For all you guys that have built such beautiful rifles...

How much woodworking/metalworking experience did you

have before you built your first rifle and if you had no previous experience, how hard was it to learn "on the fly"?

If you had no previous experience before you built your first rifle, which task was the most difficult for you to learn and perform?

Which skill would you recommend that a person develop before starting such a project?

Thanks!

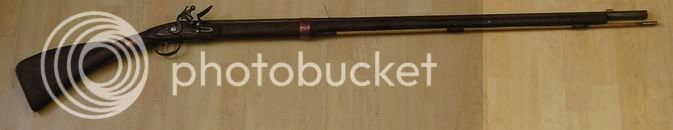

Very little. Prior to making my first rifle, I had carved two toy rifles (slab-sided, not rounded) out of pine and put together a CVA snap-together kit. The kit really didn't teach me anything, really.

The most difficult task (i.e., the one I screwed up most on) was cutting the ramrod groove straight and even. One helpful hint: if you are working from an uncut blank, make sure everything is square and straight, even if you are going to cut it away. I fudged a bit on that, and payed for it. example- when cutting the ramrod groove, instead of making sure that the forearm was perfectly flat where the groove was going to go, I simply tried to make it a little deeper where the wood rose up. :shake: Fortunately, the ramrod hides a multitude of sins, and the ramrod hole didn't come out the side of the stock.

As for which skill to develop- anything you can! drilling straight holes and filing metal flat are two areas which I have trouble in. A drill-press will NOT guarantee a straight hole either- if you are drilling at an angle to the surface with twist-bits, you are better off using a hand-drill and starting at a right angle to the surface and then changing to the desired angle once the tip has bitten in the wood or metal far enough not to skip. try it- it works!

Try to see if there are any gunsmiths in your area that are willing to give you some help. I was mentored through my rifle by one of the locals, and his help saved my rifle once or twice (he drilled my ramrod hole and welded in a patch on my barrel tang when the drill bit flexed while trying to drill for the tang screw, for example. I learned the remedy from watching him drill something else.)

If you have some basic woodworking skills, I think it isn't too hard to build a shootable, if not beautiful, rifle. I did, anyhow, and if I can do it it can't be too hard, right?

eace: