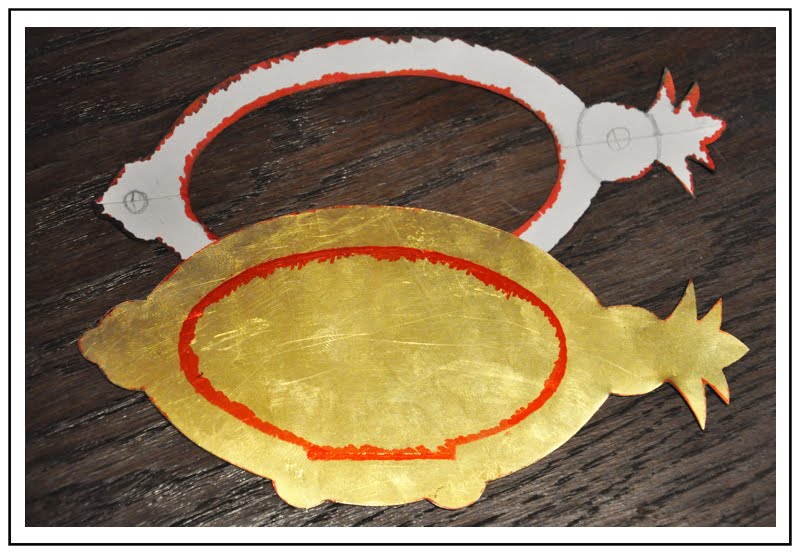

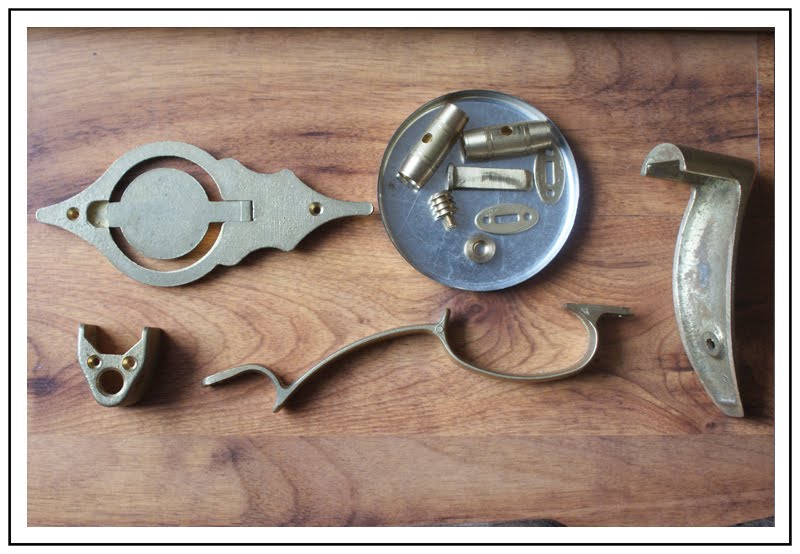

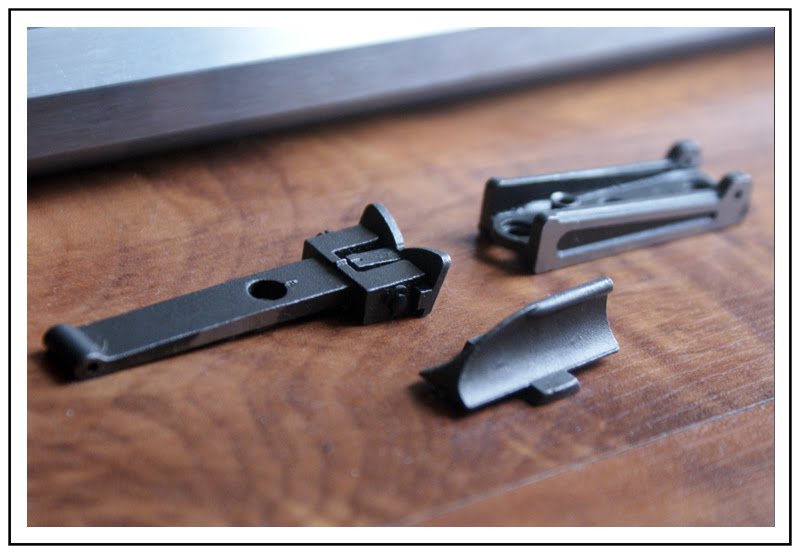

All items taken out of the box

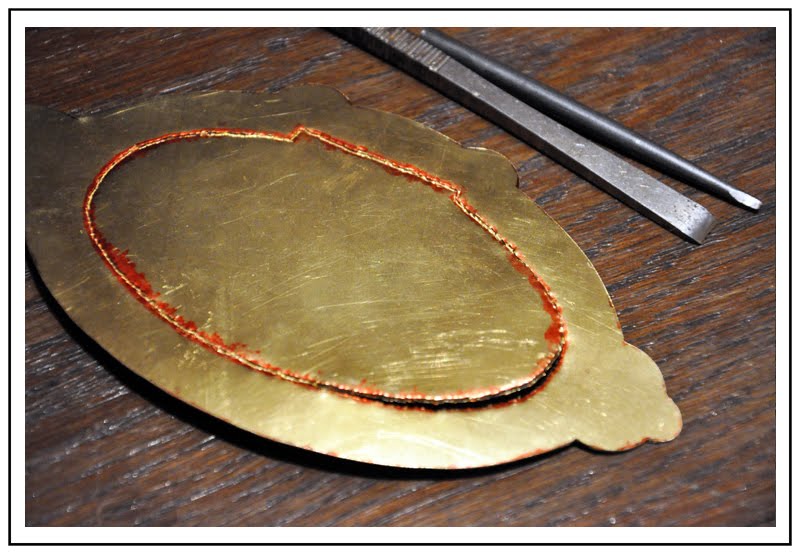

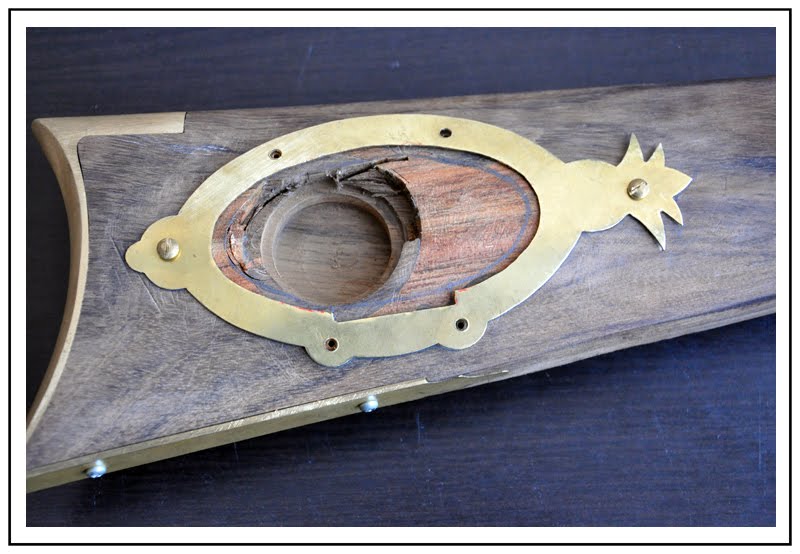

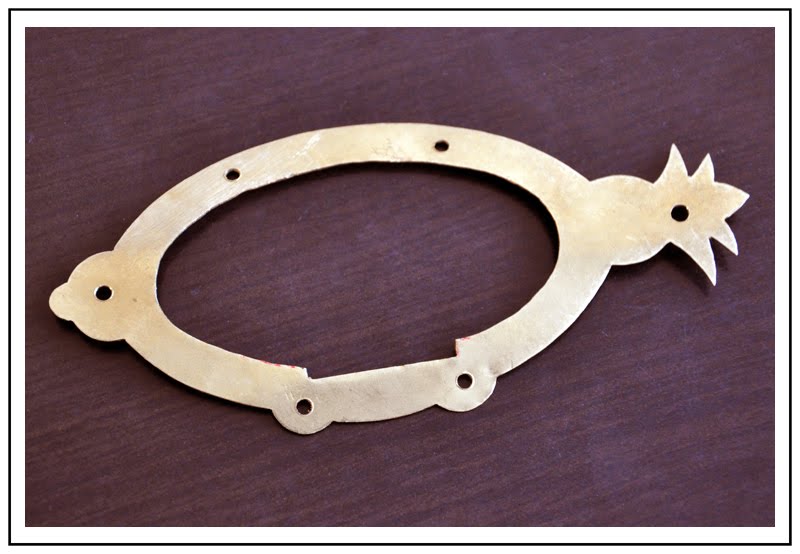

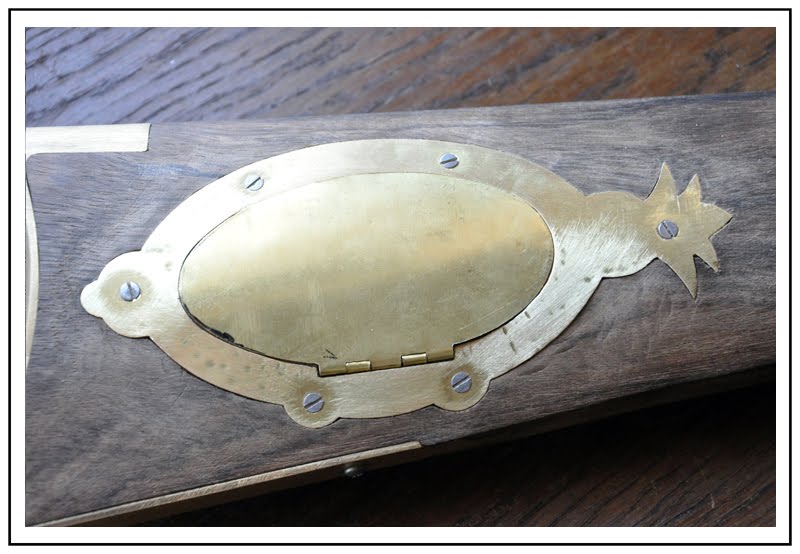

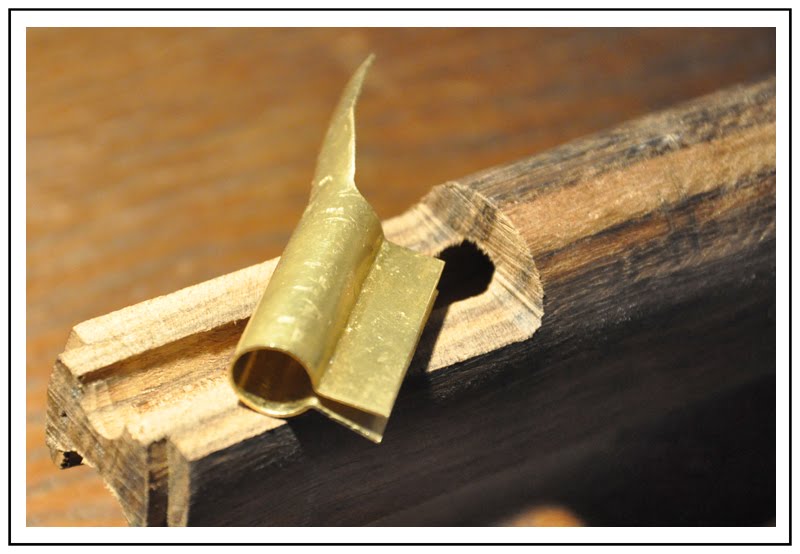

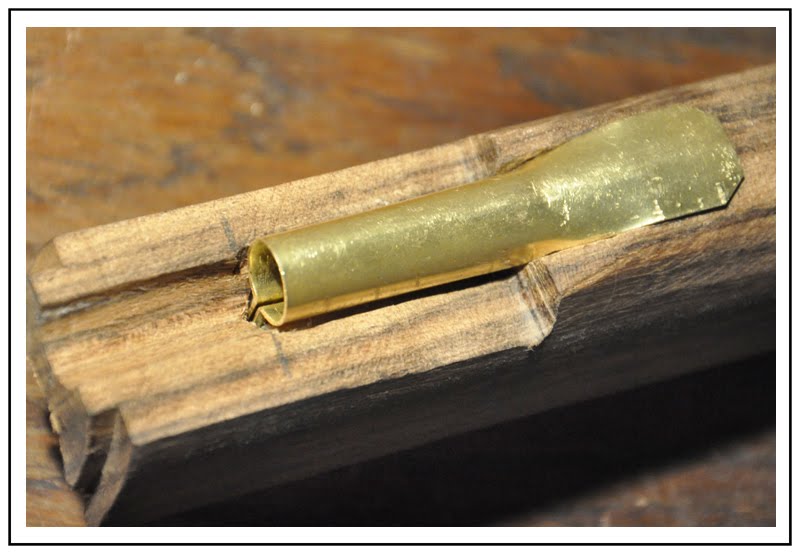

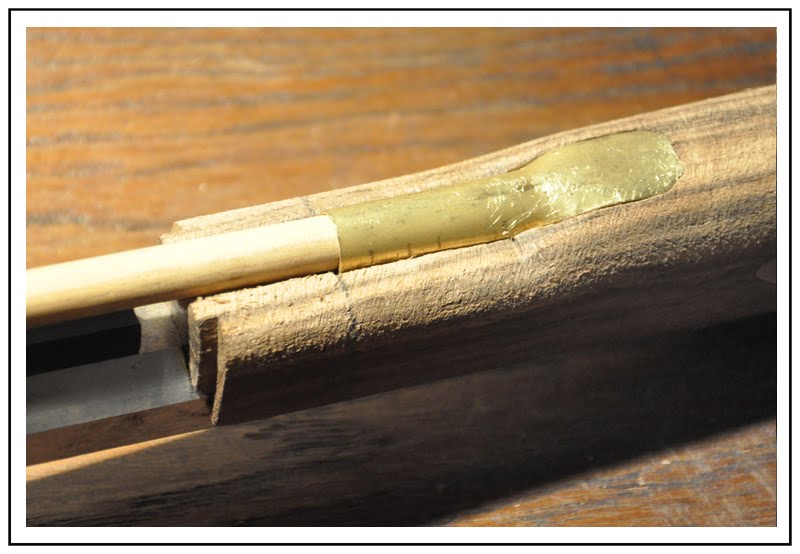

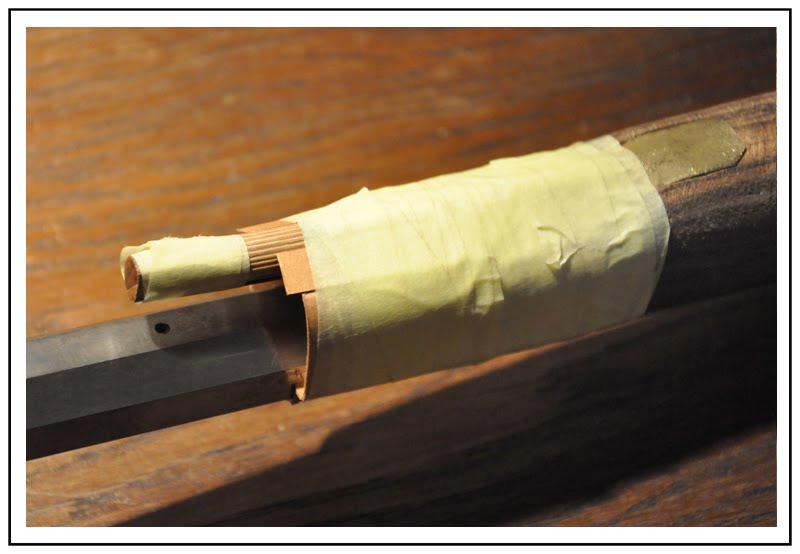

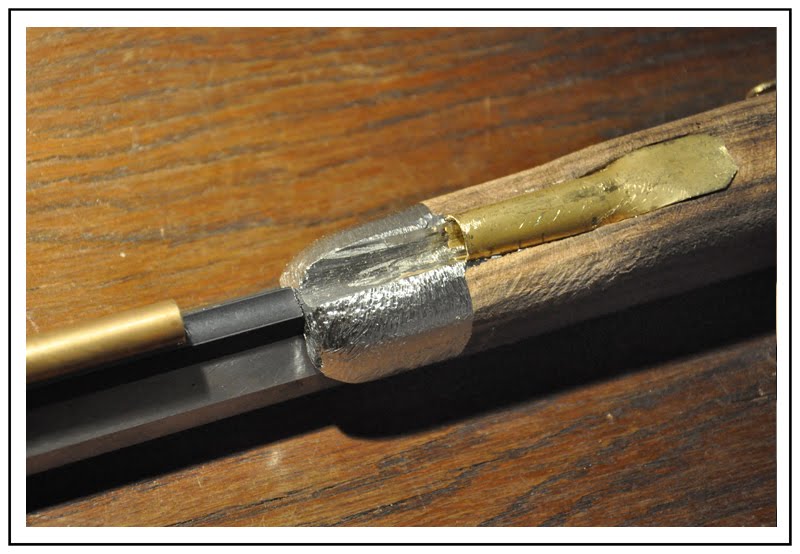

