I see them on other guys rifles. Looks like it starts out as a 1/2 inch or 7/16ths size for the first several inches and then 3/8ths inch the rest of the way. Lathe? or just scrape/sand it down that way?

Thanks...Bob

Thanks...Bob

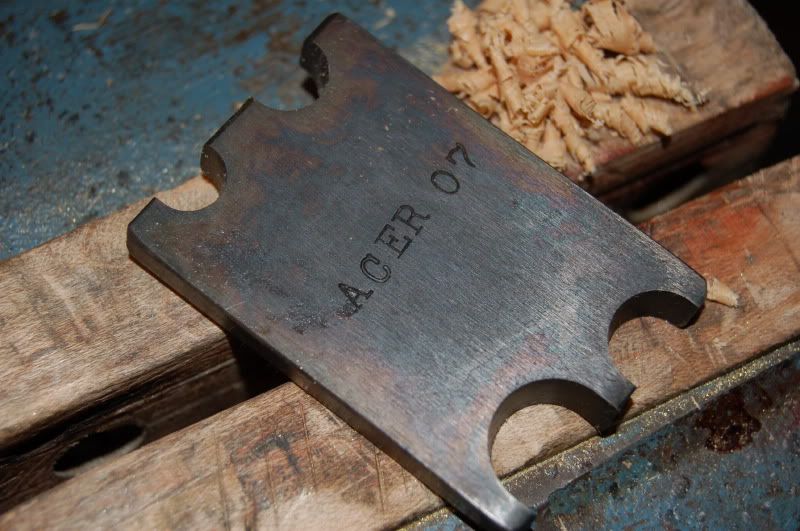

Bill of the 45th Parallel said:Tom generally sells them at shows like Dixons. But you can contact him a www.tomcuran dot com. The tool will let you taper in no time. There's four different cutouts. you just draw the rod thru it.

Bill

Enter your email address to join: