I have shot quite a few boxes of Hornady balls in my day and have not yet experienced what you did. For the last several years I have shot only balls that I have cast and have not bought any Hornady balls in probably 5 or 6 years.

Several years ago, I did a study on the consistency of Hornady balls and on their 000 buckshot that I was using in my .36 cal. rifle. I weighed and measured 2 separate batches of 000 buckshot. The first batch of 000 buckshot consisted of 365 balls. They were weighed on a Lyman electronic scale. The zero on the scale was checked before each ball was weighed. The calibration of the scale was checked before and after weighing all of the balls using calibrated weights of 50 grains and 100 grains. The first batch of balls ranged in weight from 64.2 grains to 65.7 grains with an average of 65.0 grains and a std. dev. of 0.2 grains. Next, I measured the diameter of each of the 365 balls. I used a 1 inch Starrett micrometer to measure the balls. The diameter of the balls ranged from .349 inches to .355 inches with an average of .351 and a std. dev. of .003 inches.

The second batch of Hornady 000 buckshot consisted of only 111 balls and only the weight was studied. this batch ranged from 63.7 grains to 65.1 grains with an average weight of 64.3 grains and a std. dev. of 0.3 grains.

Next, I studied three boxes of Hornady .395 balls. Two were full boxes and one had been opened and had only 85 balls left in it. The first box of 100 balls ranged in weight from 95.0 grains to 96.0 grains. The average was 95.4 grains with a std. dev. of 0.3 grains. The second box of 100 balls ranged in weight from 94.4 grains to 95.5 grains. The average was 95.1 grains with a std. dev. of 0.3 grains. The third box containing only 85 balls ranged in weight from 94.0 grains to 94.6 grains. the average for that box was 94.3 grains with a std. dev. of 0.1 grains.

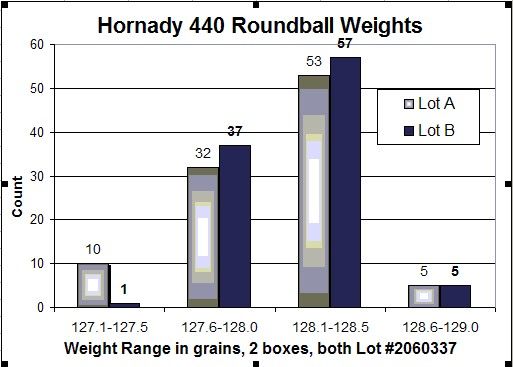

Lastly, a box of 100 Hornady .440 round balls were weighed for consistency. The balls ranged from 130.3 grains to 131.6 grains with an average of 130.9 grains and a std. dev. of 0.3 grains.

All of these Hornady balls had a nice appearance with no obvious defects.

So, comparing my results with yours, my conclusion is that Hornady used to make fairly decent balls but it certainly appears that their quality control has seriously slipped. It makes me wonder if Hornady is actually making the balls themselves or importing them from some place like China. If they are made in China, who the hell knows what they might be melting down and using for lead? I thought all of their lead was being used in exported food, medicine, toys and kids furniture paint. I'm glad I am casting all of my own balls now. Somewhere I have a study on them but I don't have it at hand right now.