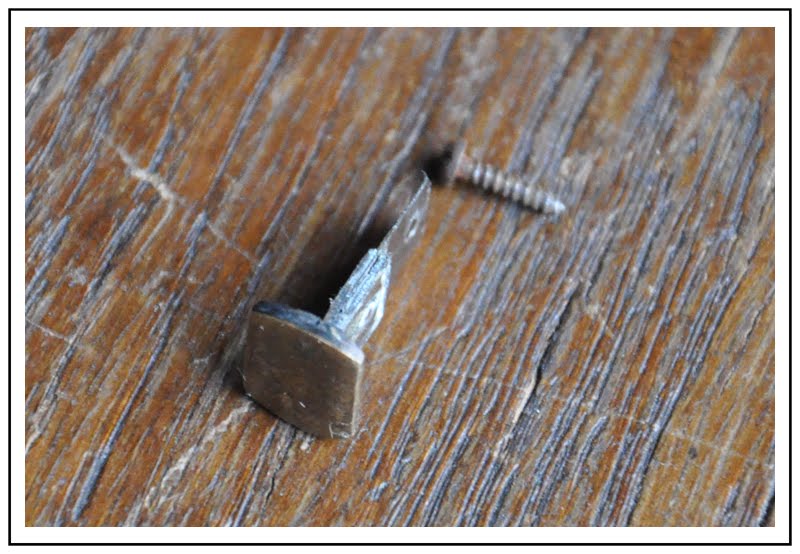

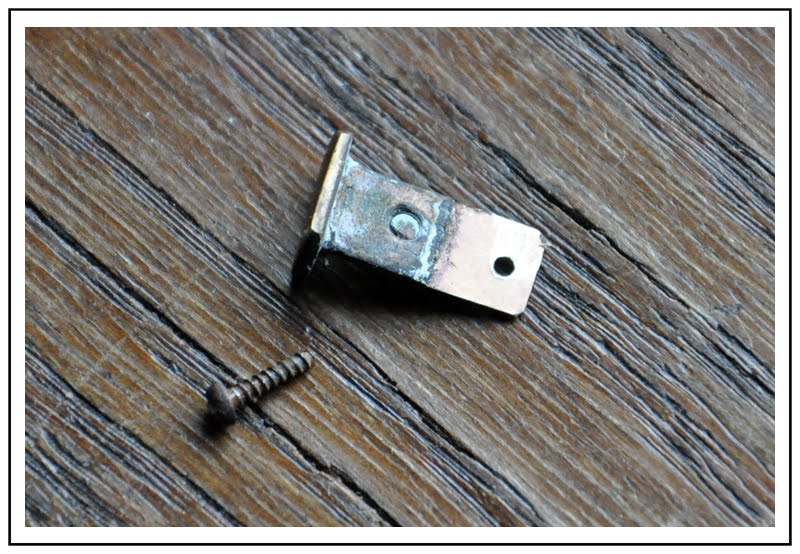

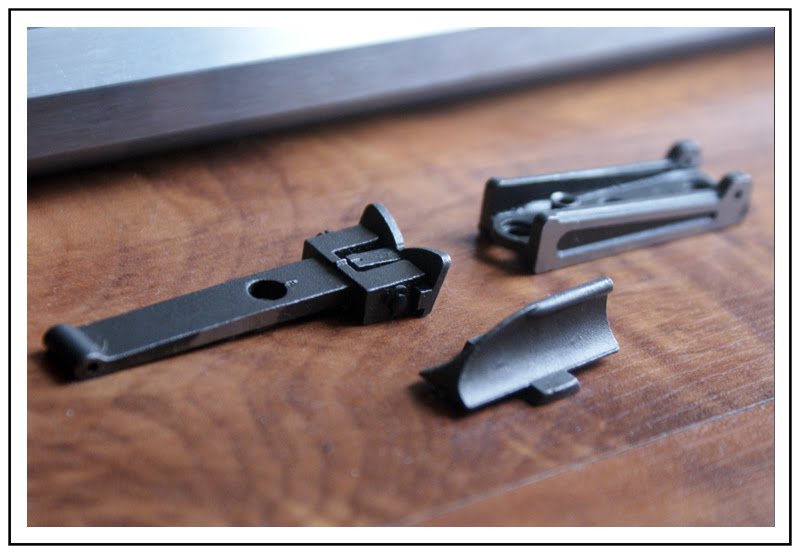

The first thing I did is fitting all the major components: hardware, barrel, lock and trigger. It turned out that the wood has a nice supply of treatment so I need not fear that I lack the material.

Investarm Hawken Kit

CAL 45, 1:48 pitch, total length 114cm, weight ~ 3.7 kg

I was looking for something with a nice wood and managed to ... stock has a beautiful color and grain.

This was the set after unpacking the package

All items taken out of the box

The first thing I did is fitting all the major components: hardware, barrel, lock and trigger. It turned out that the wood has a nice supply of treatment so I need not fear that I lack the material.